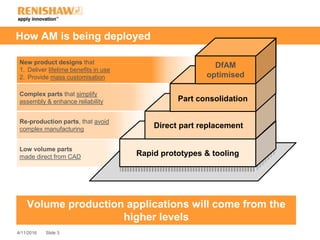

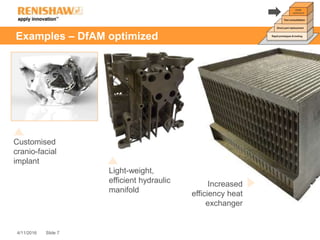

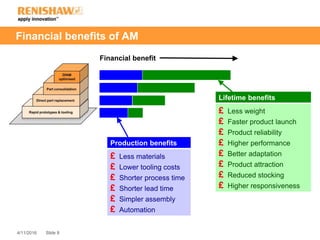

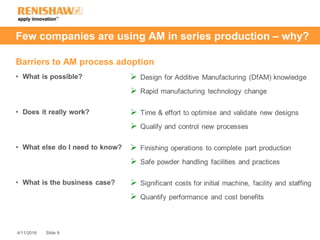

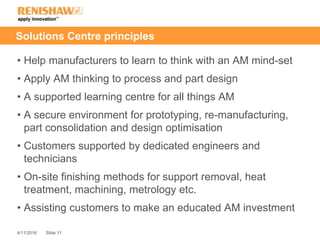

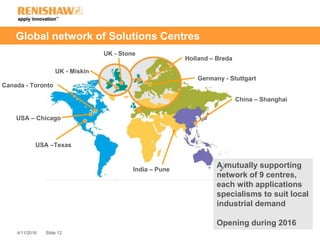

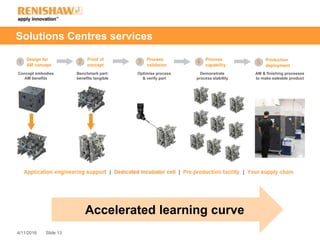

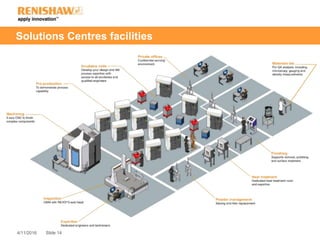

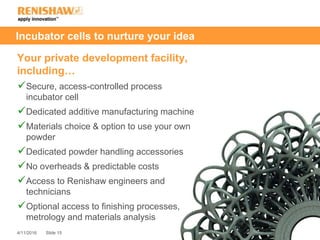

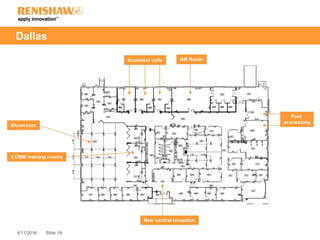

The document discusses the advantages and deployment of additive manufacturing (AM), highlighting its potential for innovative design, material efficiency, and rapid prototyping. It details the services provided by global solutions centers aimed at helping manufacturers optimize their AM processes and part designs, while also offering support and facilities for pre-production and development. Ultimately, it emphasizes the financial benefits and overall improvements that AM can bring to various industries.