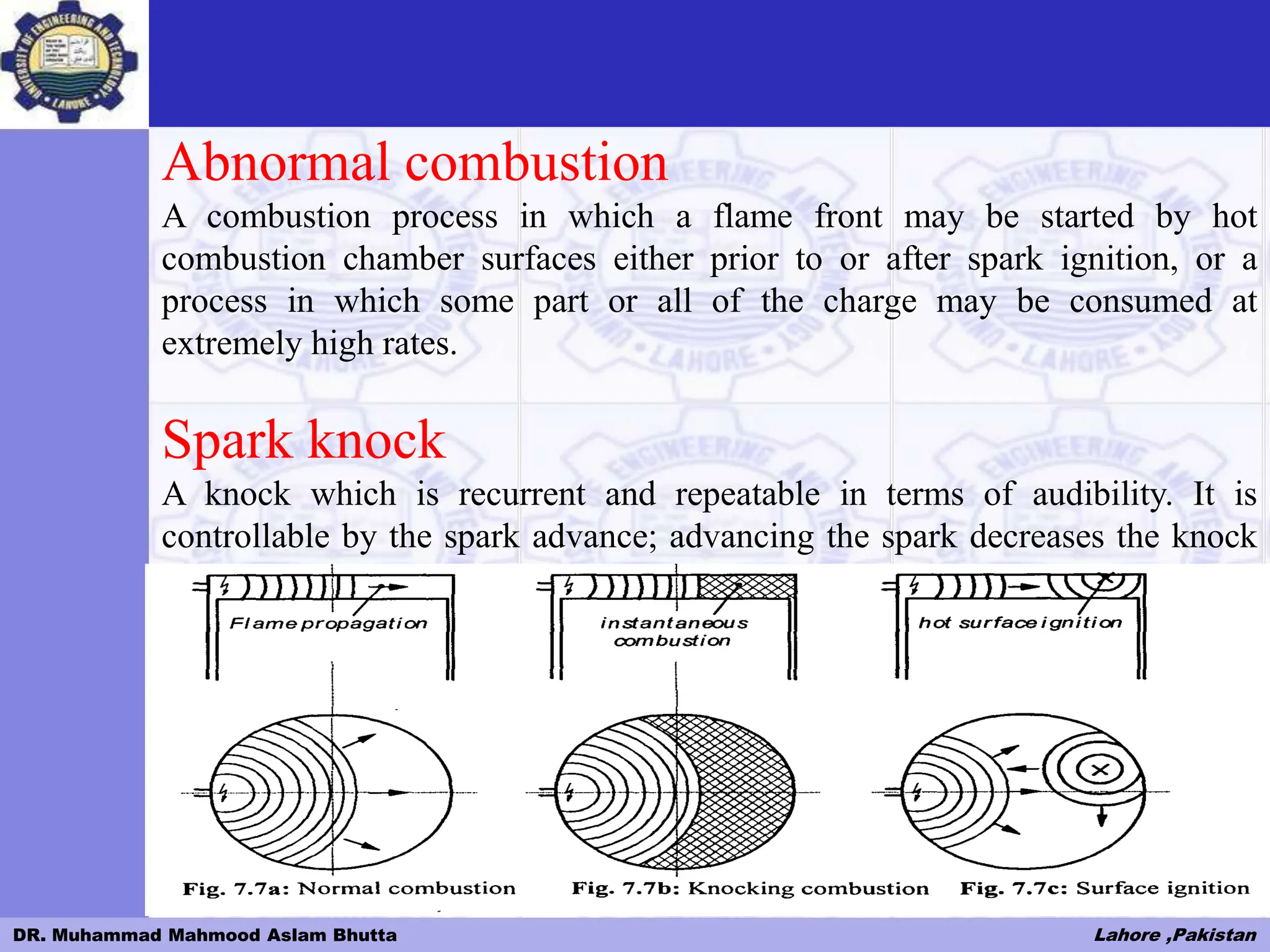

The document discusses key concepts related to fuel ignition including self-ignition temperature, flash point, and ignition quality, highlighting their significance in determining fuel performance. It also explains octane and cetane ratings, which measure a fuel's resistance to knocking and readiness to auto-ignite, respectively, alongside methods for testing these properties. Finally, it covers issues related to engine knock, its causes, types, and strategies to mitigate its effects on engine performance.