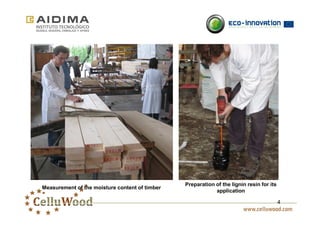

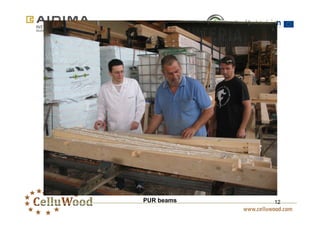

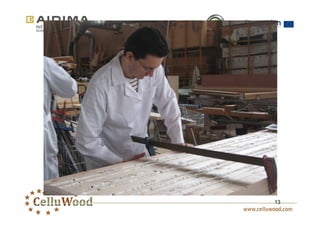

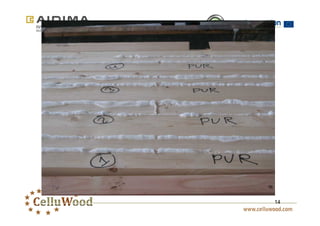

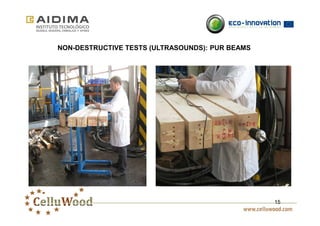

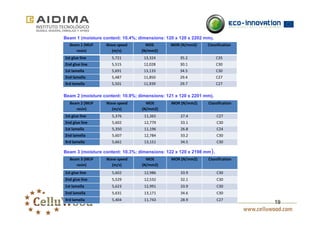

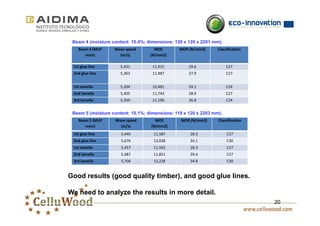

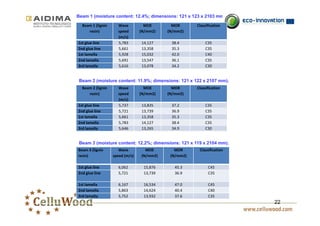

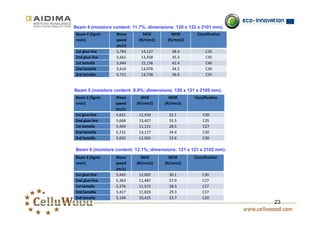

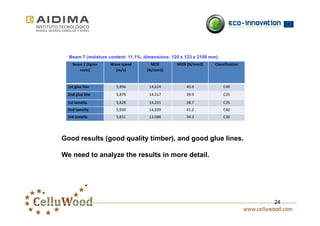

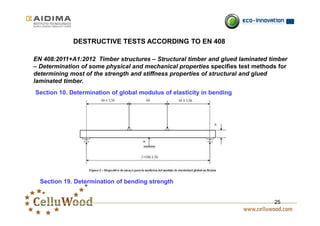

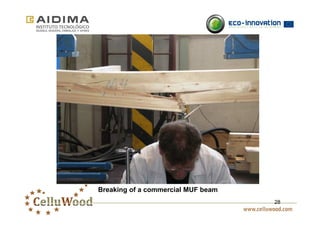

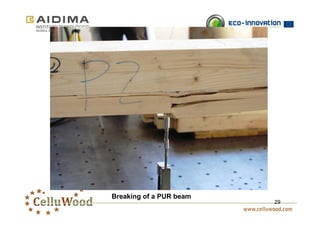

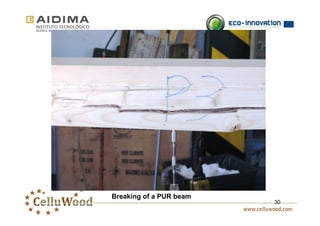

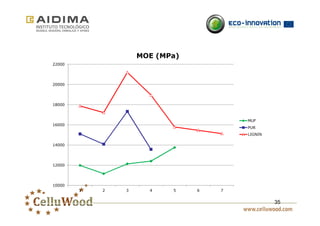

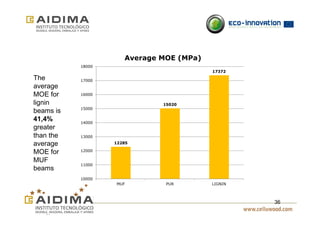

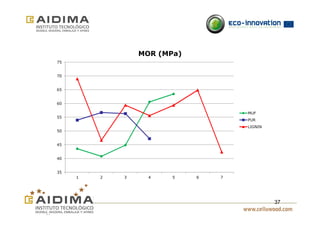

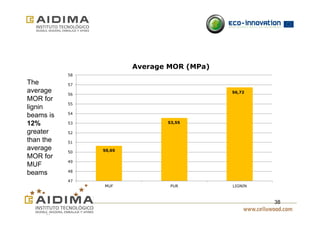

The document discusses the interim tests conducted on Celluwood materials during a project meeting held in Valencia in July 2014. It details the manufacturing and testing of both lignin resin and commercial MUF beams, including measurements of their physical properties and strength. The results show that lignin beams exhibited superior average modulus of elasticity and bending strength compared to MUF beams, indicating their potential for improved performance in construction applications.