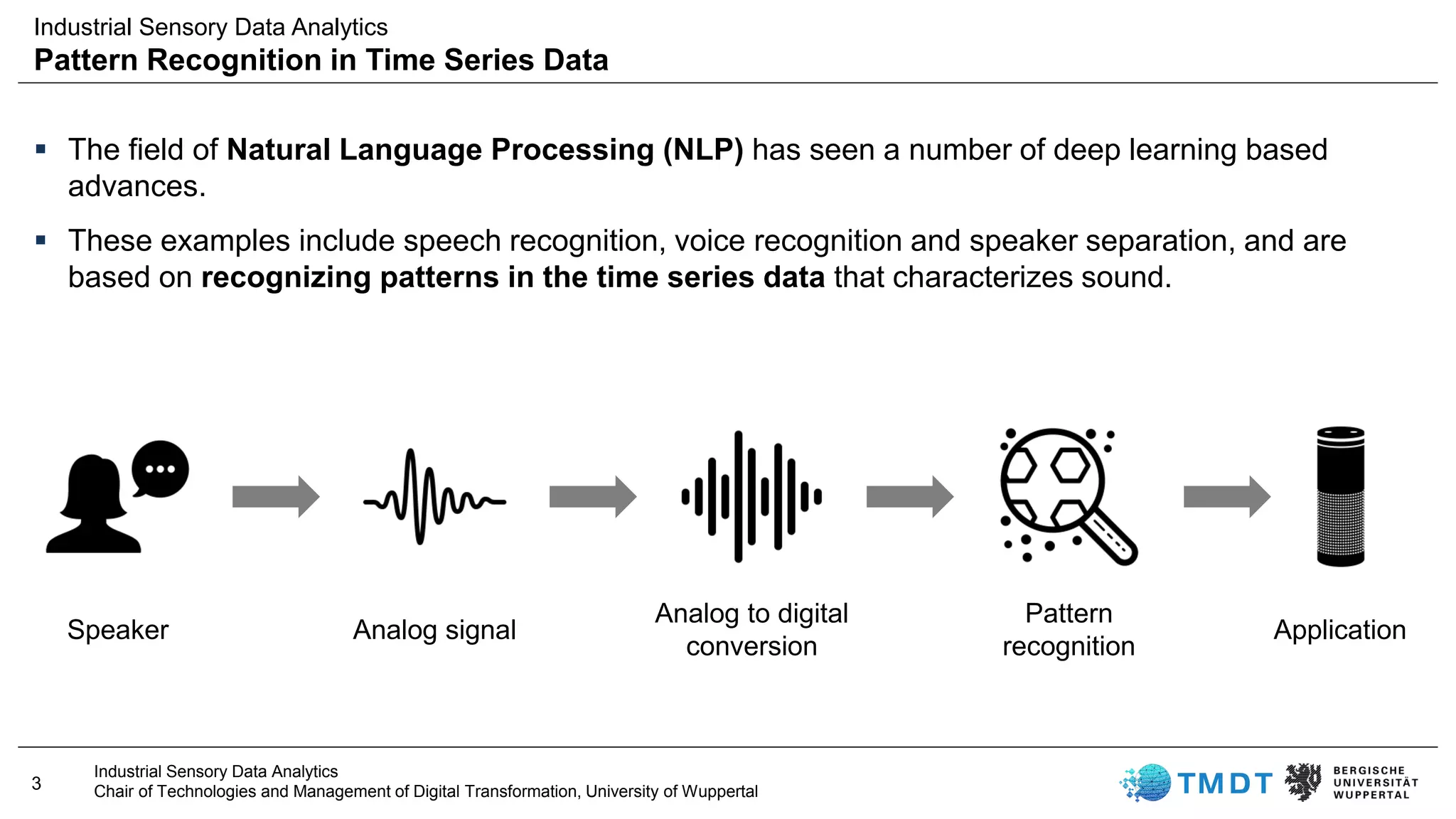

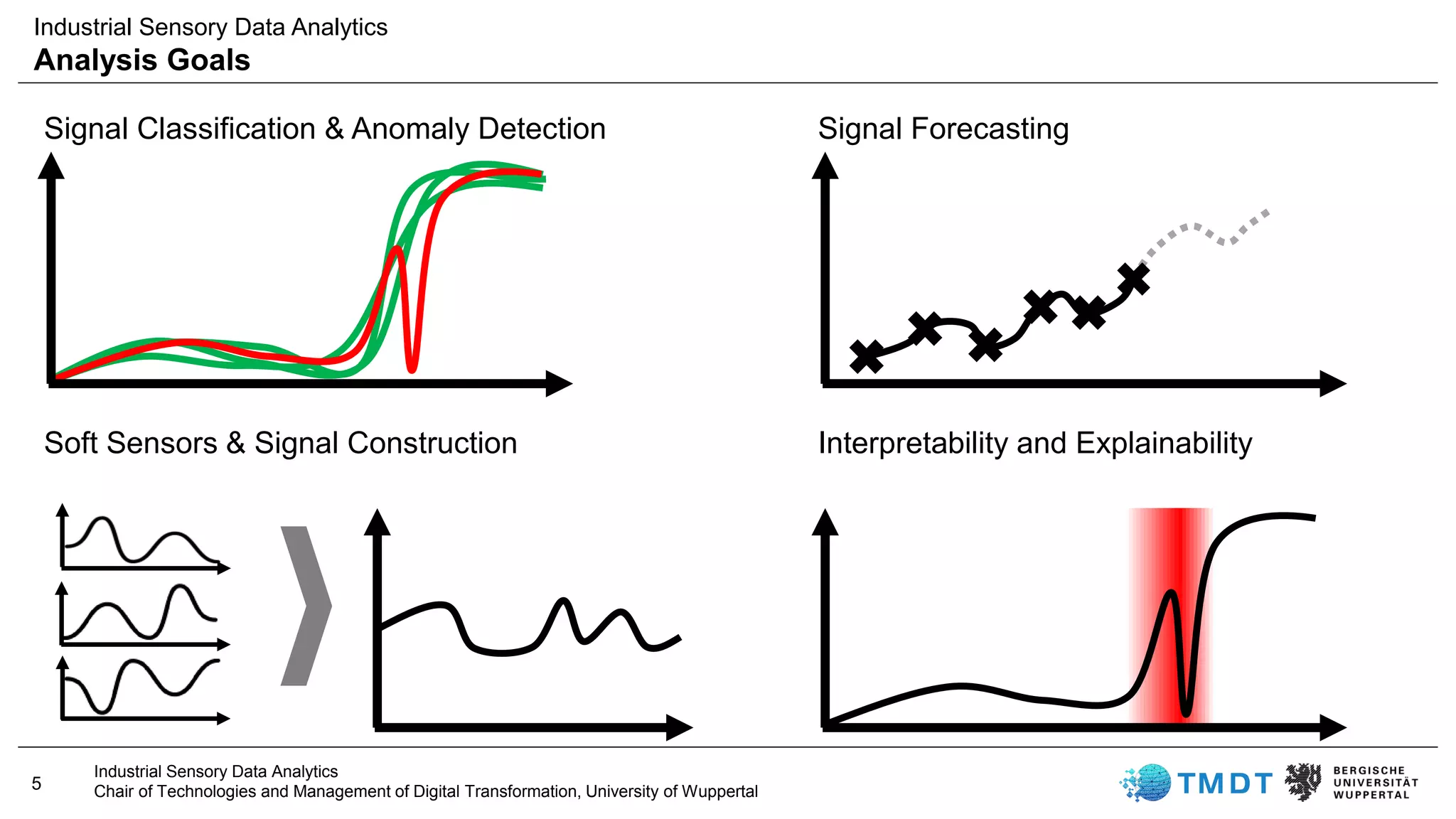

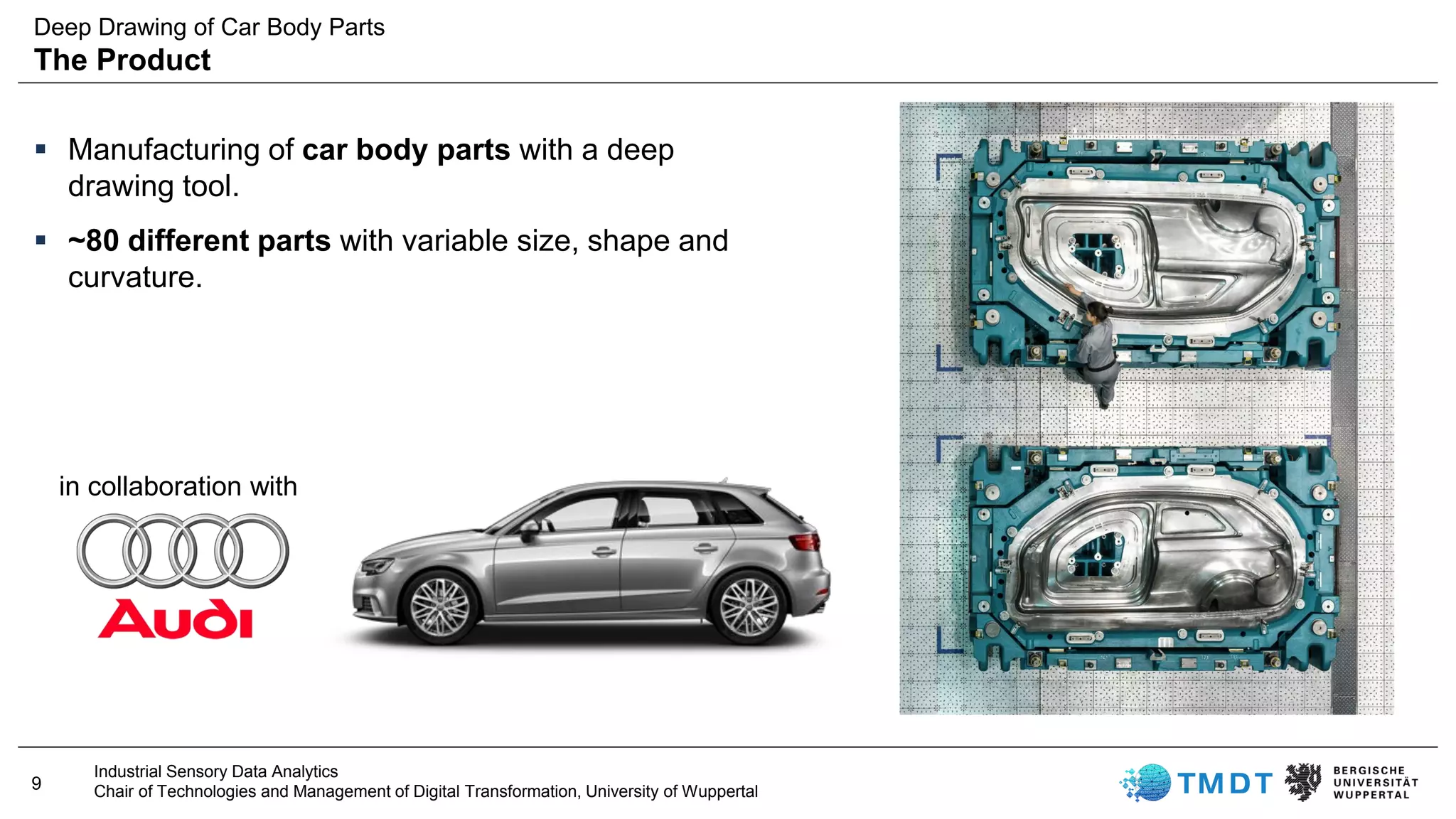

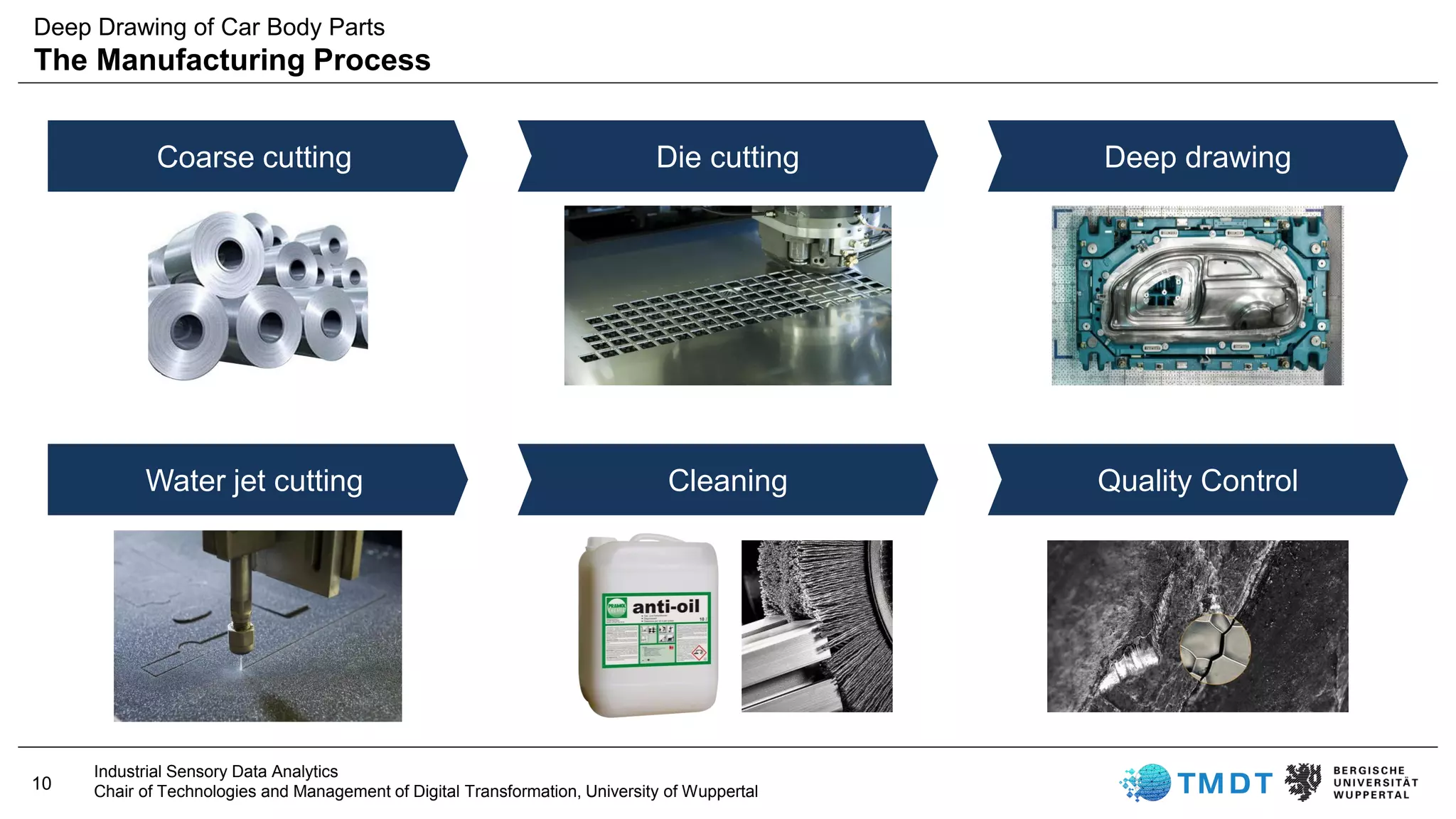

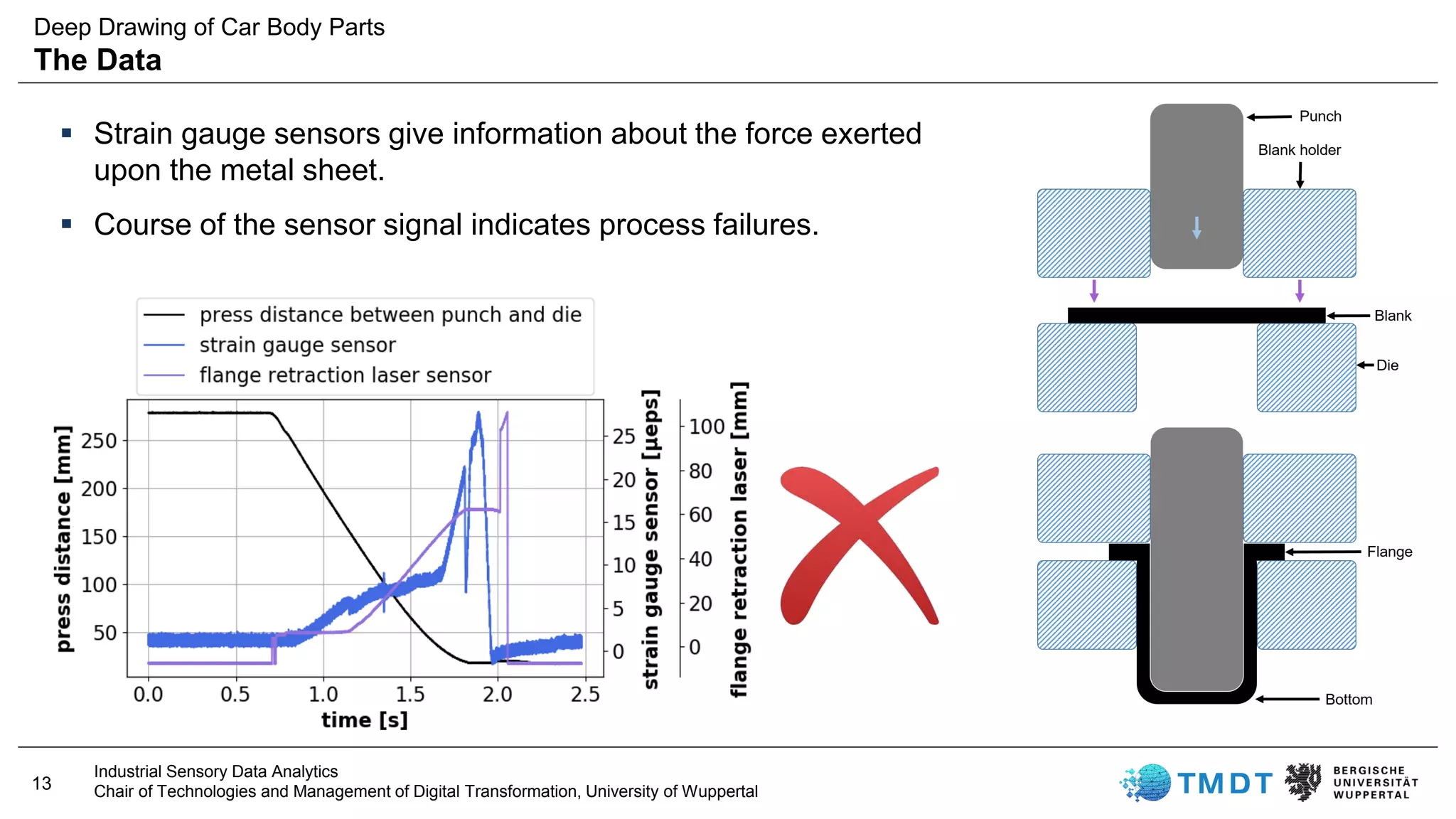

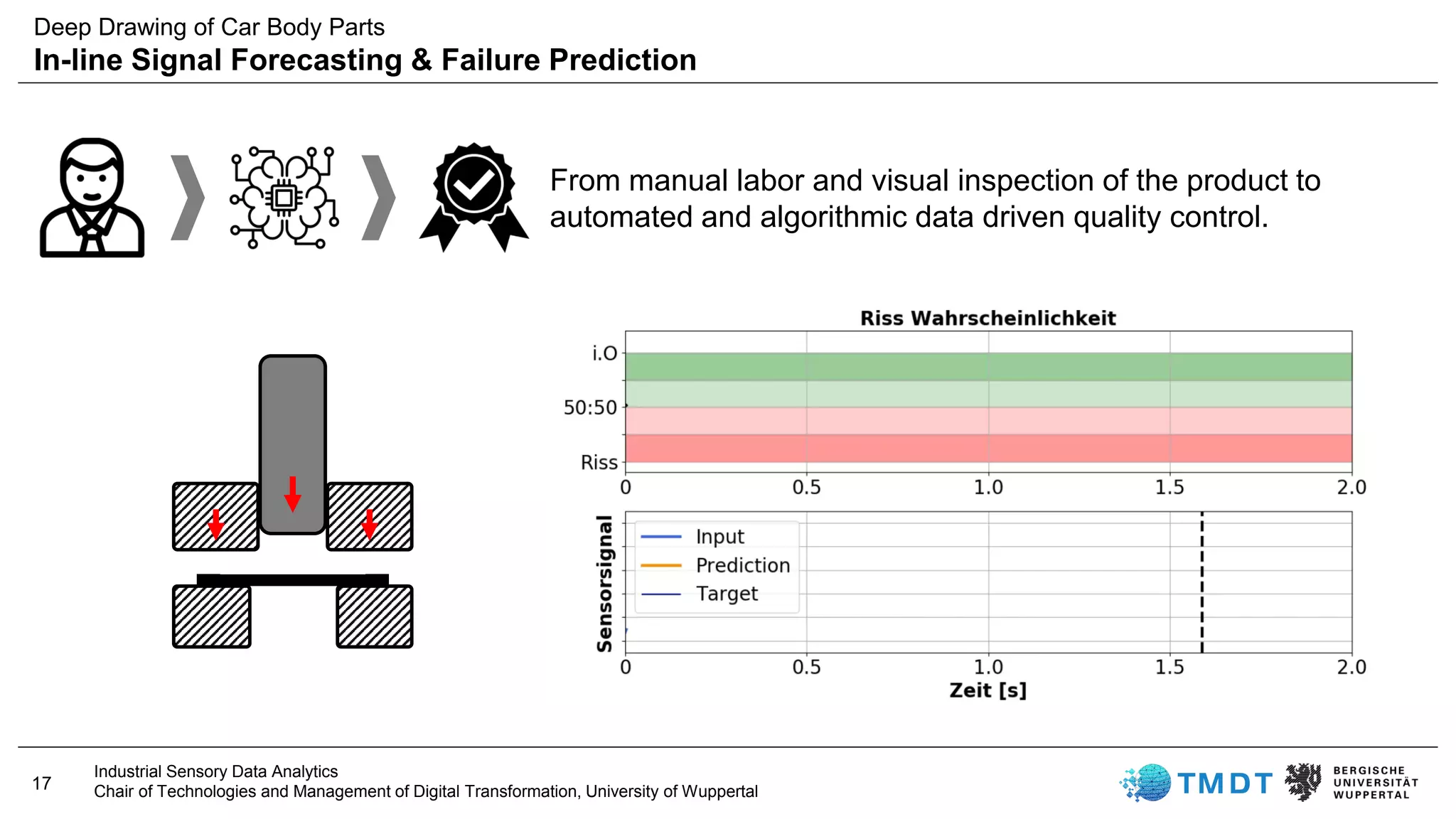

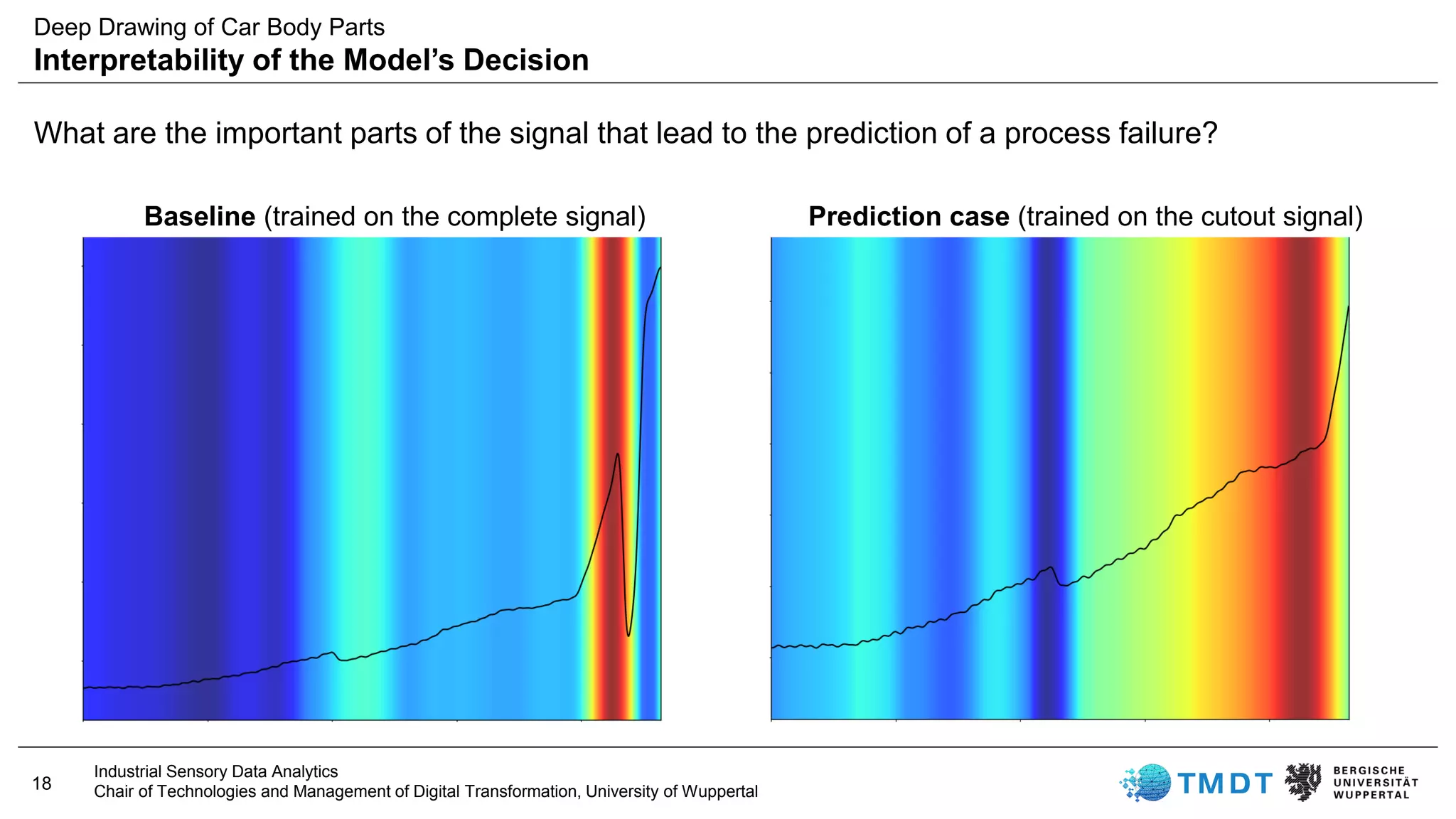

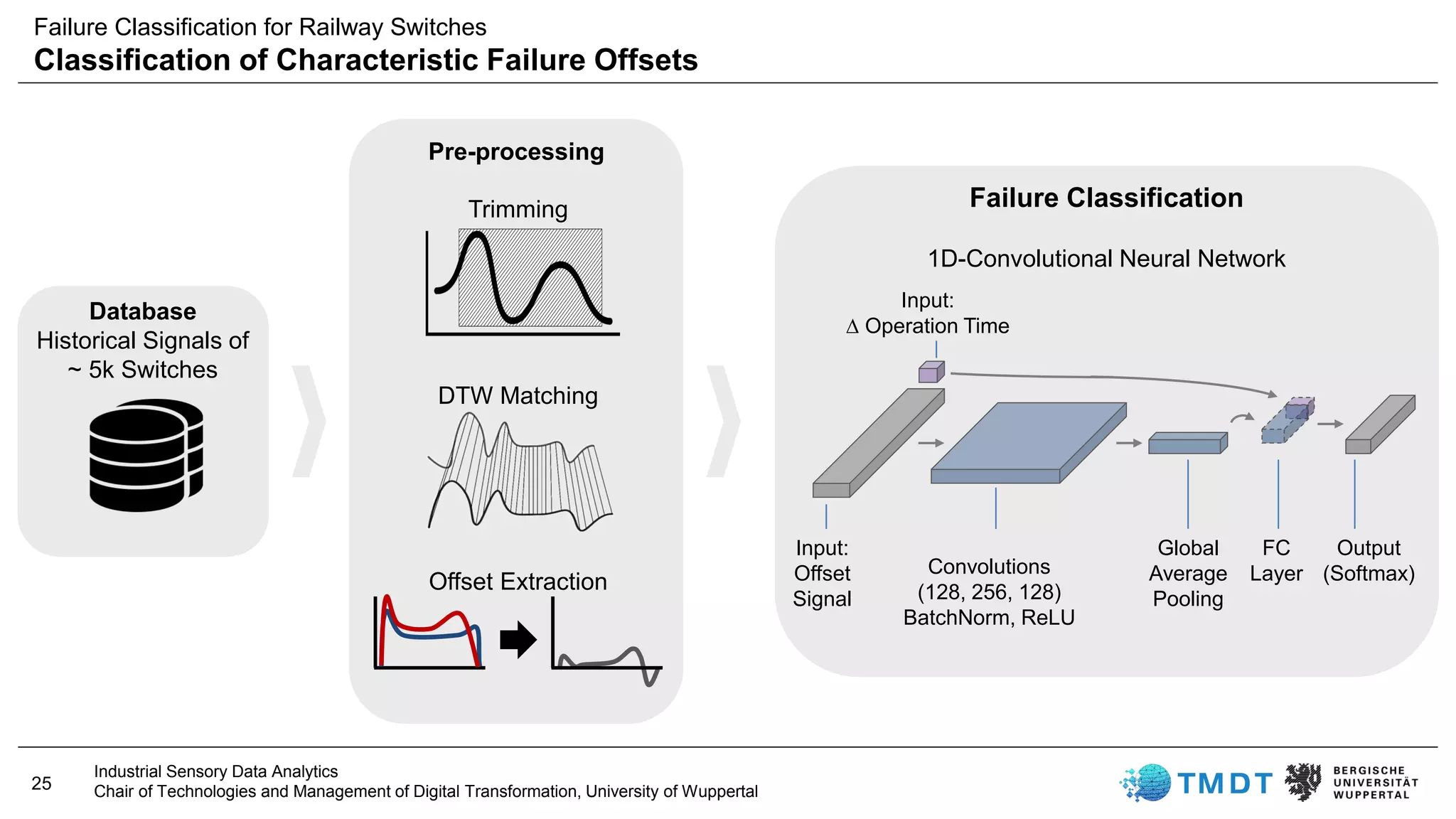

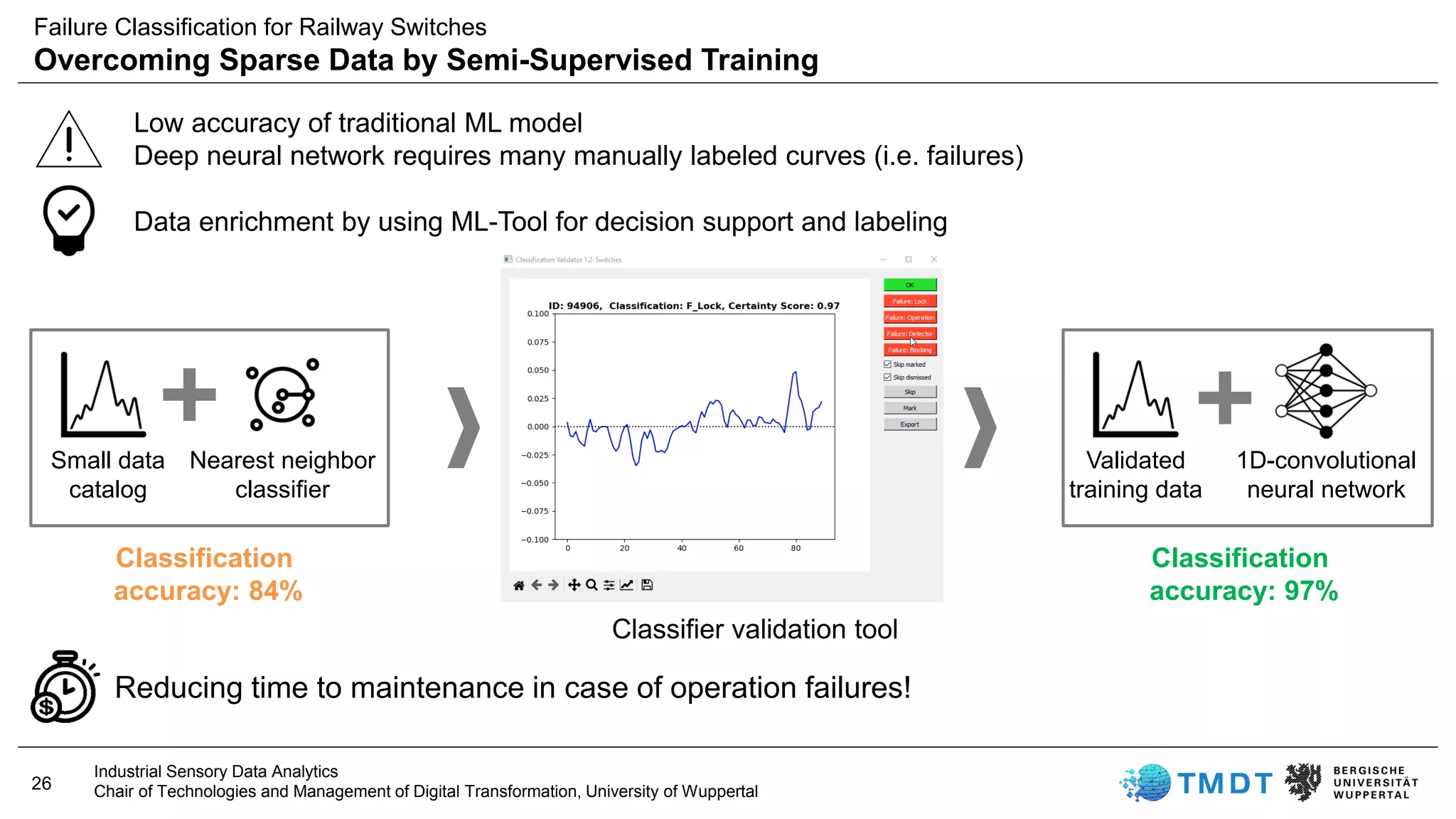

The document discusses industrial sensory data analytics focused on pattern recognition in time series data, leveraging deep learning techniques for applications such as process monitoring and failure prediction in manufacturing. It highlights research projects in sectors like automotive and railway, demonstrating the use of machine learning for anomaly detection and quality control. Key methods include supervised and unsupervised learning, with an emphasis on interpretability and the development of soft sensors to optimize production processes.