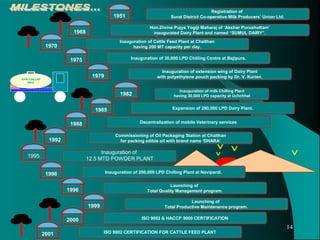

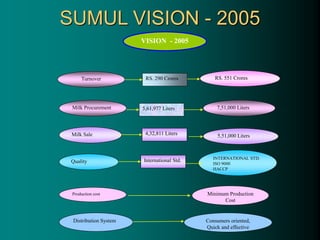

Sumul Dairy was established in 1951 by milk producers in Surat, India to gain fair prices and combat exploitation by private milk traders. It has since grown to include multiple processing plants, chilling centers, and a cattle feed factory. Sumul Dairy was awarded a Certificate of Merit in 2003 for quality. The summary focuses on the cooperative's origins, growth over time, and recent recognition for quality.

![11

O

O

O

O

O

O

O O

O

O

O O

O

O

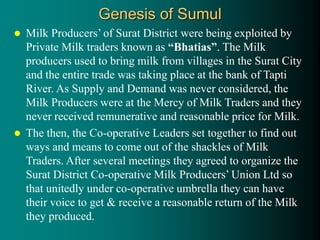

Cream

Homogenizer

CREAM

SEPARATOR

CREAM

40% FAT

WHOLE

MILK

(6.5 / 9.0)

TEMP.

+ 50 C

M I L K C O L D S T O R E

P A S T E U R I Z E R

[ Heating to 800C & Cooling to 40C ]

C H I L L E R

TRIBAL VILLAGE

COOPERATIVE SOCIETY

O O

O

O

O

O

O

O

O O

O

O

O O

O

O

M I L K

CHILLING PLANT

O

O

O

O O

O

O

O O

O

O

POUCH FILLING

MACHINES

M I L K

P.S.M.

MILK

(4.5 /8.5)

M I L K

8OC 4OC

8OC

C I T Y

MILK

MILK](https://image.slidesharecdn.com/imcpres-220723054445-de3a1a37/85/IMCPRES-PPT-11-320.jpg)

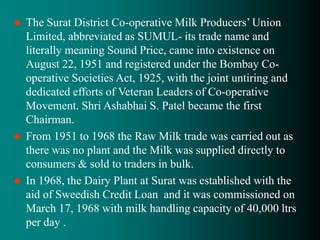

![MAIN

DAIRY PLANT

CATTLE FEED

FACTORY-CHALTHAN

MANGROL

B H A R U C H

S E R V I C E S :

1. CATTLE FEED PRODUCTION

2. VETERINARY SERVICES

3. ARTIFICIAL INSEMINATION

4. CO-OPERATIVE DEVELOPMENT

5. EXTENSION ACTIVITIES

6. MILK PROCESSING

& MILK PRODUCTS MANUFACTURE

7. MILK DISTRIBUTION

CHILLING CENTRE

km distance from Surat

CATTLE FEED FACTORY

TALUQA / TEHSIL NAME

UMARPADA

UCHCHHAL

VYARA

MANDVI

VALOD

MAHUVA

PALSANA

BARDOLI

KAMREJ

CHORYASI

OLPAD

NIZAR

DEDIAPADA

135 km

CHASWAD

100 k m

UCHCHHAL

CHILLING

CENTRE

100 km

BAJIPURA

CHILLING CENTRE

[Diagnostic Lab]

50 km

NAVIPARDI

CHILLING

CENTRE

28 km

NIZAR COMPLEX

165 km

MAIN DAIRY PLANT

U K A I

D A M

SONGADH

WORK AREA OF SUMUL](https://image.slidesharecdn.com/imcpres-220723054445-de3a1a37/85/IMCPRES-PPT-13-320.jpg)

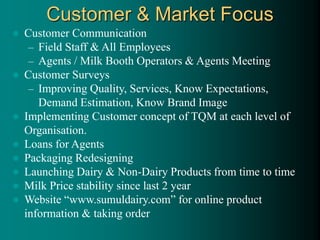

![Cooperative Focus

Maximum Return to our Producers

Developmental Programs

– Organization of new DCS (Village milk co-op soc)

– Milk procurement and milk route transportation

– Milk competition at taluka level and district level.

– Cattle feed competition

– Artificial insemination

– Breed improvement program(DIPA)

– 24 hours mobile veterinary services at door step of producer members (route

and special visit)

– Disease diagnostic laboratory

– Vaccination program for disease prevention at subsidies rate.

– Distribution of balance cattle feed (sumul dan) at no profit no loss basis

– Hybrid fodder seed distribution at subsidies rate.

– Electric chaff cuttersuda at subsidies rateWomen Dairy Co-operative

Leadership Development Programe

– Women seminar

– School Education program

– Film show for Profitable Dairy business at village level

– Monthly bulletin for Milk business [ SUMUL SETU ]](https://image.slidesharecdn.com/imcpres-220723054445-de3a1a37/85/IMCPRES-PPT-27-320.jpg)