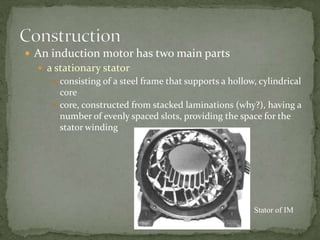

This document discusses three-phase induction motors. It describes their common use in industry due to their simple and rugged design. It explains that induction motors run at a constant speed from no-load to full-load. Variable speed control requires an adjustable frequency power supply. The motor has a stationary stator and a revolving rotor, which can have either wound or squirrel cage windings. A rotating magnetic field from the stator induces currents in the rotor to generate torque. Induction motors always run slightly slower than synchronous speed due to slip.