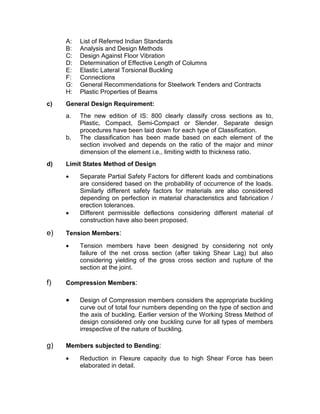

The document summarizes the key changes made in the revised Indian Standard IS: 800 (LSM) for structural steel design. Some major modifications include: [1] The standard now follows the limit state method of design reflecting latest practices; [2] It allows use of new varieties of medium and high tensile structural steels; [3] Design procedures are separated for different types of cross section classifications; [4] Fatigue design and earthquake resistance provisions have been introduced for the first time. The revised standard aims to enhance safety and economy in steel construction.