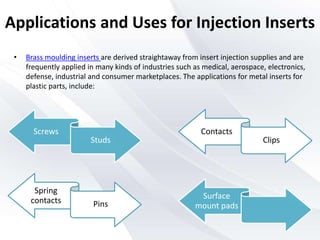

Insert molding is a manufacturing process where plastic is injected into a mold that contains pre-placed metal inserts, typically made of brass, resulting in stronger, more durable components. This method is cost-effective, reliable, and applicable across various industries including automotive, medical, and electronics, offering design flexibility and reduced assembly costs. The advantages of insert molding include dimensional accuracy, rust resistance, and the ability to create complex geometries, making it a preferred choice in modern plastic injection molding technologies.