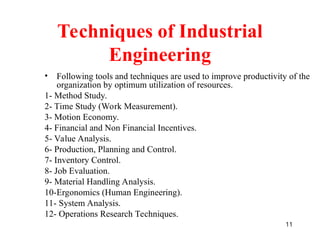

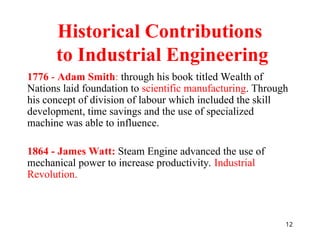

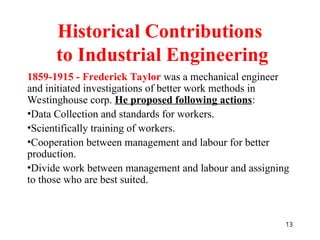

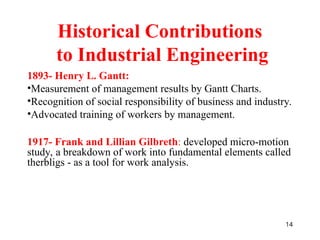

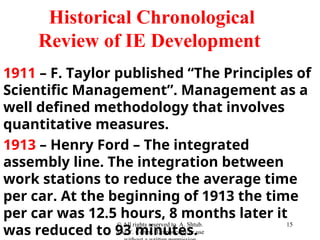

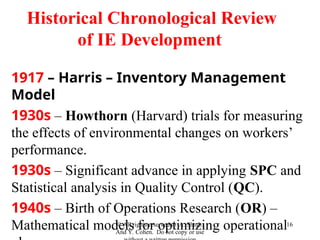

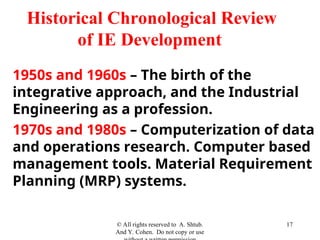

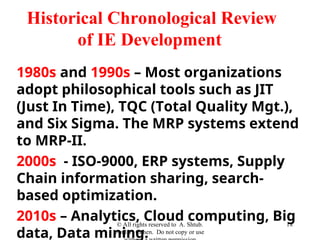

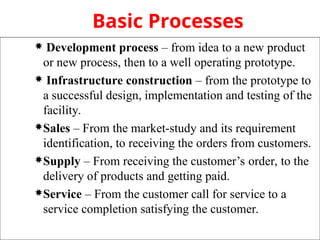

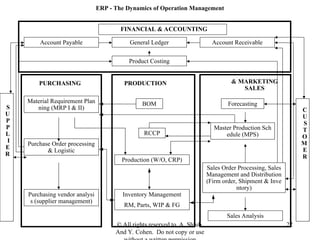

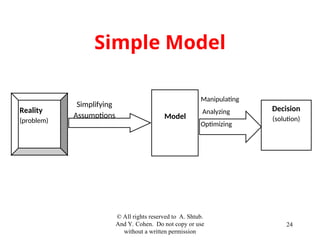

The document serves as an introduction to industrial engineering (IE), detailing its significance in optimizing organizational operations in both manufacturing and service sectors. It outlines key objectives of IE, including improving productivity and resource utilization, and discusses various tools and techniques employed by industrial engineers. The narrative further delves into historical contributions to the field and emphasizes the evolving dynamics of operation management, reflecting on the increasing importance of customer satisfaction in a competitive market.