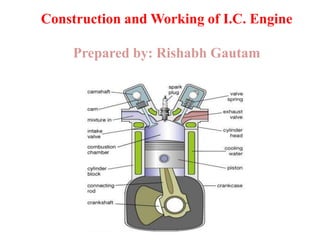

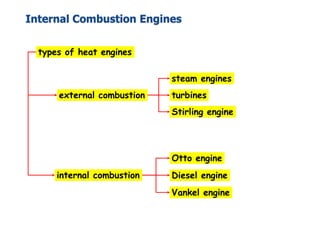

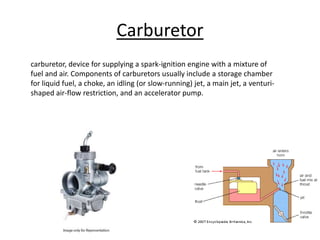

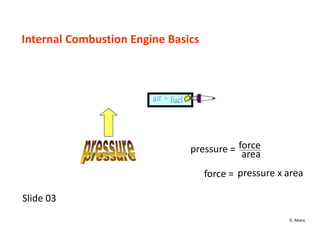

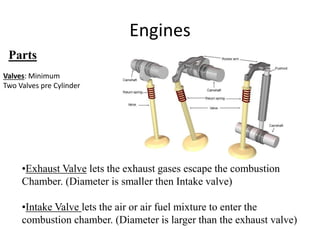

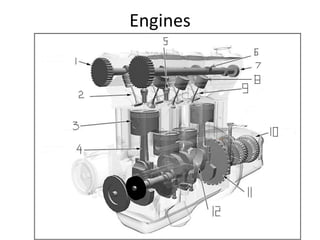

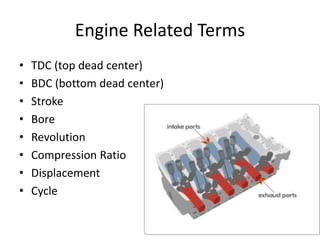

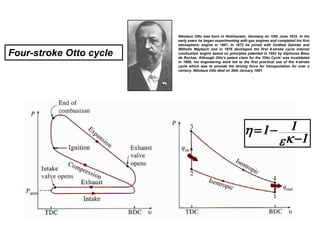

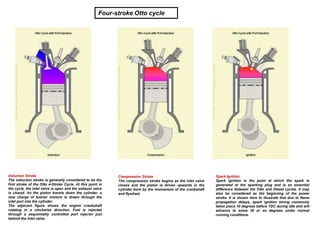

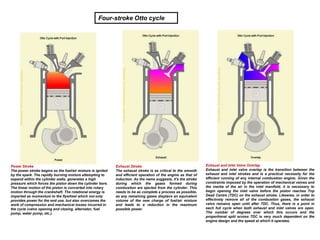

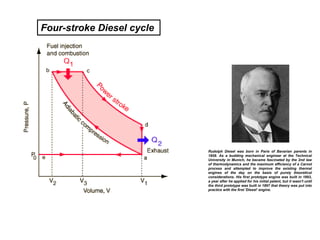

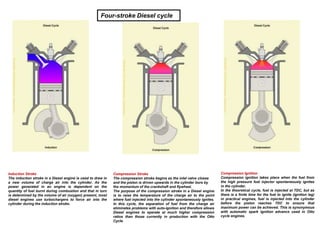

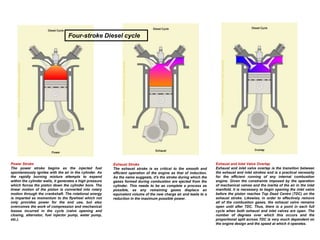

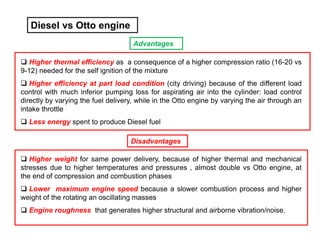

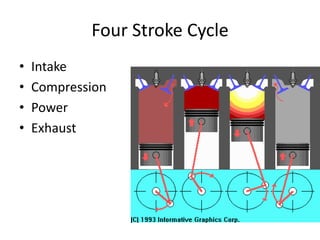

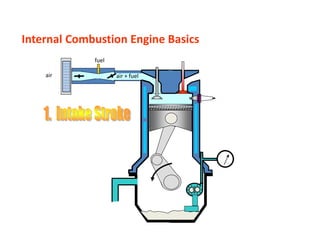

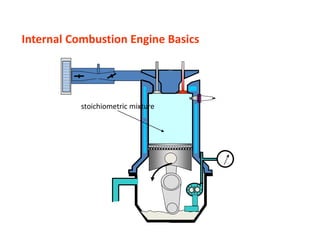

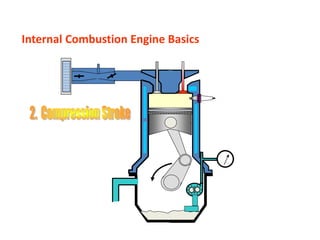

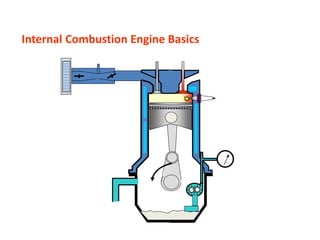

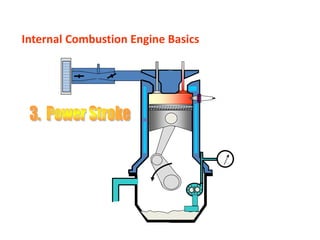

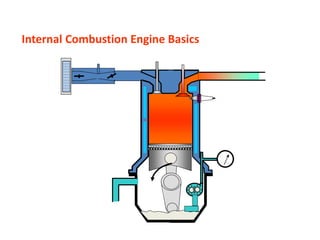

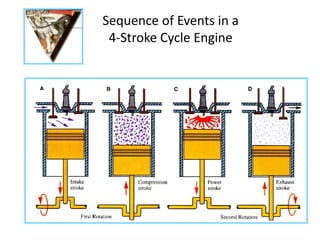

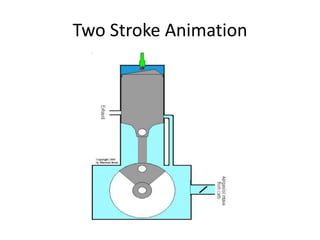

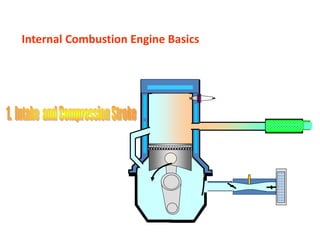

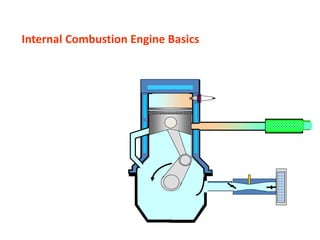

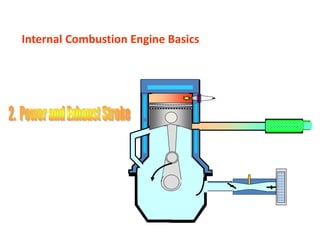

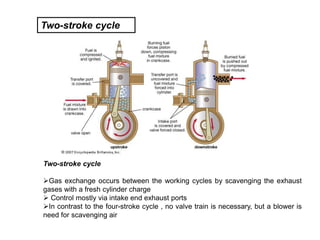

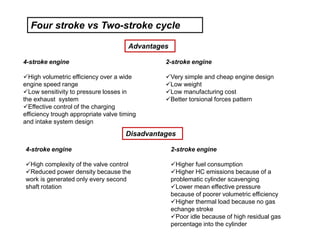

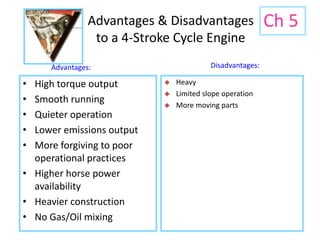

The document provides an overview of internal combustion engines, including types such as Otto and Diesel engines, their working principles, and key components like the carburetor and valves. It explains the fuel combustion process in a four-stroke cycle and contrasts it with the two-stroke cycle, detailing the advantages and disadvantages of each. Additionally, it highlights historical figures like Nikolaus Otto and Rudolf Diesel, emphasizing their contributions to engine development.