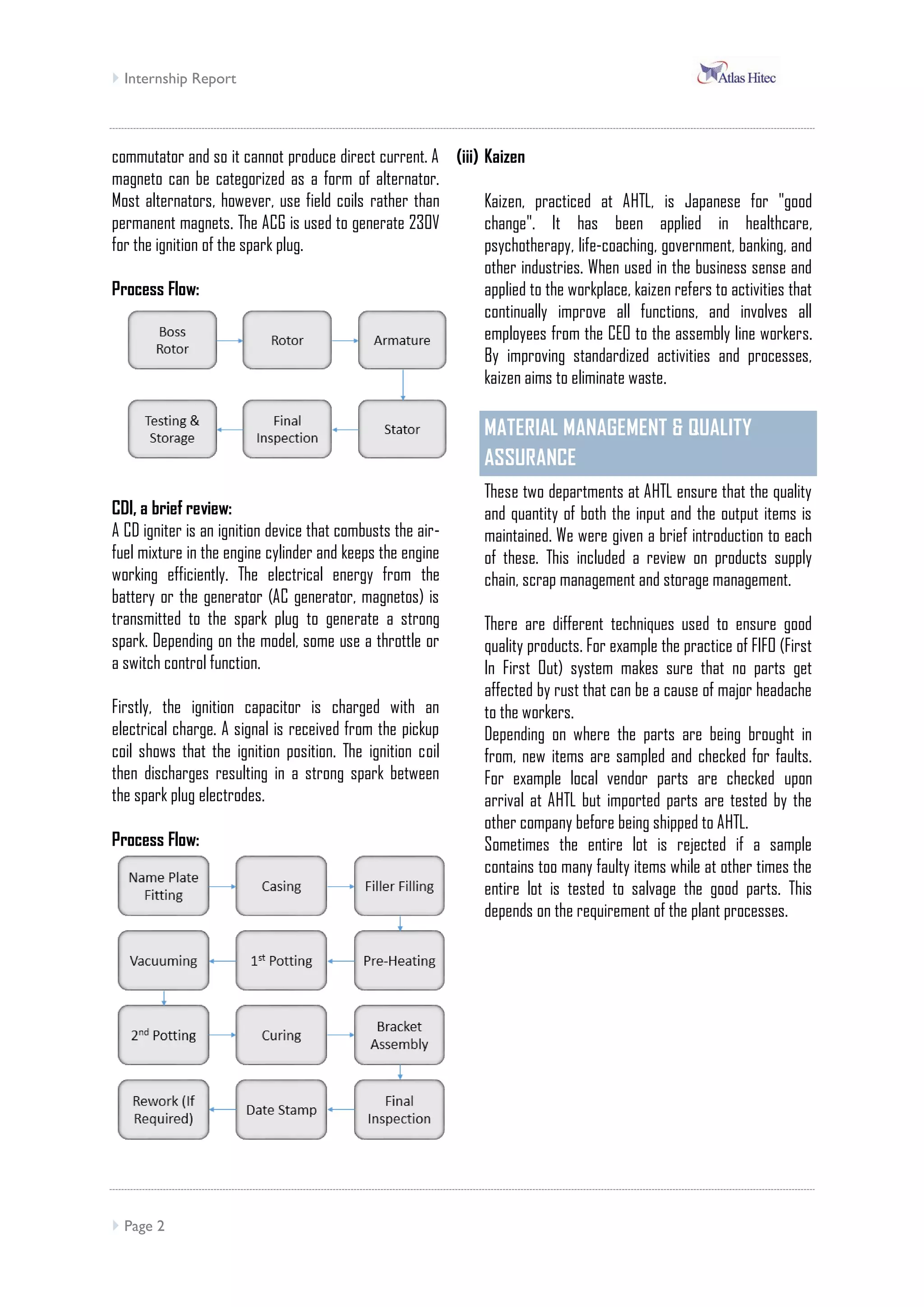

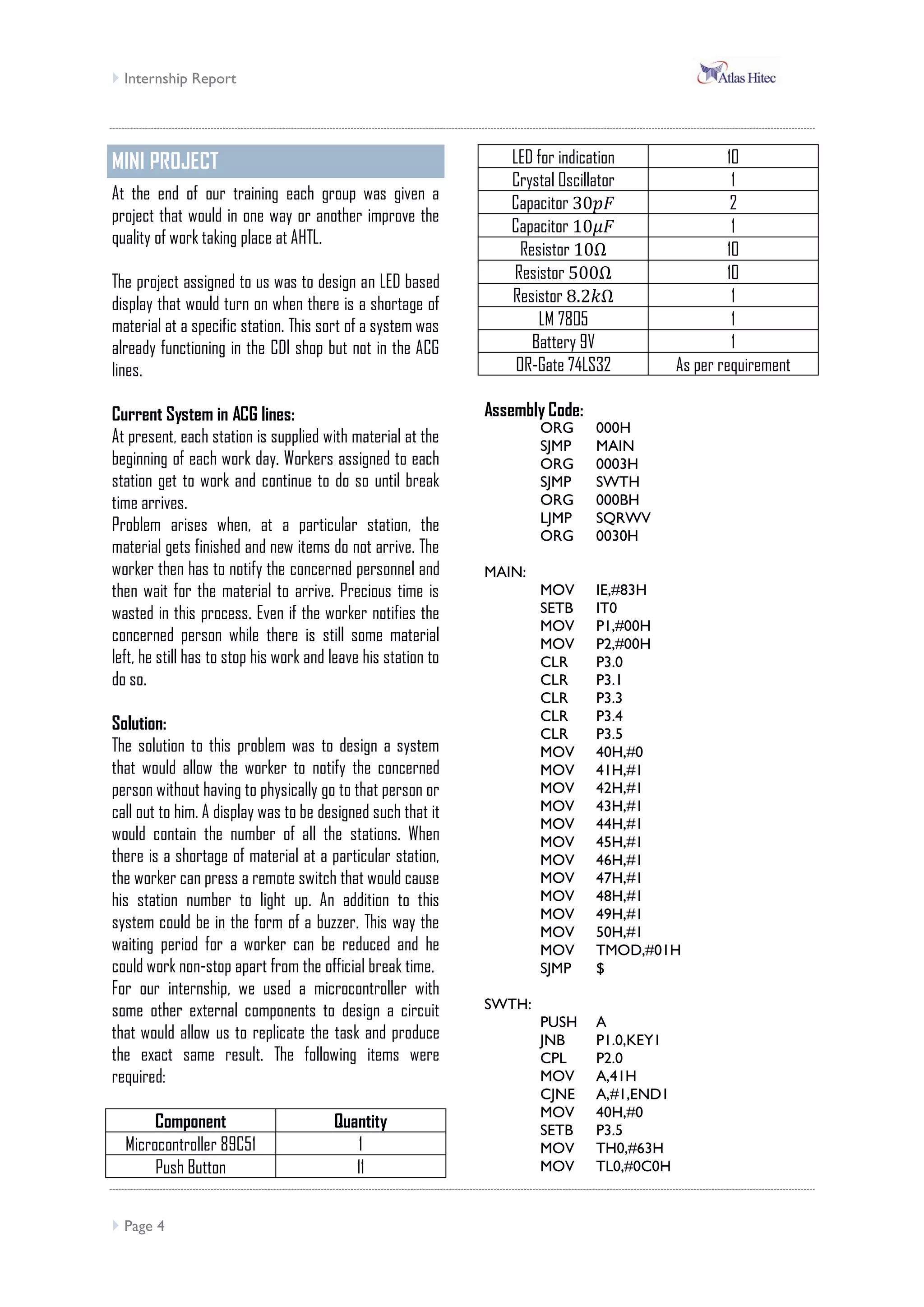

The document is an internship report submitted by five students who completed internships at Atlas Hitec (Private) Limited from July 4th to August 8th. It summarizes their experiences, including an overview of the company and its products, general education training on topics like 5S and product processes, process training, and a mini project to design a material shortage display system. It concludes with recommendations for minor improvements observed during the internship.