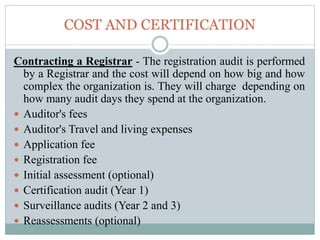

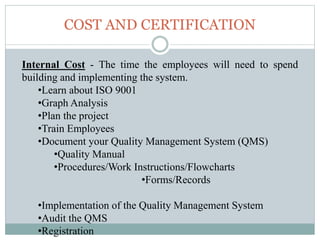

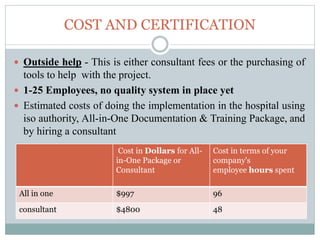

The document discusses ISO 9000 quality standards for hospitals. It explains that ISO 9000 provides a framework for designing quality management systems to improve efficiency and customer satisfaction for healthcare organizations. The key elements for healthcare providers include management responsibility, quality systems, contract reviews, design control, document control, purchasing, product identification, inspections, handling/storage, audits, and statistics. Benefits include uniformity, cost reductions, improved customer satisfaction. Costs include consultant/registration fees, employee time to implement the system.