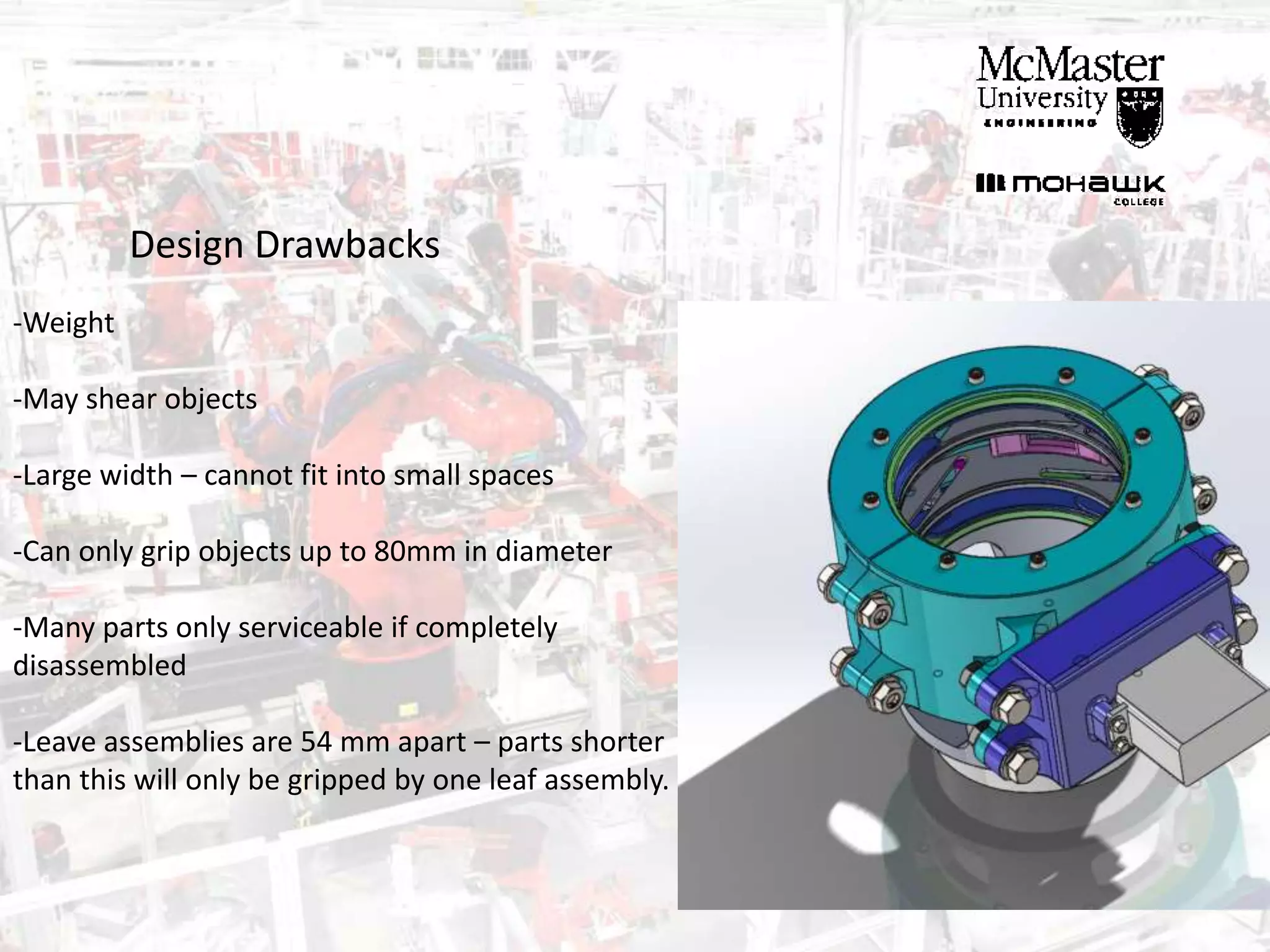

The document outlines the design and development process of a robotic gripper by Jack and Jeremiah Gill for Autotech, focusing on constraints, initial and final designs, and assembly issues. The final design weighs 522.19 grams, comprises 137 parts, and can grip objects up to 80mm wide. Issues such as weight, the gripper's width, and part accessibility are noted as design drawbacks.