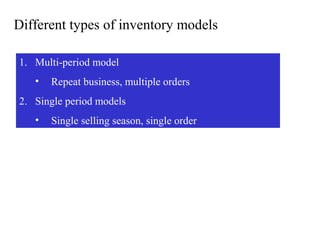

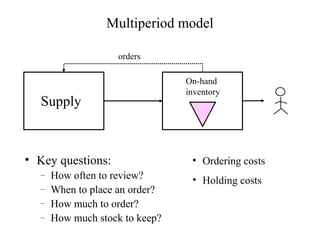

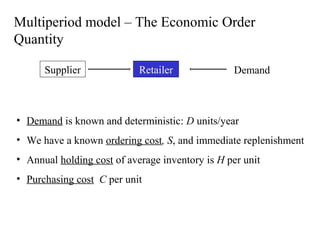

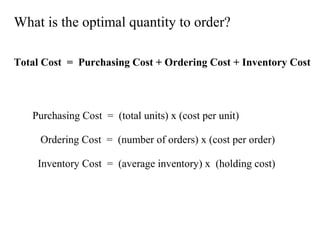

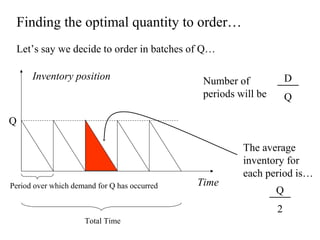

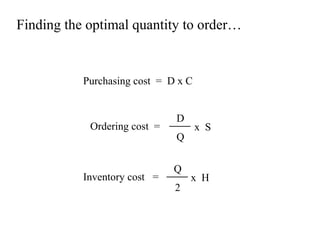

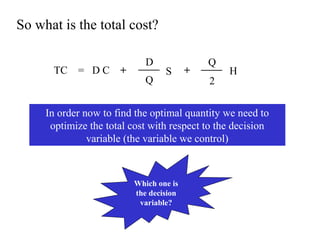

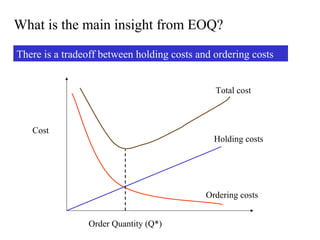

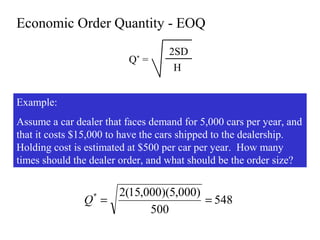

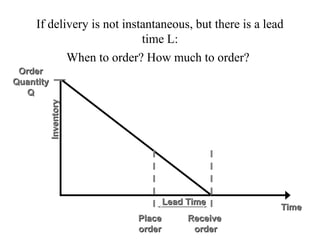

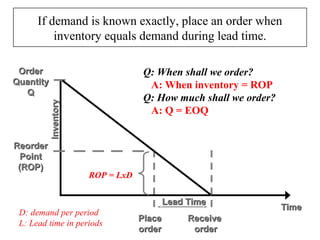

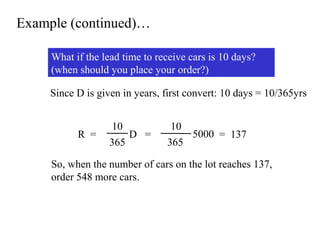

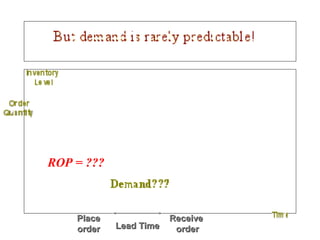

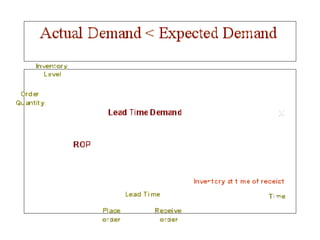

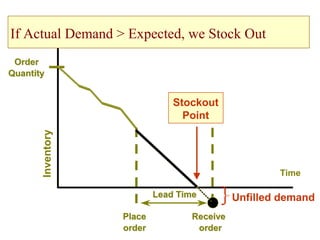

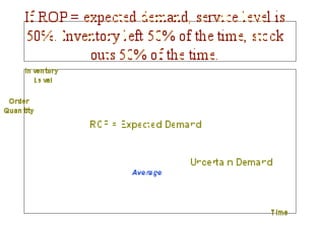

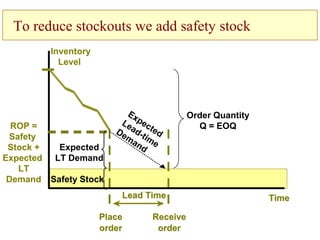

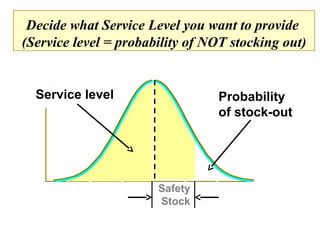

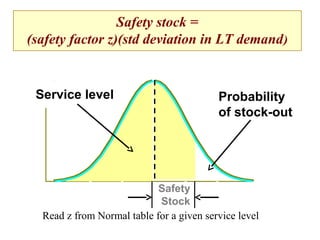

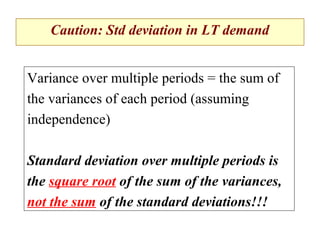

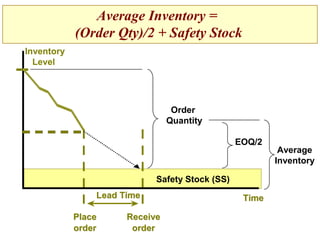

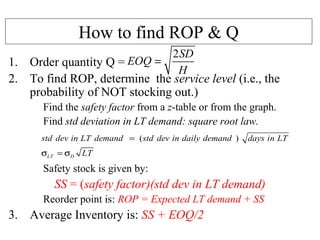

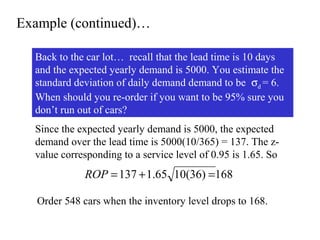

This document discusses inventory management. It defines inventory as raw materials, parts, work in progress, or finished goods held in the supply chain. It notes that inventory represents a large corporate asset and discusses why managing inventory is important at both the macro level, in terms of efficiency gains, and at the firm level to drive sales growth and cost reductions. The document outlines factors to consider in inventory management like costs and benefits. It describes economic order quantity modeling and key insights around balancing ordering and holding costs. It also discusses reorder points, lead times, safety stock, and how to determine optimal order quantities and reorder points.