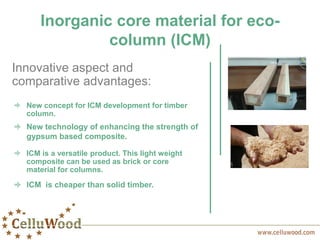

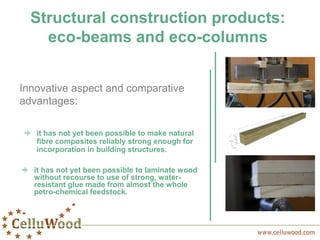

The Celluwood project aimed to innovate environmentally friendly building materials using cellulose-strengthened wood, focusing on lignin-based adhesives and nanocellulose bio-resins for eco-beams and eco-columns. The project produced notable products, including a lignin-based gluing system with lower emissions, and an inorganic core material for columns, utilizing wood residues. Overall, the project achieved significant advancements in sustainable construction technologies that can be implemented without extra investment in production facilities.