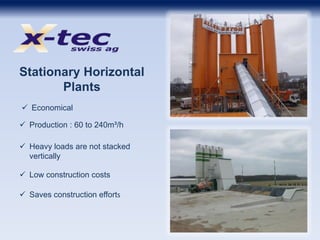

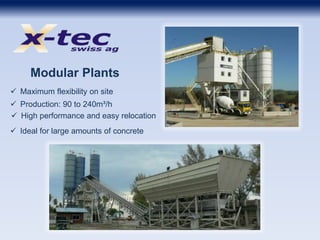

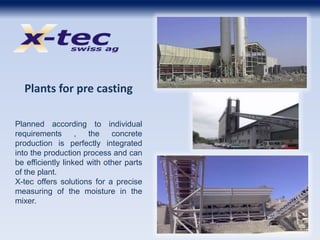

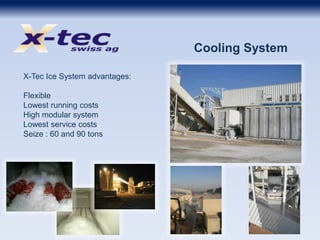

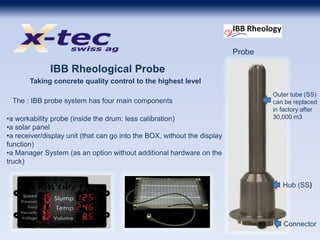

X-Tec Swiss AG is an international supplier of concrete plants, heating and cooling systems founded in 1990. It has a worldwide market presence and offers modular, economical plants tailored to customer requirements. Notable past projects include works for Holcim, Leighton Contractors, and airports in Dubai and Germany. X-Tec's product lines include stationary tower, horizontal, and mobile concrete plants, as well as pre-casting systems. It innovates with technologies like an automatic rheological probe for real-time concrete monitoring and has goals of constant improvement, innovation, safety, and customer satisfaction.