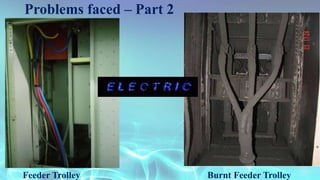

This document discusses modifications made to an incinerator plant at an IFFCO fertilizer unit in Phulpur, India. The plant previously had issues with loose jaw contacts causing downtime and the inability to independently operate motors. The implemented solution added modified spacers to address loose contacts and interfacing to allow independent motor operation. This resulted in annual savings of over 1.97 crore rupees from reduced downtime and lower energy costs. The author was recognized and awarded for their suggestions through IFFCO's creativity program.