This document provides an overview of safety and security topics related to basic industrial wiring. It discusses the physiological effects of electricity on the human body, including how electric current can cause heating, damage nerves and tissues. Threshold values for electric sensation, the ability for a person to let go, and ventricular fibrillation are defined. The main causes of electric shocks are also examined, such as inappropriate operating modes, lack of awareness of risks, and inadequate training. Formulas are provided to calculate body impedance and the current that will flow through the body depending on voltage exposure. The various effects of electric current on the body are also summarized.

![[Didactic Equipment]

[Industrial

Automation

– Part 1

Installation]

[Safety and Security –

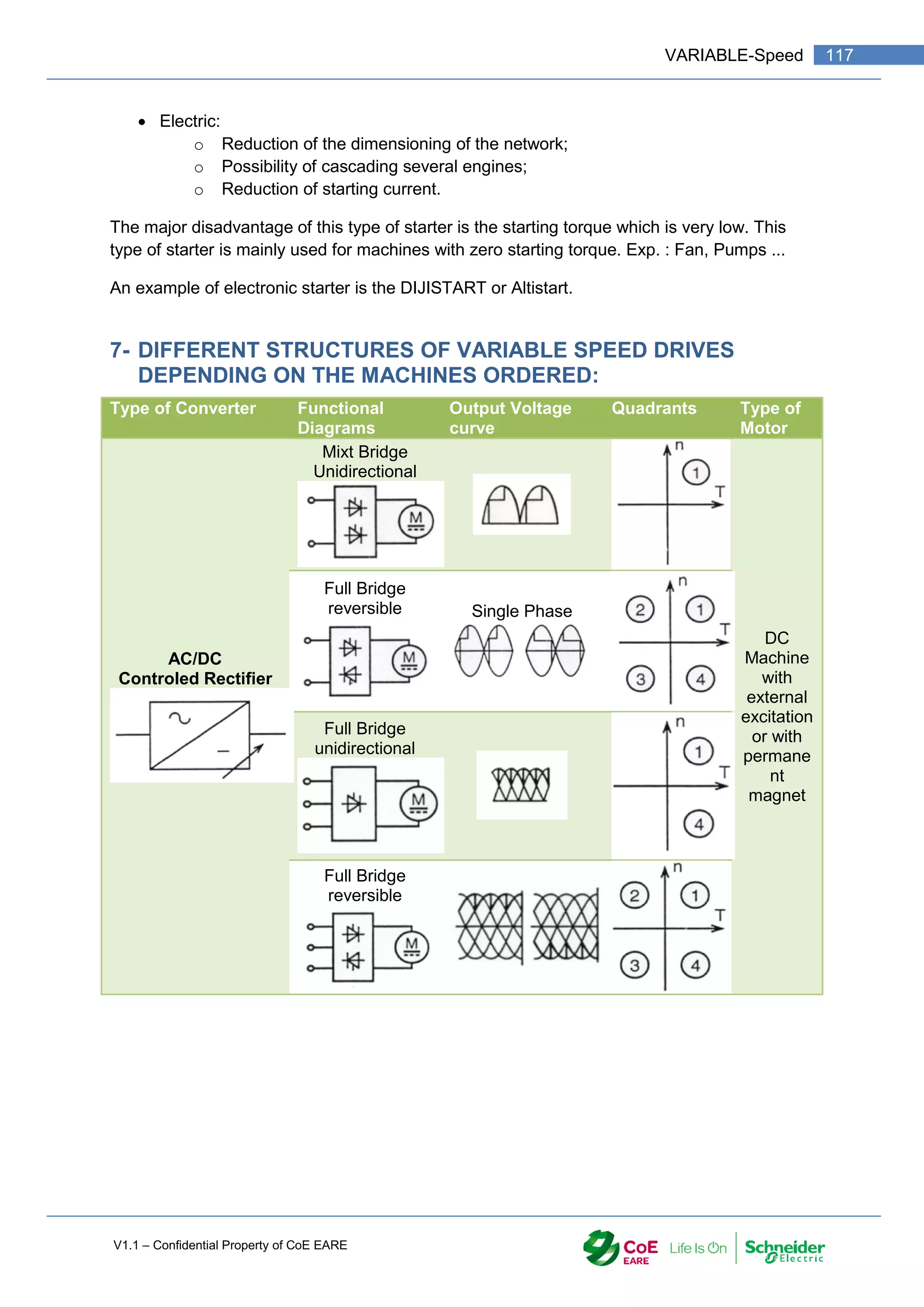

Basic Industrial wiring]

Eric Dupont](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-1-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

2 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-2-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

2 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-4-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

4 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Safety & Security

In this section the topics will be the effect of the electricity on the human Body, the way to

prevent electric shock, the equipment used to protect people.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-6-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

6 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

1- PREAMBLE:

As electric current is conducted through a material, any opposition to that flow of electrons

(resistance) results in a dissipation of energy, usually in the form of heat. This is the most

basic and easy-to-understand effect of electricity on living tissue: current makes it heat up. If

the amount of heat generated is sufficient, the tissue may be burnt. The effect is

physiologically the same as damage caused by an open flame or other high-temperature

source of heat, except that electricity has the ability to burn tissue well beneath the skin of a

victim, even burning internal organs.

Another effect of electric current on the body, perhaps the most significant in terms of

hazard, regards the nervous system. By "nervous system" I mean the network of special cells

in the body called "nerve cells" or "neurons" which process and conduct the multitude of

signals responsible for regulation of many body functions. The brain, spinal cord, and

sensory/motor organs in the body function together to allow it to sense, move, respond, think,

and remember.

2- DEFINITIONS

Internal impedance of the human body (Z1): Impedance between two electrodes in

contact with two parts of the human body, after removing the skin from under the

electrodes.

Impedance of the skin (Zp): Impedance between an electrode on the skin and the

conductive tissues underneath.

Total impedance of the human body (ZT): Vectorial sum of the internal impedance

and the impedances of the skin.

Initial resistance of the human body (Ri): Resistance limiting the peak value of the

current at the moment when the touch voltage occurs.

Threshold of perception: The minimum value of current which causes any

sensation for the person through which it is flowing.

Threshold of let-go: The maximum value of current at which a person holding

electrodes can let go of the electrodes.

Threshold of ventricular fibrillation: The minimum value of current which causes

ventricular fibrillation.

Heart current factor: The heart current factor relates the electric field strength in the

heart for a given current path to the electric field strength in the heart for a current of

equal magnitude flowing from left hand to feet. Note. - In the heart, the current density

is proportional to the electric field strength.

3- MAIN CAUSES OF ELECTRIC CHOCKS

3.1- MAIN CAUSES ARE:

- Operating mode inappropriate or dangerous (31%),

- Lack of awareness of risks (30%),

- Incomplete application procedures (15%),

- Inadequate training (12%),

- The state of the material (12%),](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-8-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

8 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

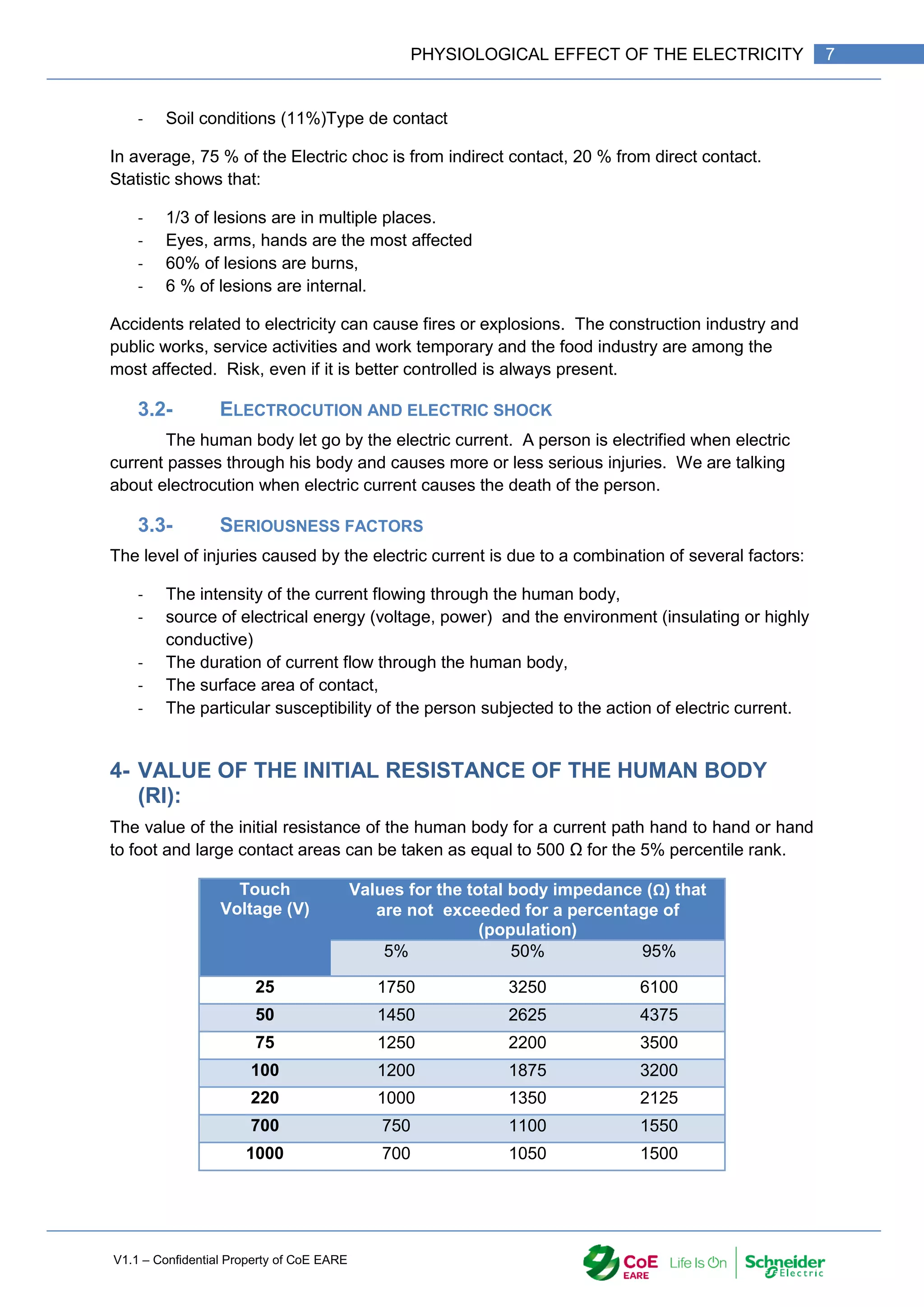

The internal impedance of the human body is a function of the current path.

5- CURRENT THROUGH THE BODY AND EFFECTS

The effect of the current in a body can take several forms.

- Thermic effect – Burns (can be done with 10 mA if the contact takes few minutes.

- Tetanizing Effects – When an AC current is going through the body, muscles are

contracted.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-10-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

10 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-12-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

12 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

conductive-part see. IEC 61140 standard has renamed “protection against indirect contact”

with the term “fault protection”. The former name is at least kept for information.

7- FIRST AID

The danger from an electrical shock depends on the type of current, how high the voltage is,

how the current travelled through the body, the person's overall health and how quickly the

person is treated.

Call your local emergency number immediately if any of these signs or symptoms

occurs:

Cardiac arrest

Heart rhythm problems (arrhythmias)

Respiratory failure

Muscle pain and contractions

Burns

Seizures

Numbness and tingling

Unconsciousness

While waiting for medical help, follow these steps:

Look first. Don't touch. The person may still be in contact with the electrical source.

Touching the person may pass the current through you.

Turn off the source of electricity, if possible. If not, move the source away from you

and the person, using a dry, no-conducting object made of cardboard, plastic or

wood.

Check for signs of circulation (breathing, coughing or movement). If absent, begin

cardiopulmonary resuscitation (CPR) immediately.

Prevent shock. Lay the person down and, if possible, position the head slightly lower

than the trunk with the legs elevated.

After coming into contact with electricity, the person should see a doctor to check for internal

injuries, even if he or she has no obvious signs or symptoms.

Caution

Don't touch the person with your bare hands if he or she is still in contact with the

electrical current.

Don't get near high-voltage wires until the power is turned off. Stay at least 20 feet

away — farther if wires are jumping and sparking.

Don't move a person with an electrical injury unless the person is in immediate

danger.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-14-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

14 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

1- INTRODUCTION

The security in electrical work is one of the most important part of the work. By nature

electricity is dangerous and all actions have to be taken to prevent electric hazards and

protect people against Direct and Indirect chocks.

2- PREVENT DIRECT CONTACTS:

When it is not possible to shut down the power or lock a switch

disconnector, live accessible part to workers must be ensured

by:

- Remoteness,

- Obstacles

- Insulation.

2.1- REMOTENESS

Remoteness is to provide enough distance between live parts and worker that a contact

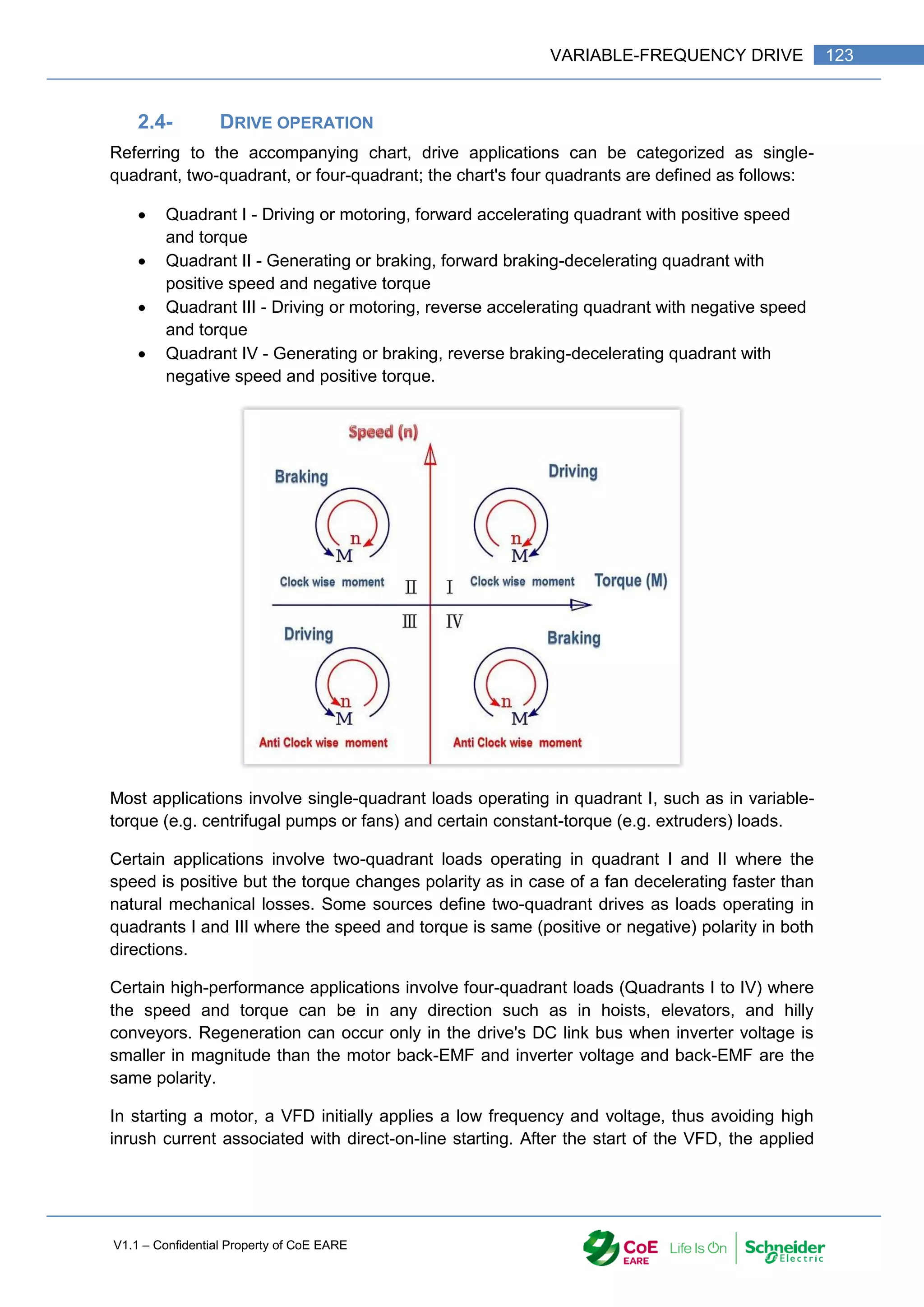

won’t be possible with conducting object. (metallic pipe, …)

2.2- OBSTACLES

The insulation between people and live part is

provided by putting in place obstacles when the

remoteness is not possible. The obstacles can be

cabinets, boxes … protecting people against direct

contact.

2.3- INSULATION

Insulation consist in cover live part with insulated

material such as insulated mat … This is required

when the remoteness and obstacle procedure can't be

put in place.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-16-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

16 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

4.1- CLASS 0

These appliances have no protective-earth connection and feature only a single level of

insulation and were intended for use in dry areas. A single fault could cause an electric shock

or other dangerous occurrence. Theses appliances are forbidden.

4.2- CLASS 1

These appliances must have their chassis connected to electrical earth (ground)

by a separate earth conductor (coloured green - green/yellow in most countries).

The earth connection is achieved with a 3-conductor mains cable, typically ending

with 3-prong AC connector which plugs into a corresponding AC outlet. The basic

requirement is that no single failure can result in dangerous voltage becoming exposed so

that it might cause an electric shock and that if a fault occurs the supply will be removed

automatically.

A fault in the appliance which causes a live conductor to contact the casing will cause a

current to flow in the earth conductor. If large enough, this current will trip an over-current

device (fuse or circuit breaker (CB)) and disconnect the supply.

4.3- CLASS 2

A Class II or double insulated electrical appliance is one which has been designed

in such a way that it does not require a safety connection to electrical earth

(ground). The basic requirement is that no single failure can result in dangerous

voltage becoming exposed so that it might cause an electric shock and that this is

achieved without relying on an earthed metal casing. This is usually achieved at least in part

by having two layers of insulating material surrounding live parts or by using reinforced

insulation.

4.4- CLASS 3

A Class III appliance is designed to be supplied from a separated/safety extra-low

voltage (SELV) power source. The voltage from a SELV supply is low enough that

under normal conditions a person can safely come into contact with it without risk of

electrical shock. For medical devices, compliance with Class III is not considered sufficient

protection, and further more-stringent regulations apply to such equipment.

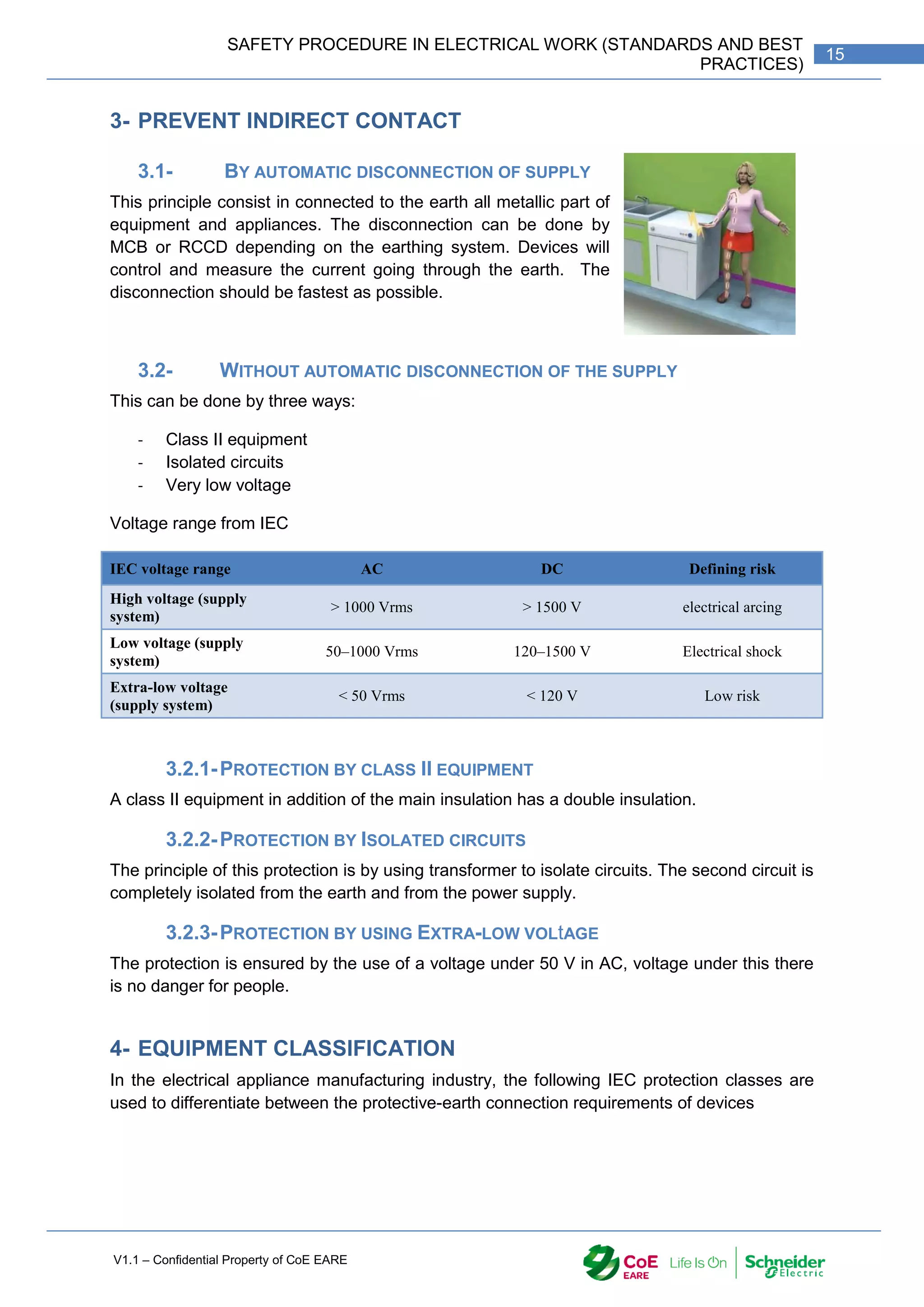

5- IP CODE

The IP Code, International Protection Marking (IEC 60529), classifies and rates the degree of

protection provided against the intrusion (including body parts such as hands and fingers),

dust, accidental contact, and water by mechanical casings and electrical enclosures.

The standard aims to provide users more detailed information than vague marketing terms

such as waterproof. The digits (characteristic numerals) indicate conformity with the

conditions summarized in the tables below. Where there is no protection rating with regard to

one of the criteria, the digit is replaced with the letter X.

With the IP rating IP 54

- “5” describes the level of protection from solid objects](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-18-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

18 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

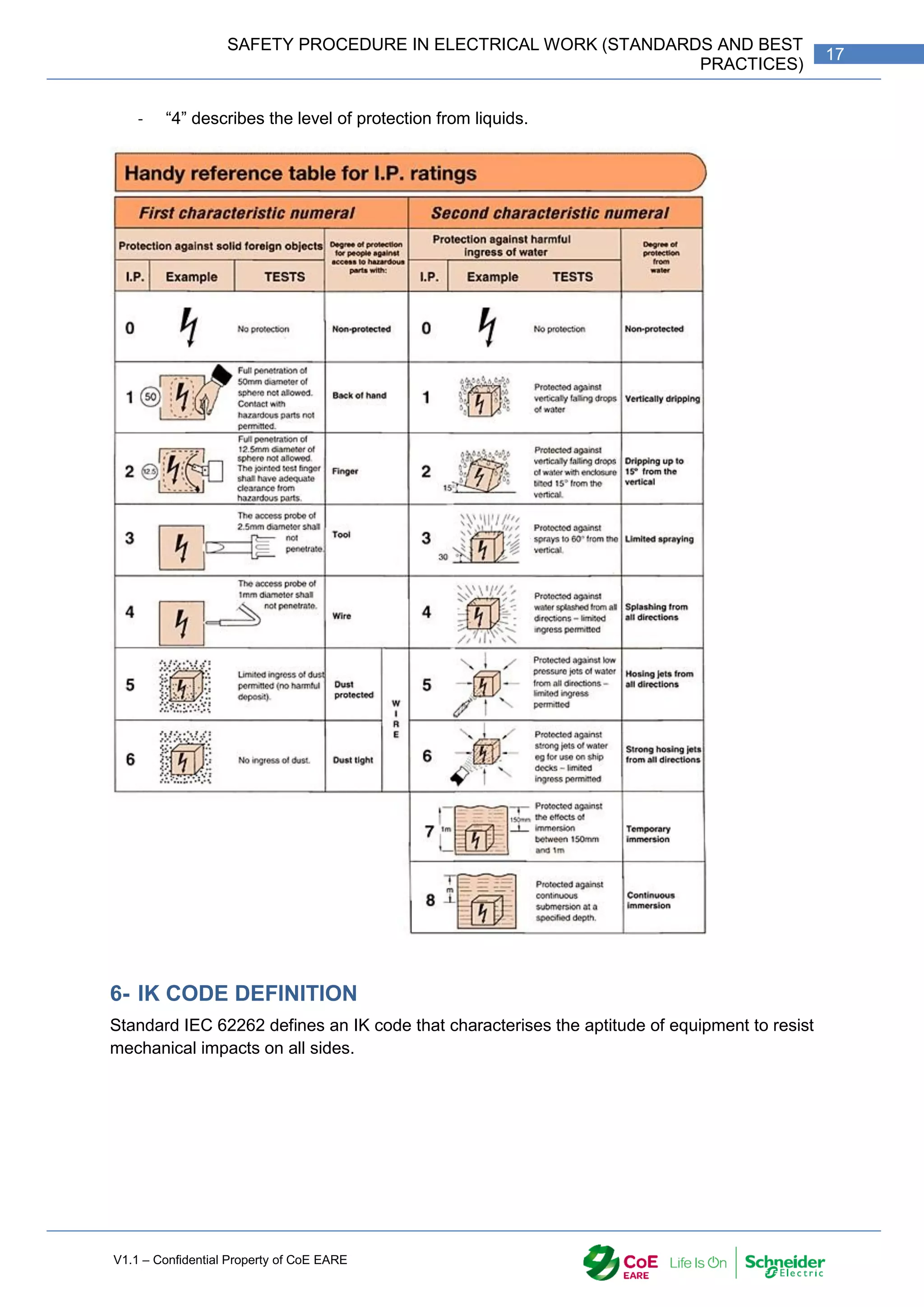

7- OVERVOLTAGE CATEGORIES

Measurement category is classification of live electric circuits is used in measurement and

testing of installations and equipment, usually in the relation within a building (residential or

industrial).

The categories take into account the total continuous energy available at the given point of

circuit, and the occurrence of impulse voltages. The energy can be limited by circuit breakers

or fuses, and the impulse voltages by the nominal level of voltage

There are four categories designated by a mark such as “CAT III, 150 V" or "CAT IV, 1000

V".

CAT I is applicable to instruments and equipment, which are not intended to be

connected to the mains supply. Because the available energy is very limited, this

category is normally not marked on the equipment.

Examples: low voltage electronic circuits, load circuits of bench power supplies, etc.

CAT II defines circuits which are intended for direct connection into mains sockets or

similar points. The energy in such installations should be limited to below 100 A

continuously (or below 500 A for voltages not exceeding 150 V). The maximum

available continuous power must be limited (for instance by a circuit breaker) to not

more than 22 000 VA.

Example: a device connected to a 240 V mains socket with 13 A fuse (energy limited to 3100

VA)](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-20-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

20 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Rated Voltage IEC 61010-1 2nd Edition

CAT IV CAT III CAT II

150V 4,000V 2,500V 1,500V

300V 6,000V 4,000V 2,500V

600V 8,000V 6,000V 4,000V

1,000V 12,000V 8,000V 6,000V

Resistance 2 ohms 2 ohms 12 ohms

8- SECURITY EQUIPMENT

“It is the duty of all persons who may be concerned with the installation, operation and

maintenance of electric lines and apparatus to make themselves thoroughly conversant with

the regulations and safety rules governing the work they may have to undertake on these

lines and apparatus.” (IS.5216.1.1.1982 § 2.1)

8.1- PERSONAL PROTECTIVE EQUIPMENT (PPE)

Personal protective equipment (PPE) is all equipment needed to

protect an electrician against electric shock to protect himself. Each

worker undertakes the responsibility of its protective equipment and

must check the condition on each equipment before use. Any

damaged equipment should be not used and be replaced.

The PPE are:

safety glasses

face shields

hard insulated hats

safety isolated shoes

insulating (rubber) gloves with leather

protectors

insulating sleeves

flame-resistant (FR) clothing](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-22-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

22 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

9- MEASURING DEVICES

Make an electrical measurement is one of the situations where the risk of electric shock is

important. The electrician should be sure that the measuring device is in good condition and

matches some rules.

The measuring device should:

Have an insulating case

Be Class II

Have an IP2X

Have the right measurement category.

All accessories have to match those rules.

10- PERMIT-TO-WORK SYSTEM

All work on major electrical installations shall be carried out under permit-to-work system

which is now well established, unless standing instructions are issued by the competent

authority to follow other procedures except in extenuating circumstances (saving life…) in

this case the action taken shall be reported to the person-in-charge. The permit-to-work

certificate from the person-in-charge of operation to the person-in-charge of the men

selected to carry out any particular work ensures that the portion of the installation where the

work is to be carried out is rendered -dead and safe for working. All work shall be carried out

under the personal supervision of a competent person. If more than one department is

working on the same apparatus, a permit-to- work should be issued to the person-in-charge

of each department.

No work shall be commenced on live mains unless it is specifically intended to be so done by

specially trained staff. In such cases all possible precautions shall be taken to ensure the

safety of the staff engaged for such work, and also of others who may be directly or indirectly

connected with the work. Such work shall only be carried out with proper equipment provided

for the purpose and, after taking necessary precautions, by specially trained and experienced

persons who are aware of the danger that exists when working on or near live mains or

apparatus.

The permit is to be prepared in duplicate by the person-in-charge of operation on the

basis of message, duly logged, from the person-m-charge of the work.

The original permit will be issued to the person-in-charge of work and the duplicate

will be retained in the permit book. For further allocation of work by the permit

receiving officer, tokens may be issued to the workers authorizing them individually to

carry out the prescribed work.

On completion of the work, the original shall be returned to the issuing officer duly

discharged for cancellation.

11- EXAMPLE OF PERMIT-TO-WORK IN APPENDIX

Appendix 1](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-24-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

24 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

13- ELECTRICAL AUTHORIZATION

13.1- PREAMBLE:

The IEC 61010 defines the roles and duties to everyone involved in the electrical work. This

standard has been made to protect worker against electrical hazards.

13.2- PRINCIPLE:

People (electrician or not) give an authorization to do work related to electricity. This

authorization is given for particular task and certifies that the owner of the authorization

knows about risks and danger of electricity.

This authorization is required for:

Enter in electrical room.

Do electrical work. (Measurement, maintenance …)

Manage electrical work

Shut down power and lock switch-disconnector.

Do electrical test

Be a safety watcher

The employer is responsible to give the “Electrical Authorization”. He has to check that the

employee has the required knowledge on:

Present electric hazards;

Taking care of its own security and the security to people under its supervision;

The action to do in case of accident

The ability of the employee to do the work and tasks.

13.3- THE ELECTRICAL AUTHORIZATION

The Electrical Authorization is delivered by the employer to its selected employees under

its responsibility and it is only valid for the time of working to the company.

The Electrical Authorization is a document filed in by the employer and signed by the

employer and the employee.

13.4- WORK ZONE AND VICINITY

(As defined in the section 13.4-)

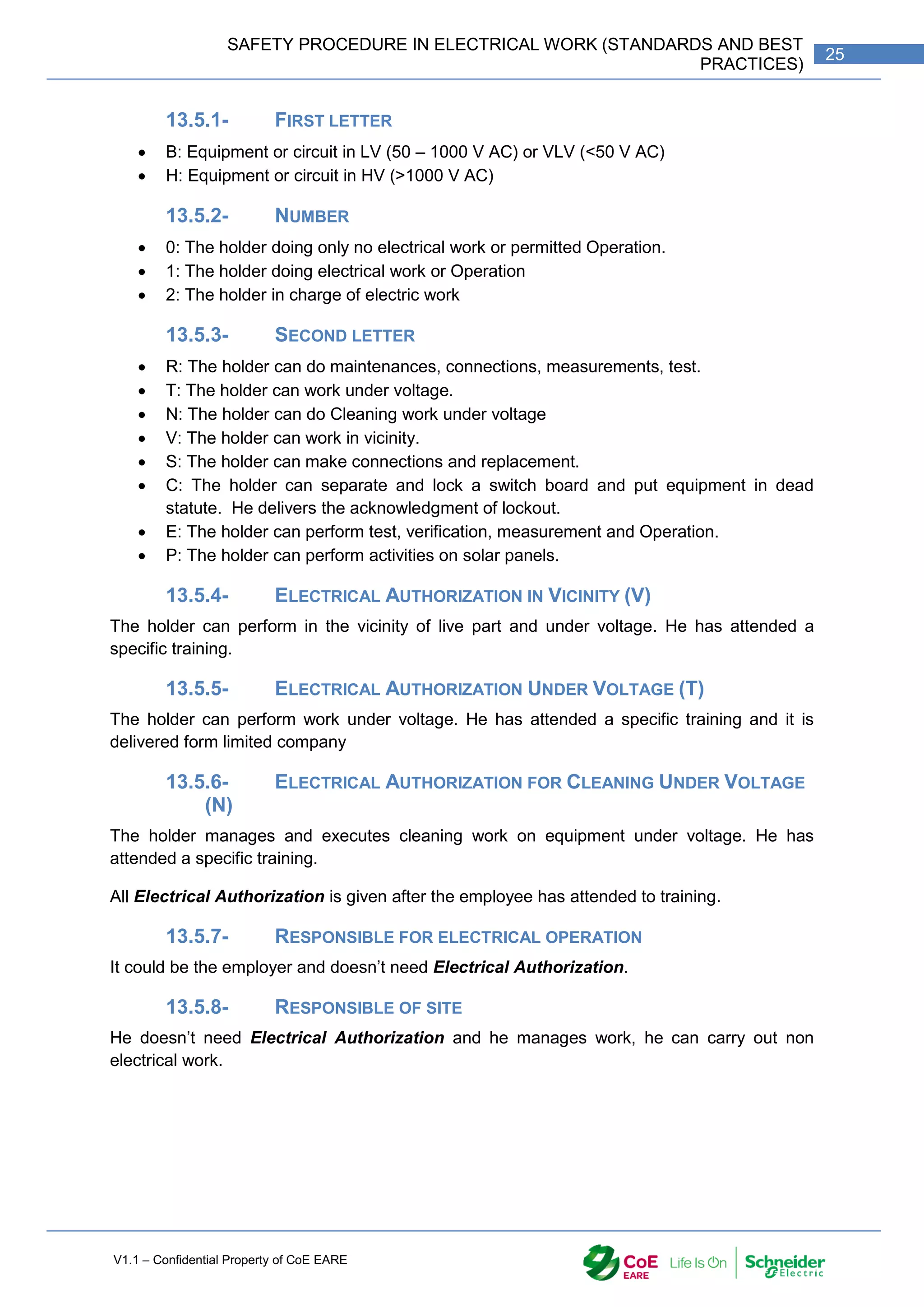

13.5- SYMBOLS AND CLASSIFICATION

The Electrical Authorization is defined by a letter, a number and a letter.

B x V

Who? What?

Where?

Second letter:

Type of work.

Number:

Function.

First letter:

Voltage level](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-26-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

26 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

13.6- WORK DEFINITION

13.6.1- NON ELECTRICIAN B0 / H0 OR H0V

The holder can access to the electrical room without supervision and execute or manage no

electrical tasks such as painting, cleaning…

13.6.2- EMPLOYEE IN CHARGE OF THE CLEANING UNDER VOLTAGE (N)

Employee managing or doing cleaning work under voltage.

13.6.3- ELECTRICIAN EXECUTANT B1 / H1 OR B1V / H1V

Employee that works as electrician and who is following instruction. He is aware of its

security.

He can access to the electric room without authorization.

He can perform work and Operation near live parts.

He can perform measurement with clampmeter

He is working in team under the supervision of the Responsible for electrical work

(B or H2) or Responsible of Intervention (BR)

The holder of B1V or H1V can work in vicinity.

13.6.4- RESPONSIBLE IN CHARGE OF THE ELECTRIC WORK (B2 / H2 –

B2V / H2V)

The holder of the B2 or H2 manages the work and the tasks and takes all actions to ensure

its security and the security of people under its supervision.

He is responsible of the execution of its security order.

It can receive an acknowledgment of lockout and sign it

The older is also 0 and 1

The holder of B2V or H2V can work in vicinity.

13.6.5- RESPONSIBLE IN CHARGE OF THE LOCKOUT (BC / HC)

The holder of a BC is performing the Power disconnection of equipment by opening a switch

disconnector and locks it with proper lock. He takes all action to guaranty the safety and

security.

He has to have the agreement from the Responsible of site

He executes the four steps of the lockout or only the two first. In this case, the last

two steps are done by the Responsible in charge of the electric work.

The BC or HC Electrical Authorisation doesn’t allow the holder to supervise the

security.

13.7- INTERVENTIONS

13.7.1- RESPONSIBLE IN CHARGE OF INTERVENTION (BR)

The holder can be assisted by an Electrician executant on equipment which has previously

been lockout.

The Responsible in charge of Intervention (BR) is designated.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-28-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

28 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

It should mention:

Name, surname of the employee

Function of the employee

Employer

Level (s) of Electrical Authorization

date

13.10- THE PADLOCKING

This the duty of the holder of BC / HC Electrical Authorization

He does or supervises the lockout

He is responsible of the disconnection of the equipment from the power supply and

the lock of the switch disconnector.

He his establishing the acknowledgment of lockout.

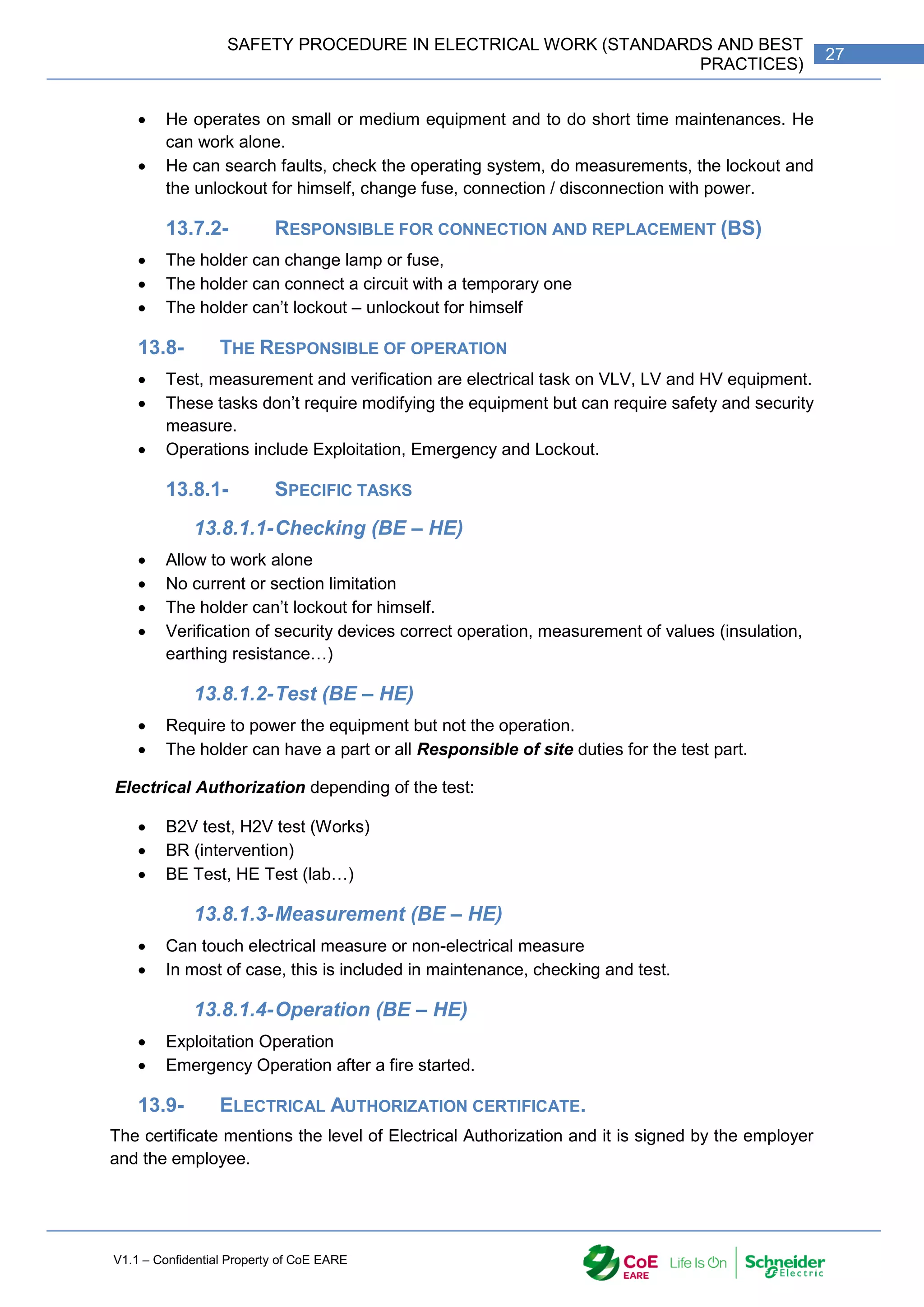

13.10.1- THE FIVE STEPS OF PADLOCKING

13.10.1.1- First step: Disconnection

Acknowledgment

should be signed

2- Lock

1-

Disconnect

3- Identify the

equipment 4- Doing the

Voltage checking

and the earthing

Switch disconnector

Sockets

Withdraw fuse

Plug devices

Control, protesting devices](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-30-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

30 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

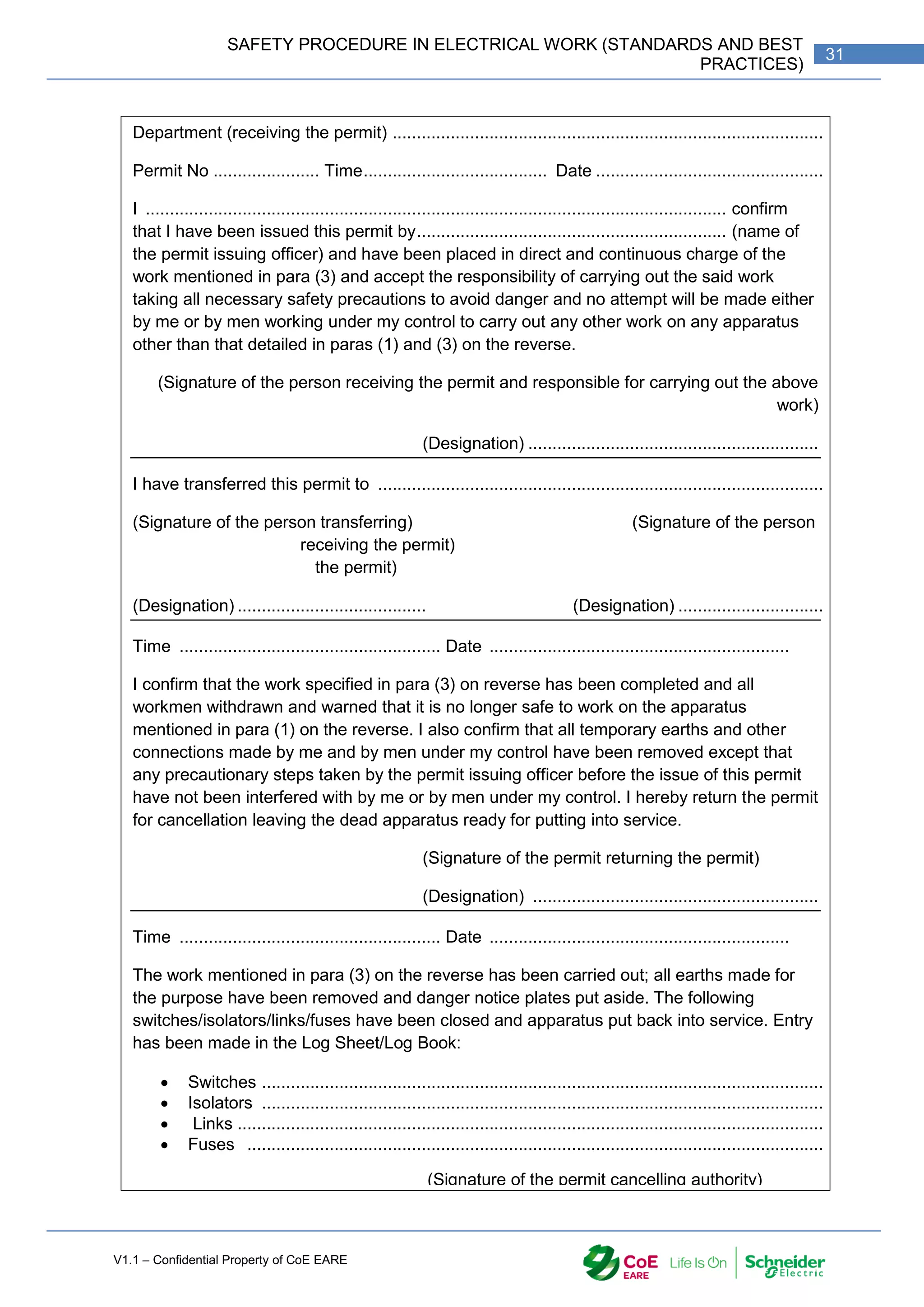

14- APPENDIX

Appendix 1 : Permit-to-work

MODEL FORM OF PERMIT-TO-WORK

Name of the Organization ...................................................................................................

Department (issuing the permit) ............................................................................................

Permit No. .................... Time .....................................Date.................................................

1. I ....................................................................................... certify that the following

apparatus has been made dead, is isolated from all live conductors and has been

connected to earth and the work mentioned in para (3) can now be carried out in

accordance with the safety rules and regulations :

2. For the purpose of making the above apparatus dead, the following

switches/isolators/links/fuses have been opened and the section so isolated has been

earthed at each isolation point and danger notice plates tied thereon:

Switches ....................................................................................................................

Isolators .....................................................................................................................

Links .........................................................................................................................

Fuses .......................................................................................................................

3. Work to be carried out (testing work, if any, to be specifically mentioned):

..............................................................................................................................................

..............................................................................................................................................

..............................................................................................................................................

4. I have also recorded the above operations in the Log Sheet/Log Book including the

instructions for the person who may relieve me.

This permit is now being issued to ................................................................(name of the

person to whom the permit is being issued) for carrying out the work mentioned in para (3).

(Signature of the permit issuing authority)

(Designation) .........................................................](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-32-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

34 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

DEVICES IN INDUSTRIAL WIRING](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-36-2048.jpg)

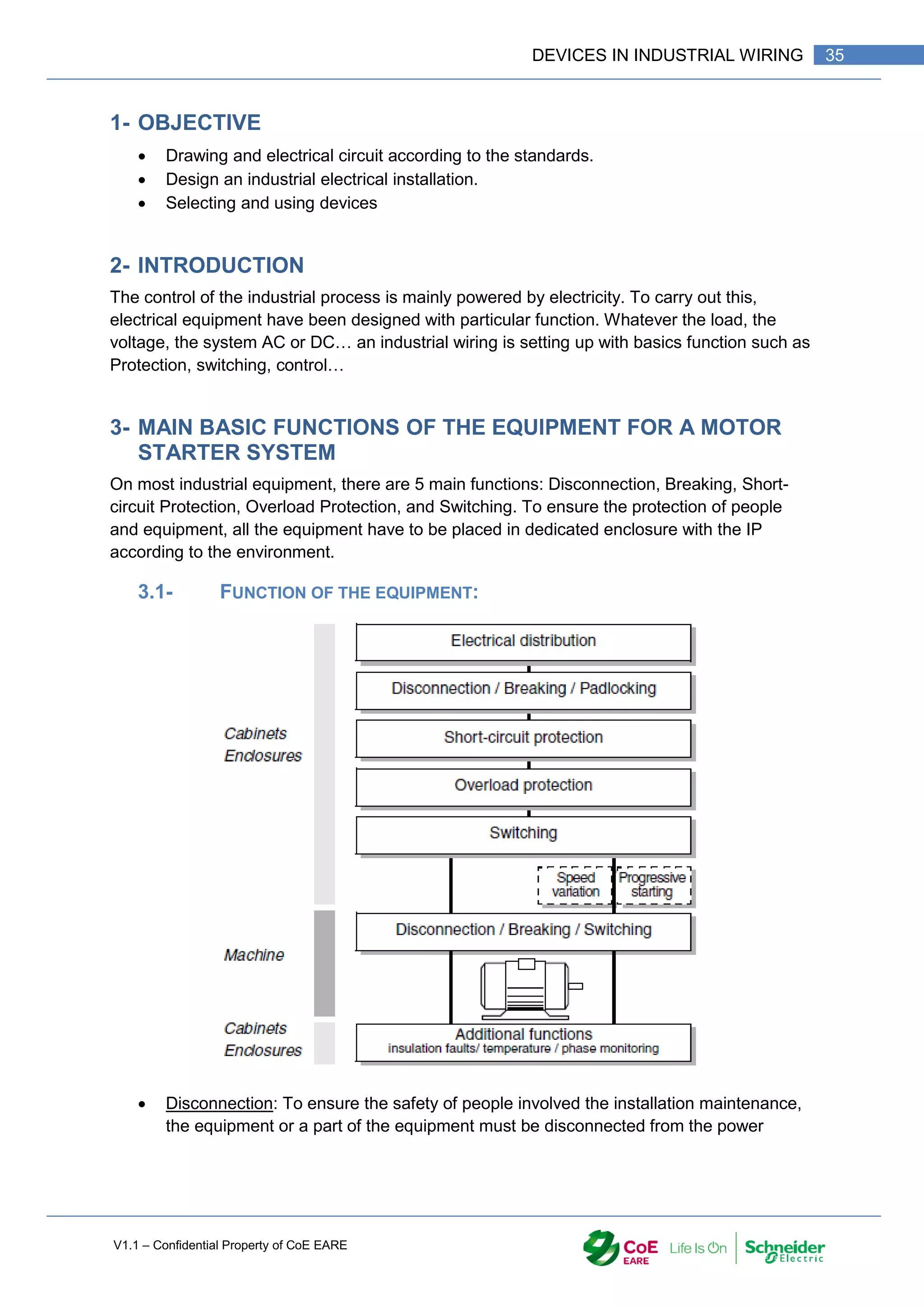

![V1.1 – Confidential Property of CoE EARE

36 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

supply. A padlocking mechanism may be added to the disconnection device to

procure more protection.

Breaking: The breaking function is mandatory to be able to break the power supply

(on full load) in case of emergency.

Short-circuit Protection: To avoid accidental damages on the equipment, disturbance

on the network (Unbalance), risk for the people security, the short circuit must be

detected and the faulty circuit have to be quickly opened.

Overload Protection: Mechanical overloads and supply network faults are the most

common causes of the overload withstood by motors. This results in a considerable

increase in current drawn up by the motor, resulting in excessive temperature rise

and greatly reducing motor lifetime. It could even lead to destruction of the motor.

Motor overload must therefore be detected.

Switching: Its function is to make and break the motor supply circuit.

4- DEVICES OR EQUIPMENT USED FOR THESE FUNCTIONS

Sizing and implementation of this equipment must comply with standards rules. A particular

attention is done on the discrimination and cascading of the protection and breaking.

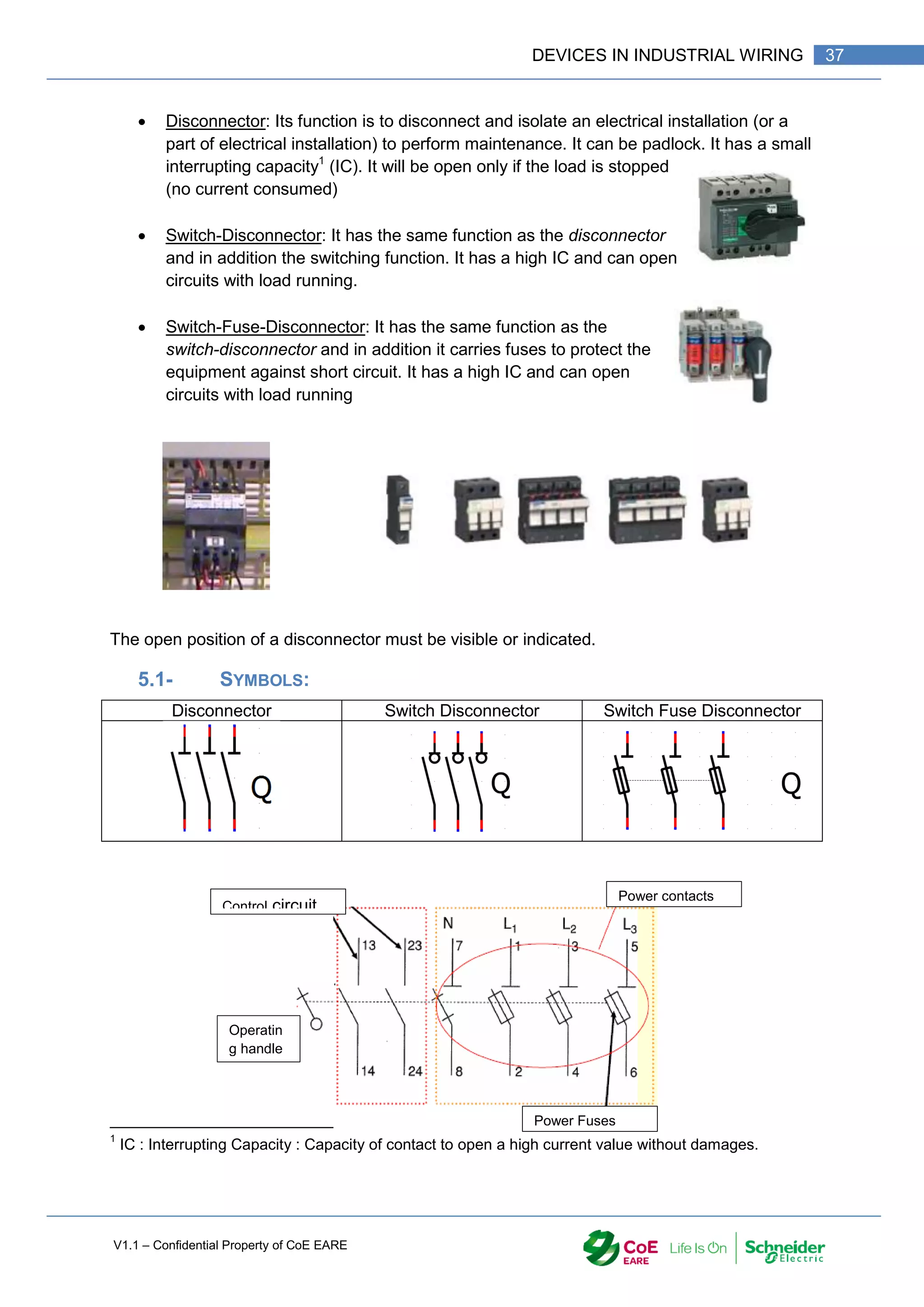

5- DISCONNECTOR / SWITCH DISCONNECTOR / SWITCH FUSE

DISCONNECTOR

The use of disconnector is mandatory in industrial wiring. It is used

to isolate the electrical panel from the power supply.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-38-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

38 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

5.2- AM OR GG FUSES:

gG Fuses protect against short circuit in an electrical installation, mainly for resistive

load.

aM Fuses protect against short circuit in electrical installation with Inductive load such

as Induction engine or transformer.

5.3- TYPE OF FUSE:

Depending on the local standards, fuses can have different design.

NFC/Din Fuses type BS Fuses CC Fuses type J Fuse type

5.4- SELECTION CRITERIA

5.5- EXAMPLE

Find the reference of Switch Fuse Disconnector and the fuses to supply a Pa=10 kW

induction motor (cos 𝜌 = 0.851,) with a 3* 400V network and

𝑃𝑎 = √3 ∗ 𝑈 ∗ 𝐼 ∗ cos 𝜌

𝐼 =

𝑃𝑎

√3 ∗ 𝑈 ∗ cos𝜌

=

10 000

√3 ∗ 400 ∗ 0.851

= 16.98𝐴

• 1P + N: Phase + Neutral

• 2P: Two Phases

• 3P: Triphase

• 3P+N: Triphase + Neutral

No of

Poles

• Rated Voltage Ue; Maximum voltage between 2 poles.

Rated

Voltage

• Maximun curent that the device can support without any damages

Rating

• gG or aM depending of the load

Fuses Type

• 1 or 2 control contact

No of control

contact

• Type of Operatin Handle

• Clamping system

• Padlocking system

Accesories

Switch Fuse Disconnector

reference](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-40-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

40 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

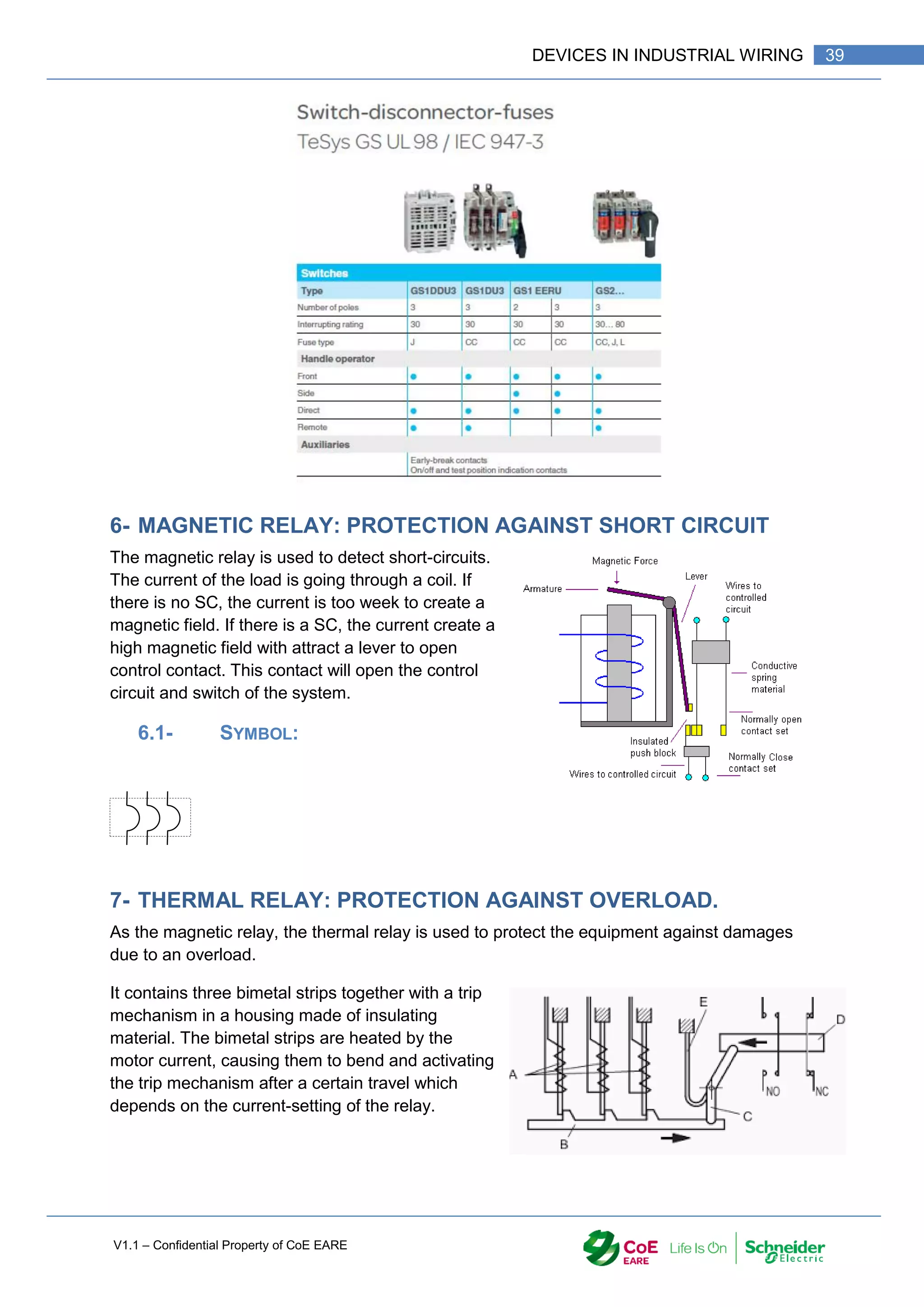

The release mechanism actuates an auxiliary switch that breaks the coil circuit of the motor

contactor (Figure 1). A switching position indicator signals the condition “tripped”.

A = Indirectly heated bimetal strips

B = Trip slide

C = Trip lever

D = Contact lever

E = Compensation bimetal strip

7.1- SYMBOL:

Power circuit: Control circuit or

7.2- CLASS OF THE THERMAL RELAY:

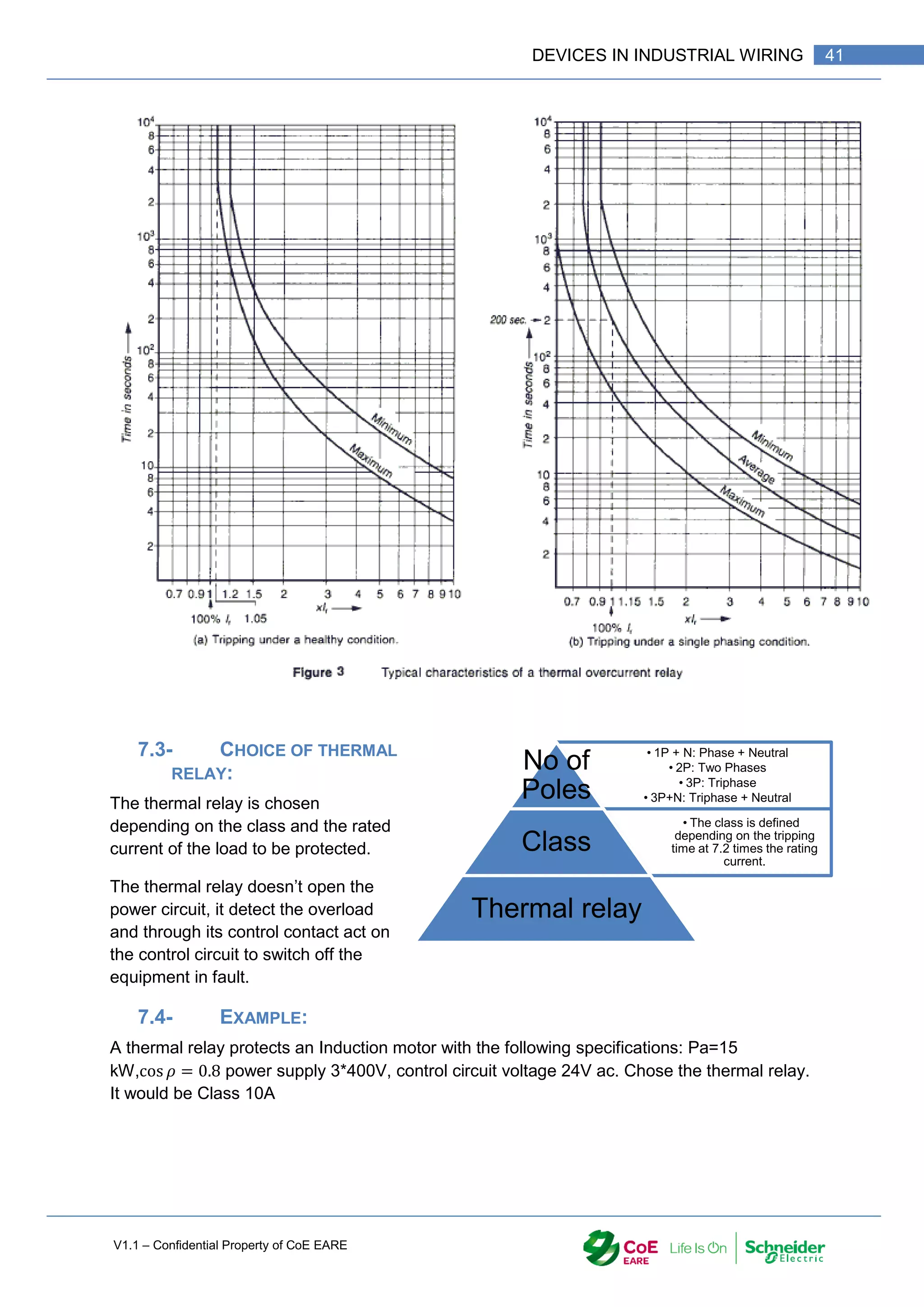

The class of thermal relay define its behaviour in case of overload and the tripping time.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-42-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

42 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

𝐼 =

𝑃𝑎

√3 ∗ 𝑈 ∗ cos 𝜌

=

15 000

√3 ∗ 400 ∗ 0.8

= 27𝐴

Thermal relay: LRD 32, setting at 27 A

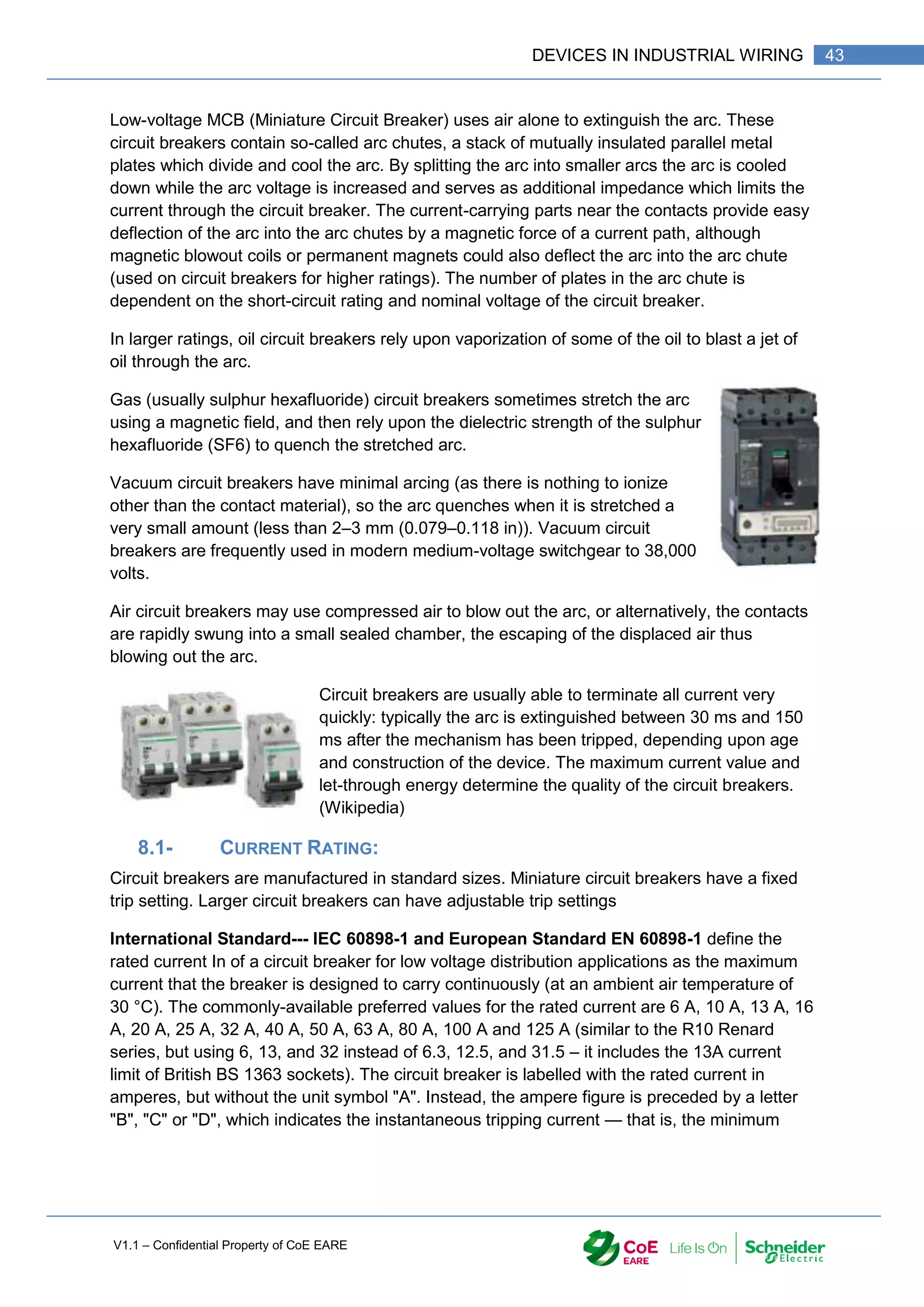

8- CIRCUIT BREAKER

A circuit breaker is an automatically operated electrical switch designed to protect an

electrical circuit from damage caused by Overcurrent/overload or short circuit. Its basic

function is to interrupt current flow after Protective relays detect faults condition. Unlike a

fuse, which operates once and then must be replaced, a circuit breaker can be reset (either

manually or automatically) to resume normal operation. Circuit breakers are made in varying

sizes, from small devices that protect an individual household appliance up to large

switchgear designed to protect high voltage circuits feeding an entire city. (Wikipedia)

As per the nature of the current, especially in case of short circuit, the circuit breaker has the

ability to cut electric arc. For this, different methods are used:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-44-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

44 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

value of current that causes the circuit breaker to trip without intentional time delay (i.e., in

less than 100 ms), expressed in terms of In:

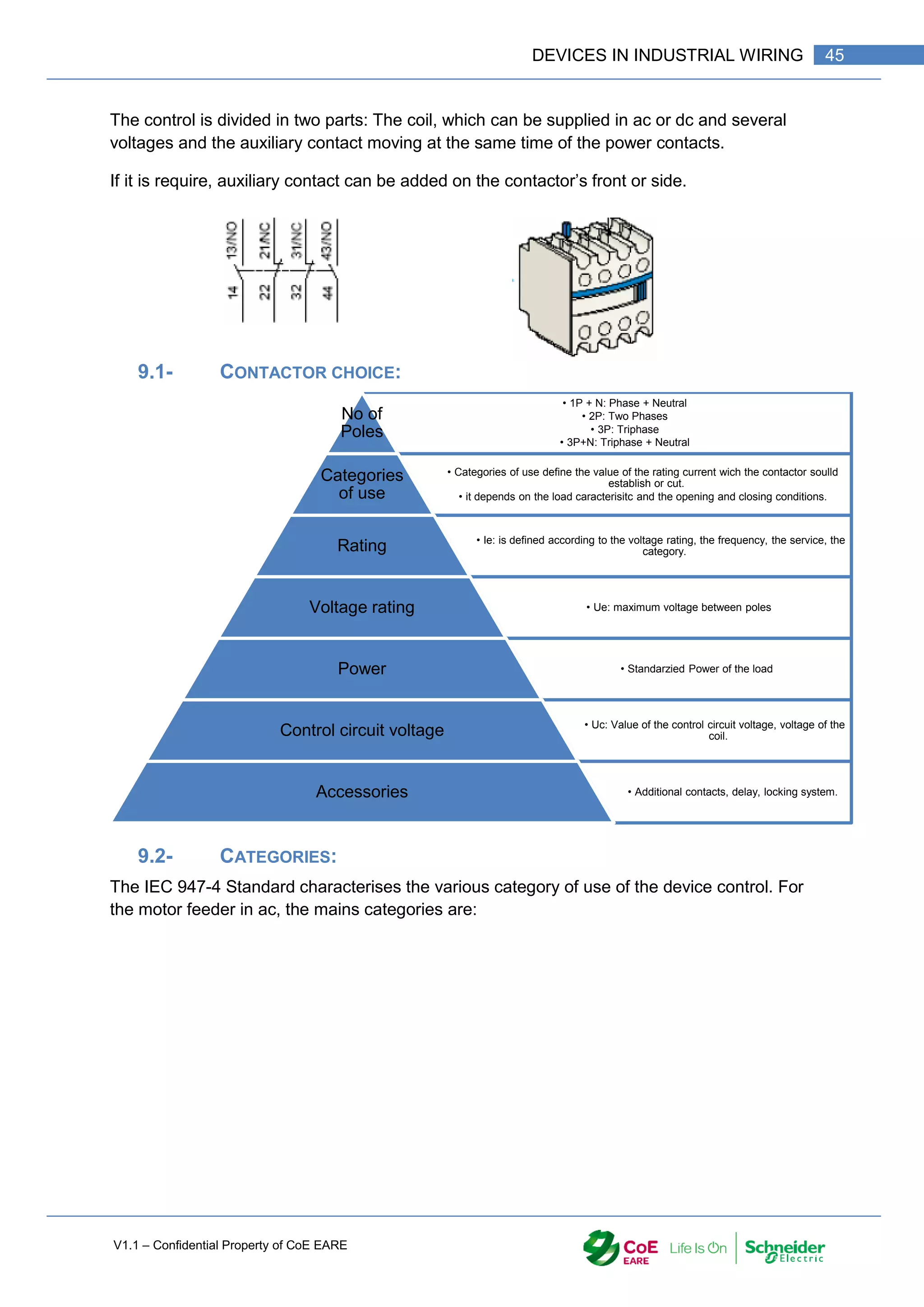

9- THE CONTACTOR

A contactor is an electrically controlled switch used for switching an electrical power circuit,

similar to a relay except with higher current ratings. A contactor is controlled by a circuit

which has a much lower power level than the switched circuit.

A contactor is composed on two parts: Power and control part.

The power part is composed of contacts (3 / 4) with high Interruption capacity. All contact are

closing or Opening at the same time. They are moved by the coil of the control circuit. When

this one is supplied, it attracts the moving part and the power contacts are closing. In

contrary, when the coil is not powered, a spring move back the moving part and the power

contacts are opening. A contactor is a switch controlled by a coil.

The power part can have 1, 2, 3 or 4 contacts. They can be Normally Open or Normally

Closed. The rating depends on the load current.

Power part

Control part Auxiliary contacts](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-46-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

46 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

9.3- SYMBOLS:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-48-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

48 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

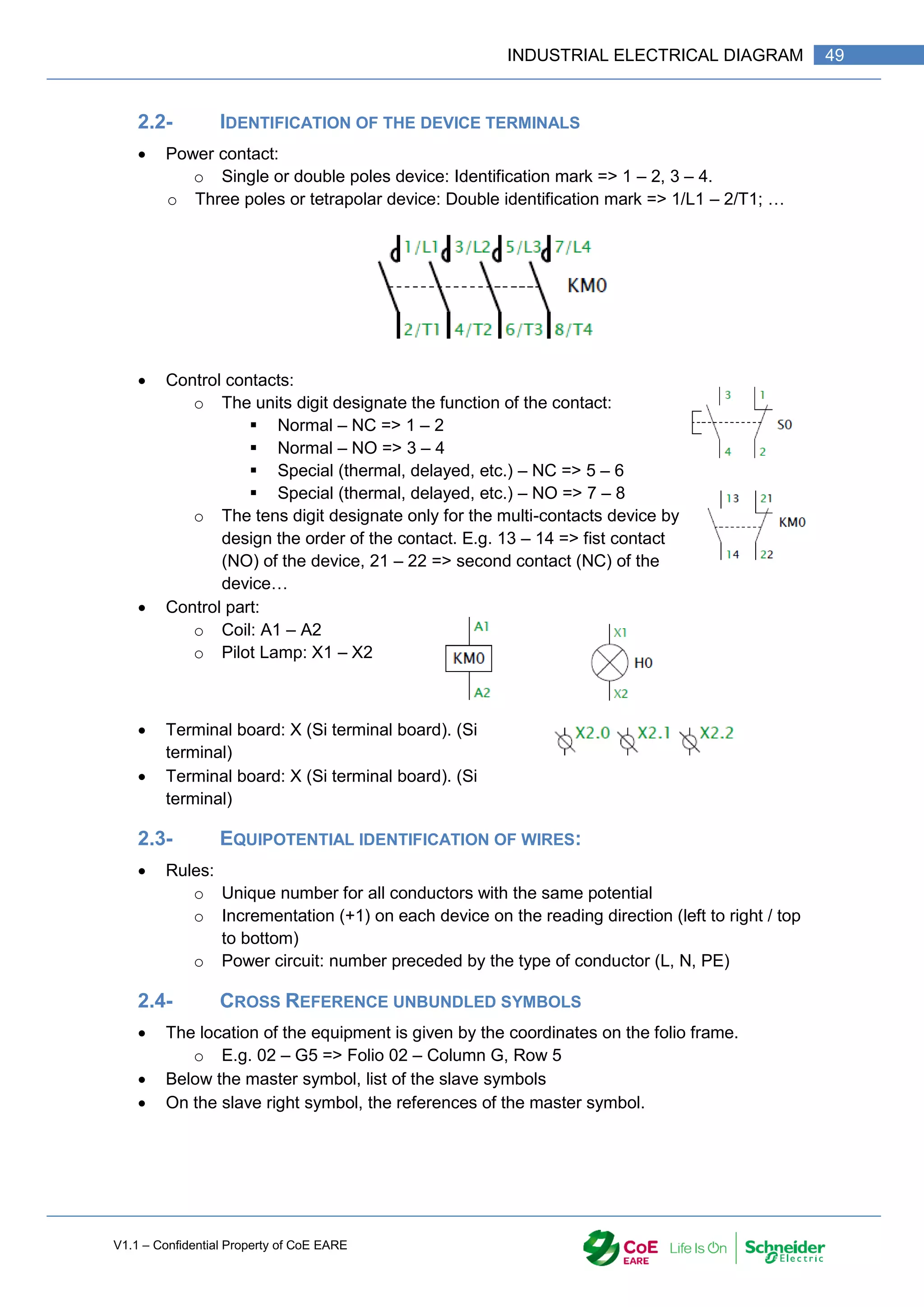

1- INTRODUCTION

Electrical diagram is the part of the industrial system. It is one of the first steps in the design

process of an industrial system or machine. It is not an architectural representation (in

industrial), it shows the devices used in the system and the connections between them.

Symbols used have been designed and standardized to be readable by

every technician.

2- SYMBOLS USED

There are plenty of symbols representing an electrical device. To be able

to be read by every technician, symbols were standardized and an

international standard created: The IEC IEC60617 – part 7. Local

standards have been designed by following the IEC one.

The IEC 60617 is available on annexe files. (IEC60617 Symbols.pdf)

The target of the electrical diagram is the readability of the operation of

the different circuits (Control, Power … circuits)

2.1- SYMBOLIZATION OF DEVICES

Main contacts: Power circuit

o From 0 (control device) to 4 power contacts.

o Always represented together, they are drawn in solid line

Auxiliary contacts: Control circuit

o From 0 to 5 contacts, more with the use of add

o Ungrouped, drawn in fine line

o 2 types: Normally Open (NO), Normally Closed (NC)

o Mechanically linked to the control part they indicate the state of the device. By

this, the state of a device can be used in a control circuit.

Control part (control of the contacts) Operated by Pushing

o Manual: drawn on the contact’s left side.

o Electric (coil) load of the control circuit

Mechanical link:

o Partially drawn if it disturbs the reading of the electrical diagram.

Power part

Control part

Mechanical link

Auxiliary contacts](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-50-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

50 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-52-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

52 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

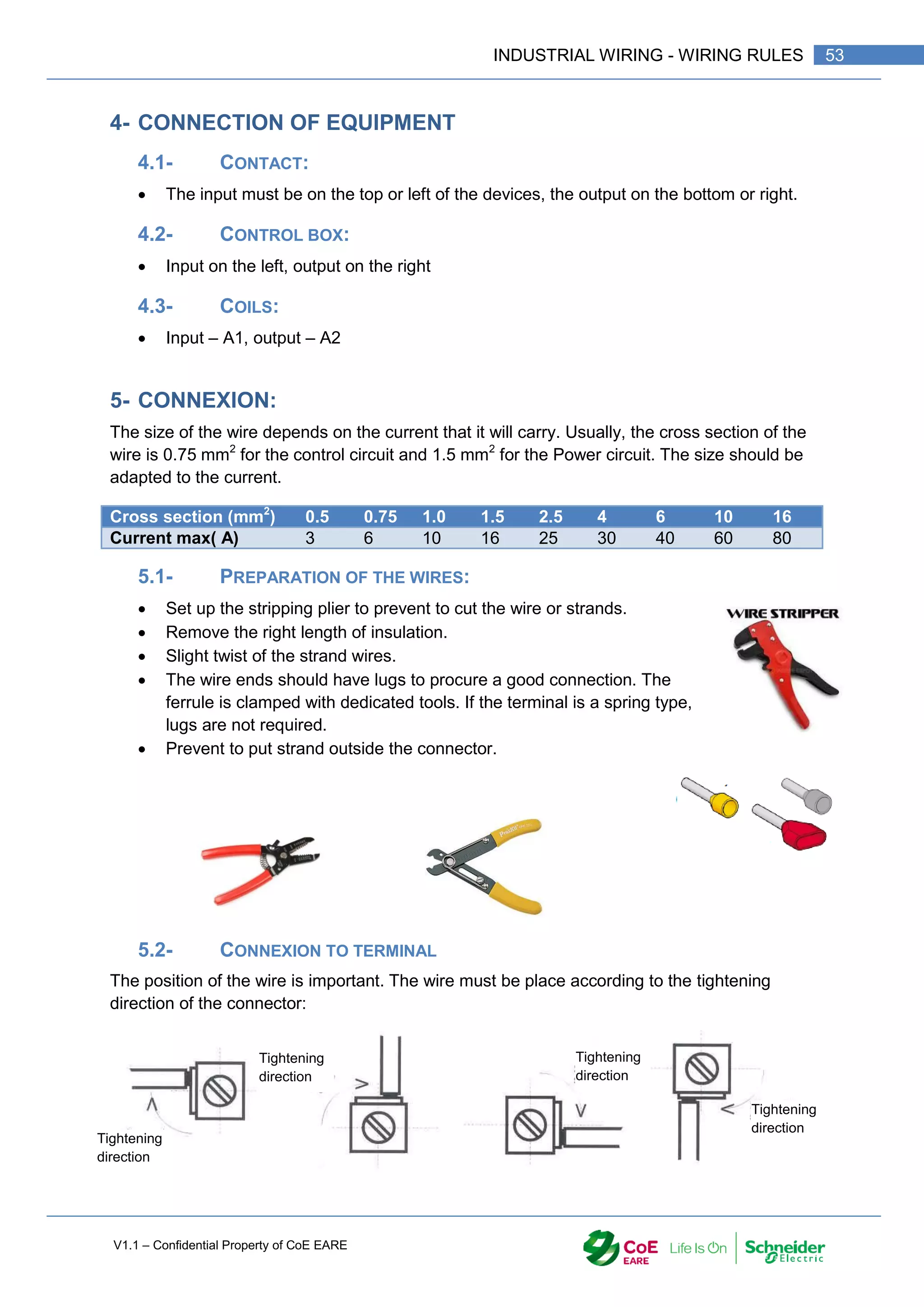

1- OBJECTIVE

Drawing and electrical circuit according to the standards.

Design an industrial electrical installation.

Understanding wiring procedure

2- HARDWARE LOCATION:

To implement the devices on a mesh in cabinet, it is recommended following the rules

hereafter:

2.1- SPACE BETWEEN

DEVICES:

Wiring by using raceway: leave

4 to 6 cm between the devices

and the raceway.

Wiring in strand: Leave 4 to 6

cm between devices

2.2- COMMON

FUNCTIONS:

it is recommended to place

side to side the equipment with

common function e.g.

contactor forward / reverse,

contactor going up / down…

The rating plate of the contactor coil should be accessible for reading.

3- WIRE COLOUR:

For the power circuit the following colour should be used:

Phase 1: Brawn (red)

Phase 2: Black (Yellow)

Phase3: Grey (Black)

Neutral: Blue

Earthing: Yellow /green

Note that the phases can be wired with one colour; in this case, the marking is mandatory.

The control circuit will be wired in grey. Other colour can be used but the marking is

mandatory.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-54-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

54 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

If there is two wire, place them on both sides of the terminal

Note that two wire maximum must be connected to one terminal.

5.3- WIRING RULES:

Regarding the wiring in raceway, the following rules must be followed:

Wire the power circuit before the control circuit.

For the control circuit: wire first the coil return (A2 terminals) then the button box, then

the cabinet door and finally the mesh.

The bridge between two terminals should be run

through the raceway.

The length of the wire should be enough to

shape it.

Wire must come perpendicularly to the device or

terminal

Wire terminal block from left to right and from

top to bottom.

For a comb wiring, wire must be parallel

The link to the loads, sensors should be made by cables.

The identification of the wire is given by the equipotential number on the diagram.

This identification can be letters, numbers or both. The identification is made with

ring, clips or direct printing.

All devices should be marked with specific tag.

Check the tightening.

5.4- WIRING PROCEDURE

Check with Multimeter the state of the contact](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-56-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

56 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

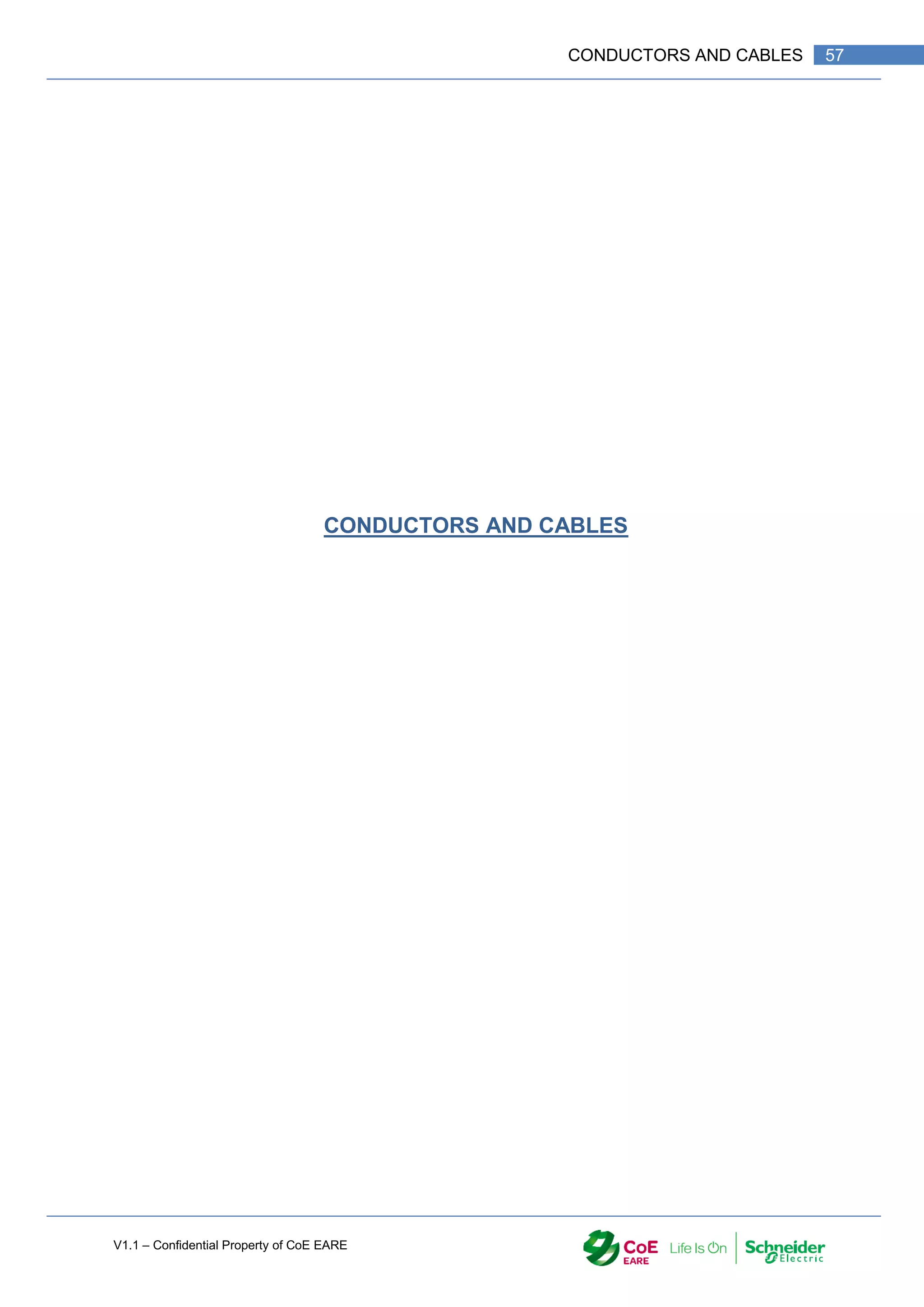

7.2- REAL WIRING DIAGRAM](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-58-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

58 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

1- OBJECTIVE

Select the equipment in order to design an electrical circuit

Design an industrial electrical installation.

2- CONDUCTORS AND CABLES:

They are the active part of the electrical links. Their duty is to carry the electrical

current. There is a large range of conductor and cable.

- An insulated conductor is an association between a conductor and insulation

- A single core cable is an Insulated conductor with one or more protective sheath.

- A cable is a bundle of conductors electrically insulated sharing the protective sheath.

3- GENERAL STRUCTURE.

A conductor or Cable is made with two essentials parts; each has its own function

(conductive or insulating)

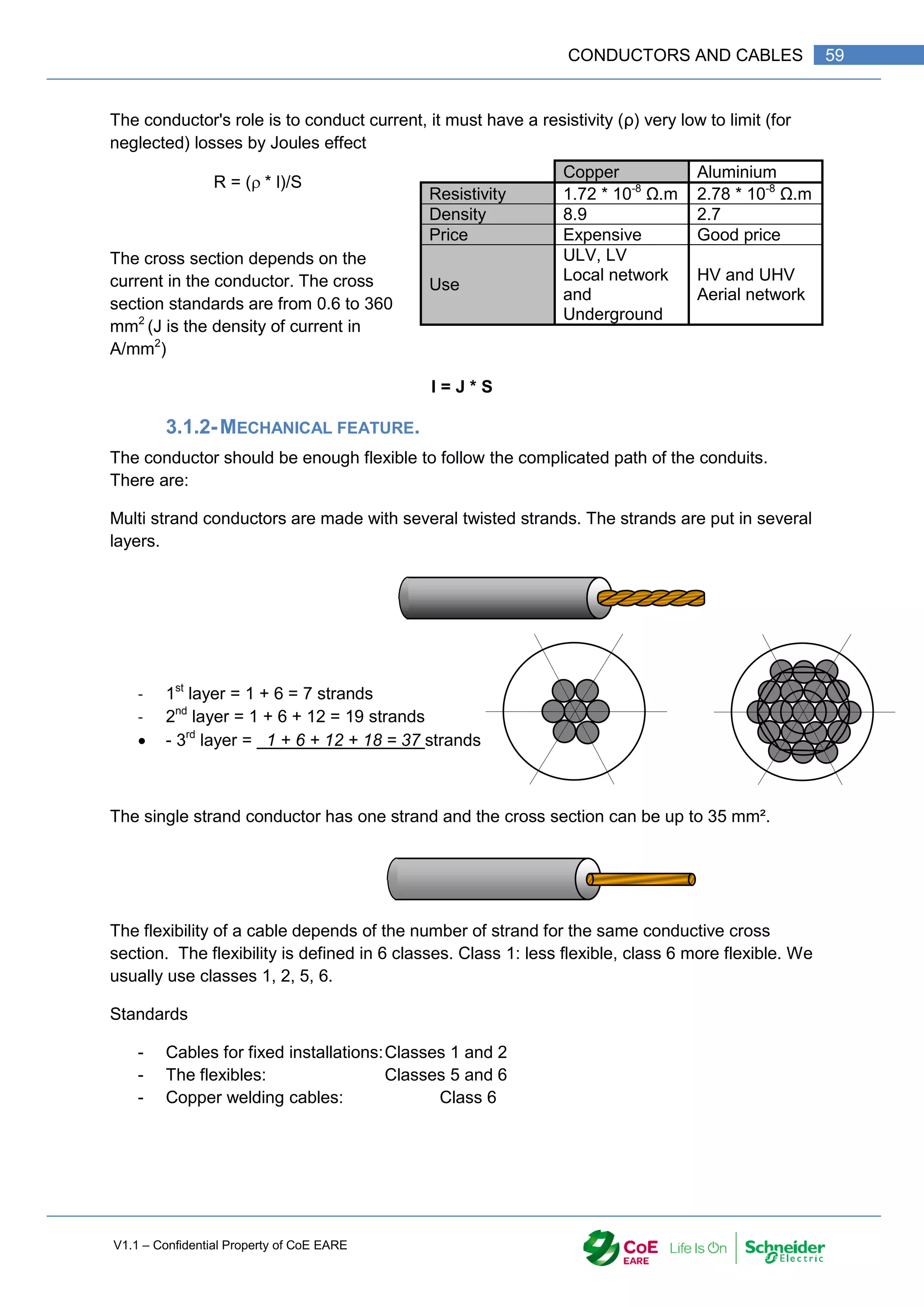

3.1- CONDUCTIVE PART.

3.1.1-ELECTRICAL FEATURES.

Conductor

Insulation

Protective sheath

Insulation

Conductor

Protective sheath

Conductor

Insulation](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-60-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

60 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Class 1 Class 2 Class 3 Class 4 Class 5 Class 6

médiocre

Poor

Solid

Conductor

Passable

Passable

Bon

good

Tres bon

Very good

Excellent

Excellent

Exceptionnel

Exceptional

Extra-flexible

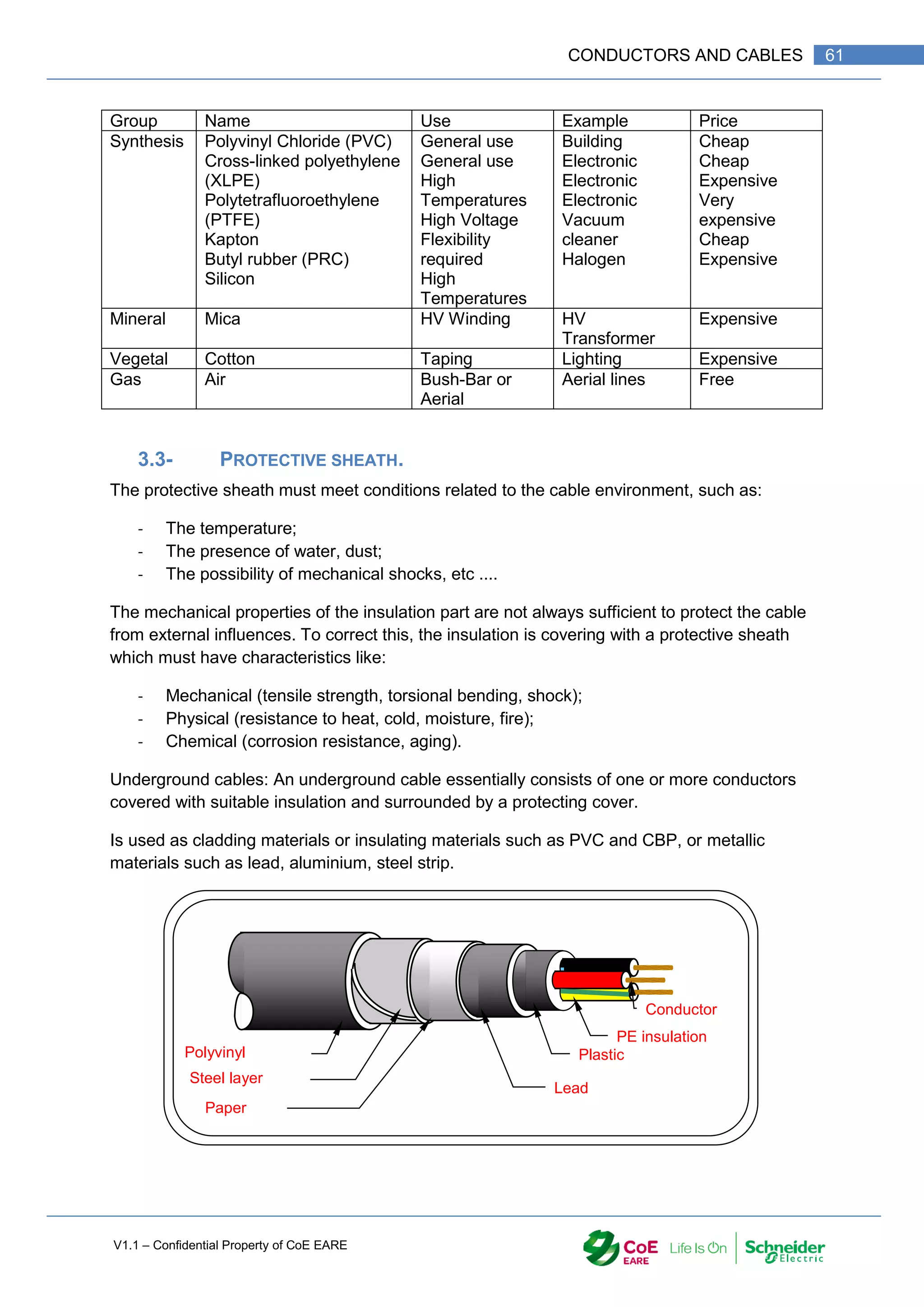

3.2- INSULATION PART: (DIELECTRIC)

Insulation performs the insulation between conductors with different voltages and the ground

or the earth. The insulation should have a very high resistivity.

Currently, synthetic plastics have replaced insulator like paper, natural rubber. The main

insulation is made with:

- Polyvinyl chloride (PVC) or polyethylene (PE)

- Chemically cross-linked polyethylene (PRC)

Insulations used are characterized for their rated voltage isolation. The nominal voltage of

the cable must be at least equal to the nominal voltage of the installation (different voltages

250V, 300V, 500V, 750V, 1000V).

Cross

section

Conductors Cross

section

Conductors

mm² Class 1 Class 2 Class 3 mm² Class 4 Class 5 Class 6

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

300

400

500

630

800

1 000

1 x 1.38

1 x 1.78

1 x 2.25

1 x 2.76

1 x 3.57

1 x 4.50

1 x 5.65

1 x 6.60

7 x 2.93

19 x 2.85

19 x 3.20

37 x 2.85

37 x 3.20

7 x 0.50

7 x 0.67

7 x 0.85

7 x 1.04

7 x 1.35

7 x 1.70

7 x 2.14

7 x 2.52

19 x 1.78

19 x 2.14

19 x 2.52

37 x 2.03

37 x 2.25

37 x 2.52

61 x 2.25

61 x 2.52

61 x 2.85

61 x 3.20

127 x 2.52

127 x 2.85

127 x 3.20

12 x 1.04

19 x 1.04

19 x 1.35

16 x 1.53

27 x 1.53

37 x 1.57

37 x 1.78

61 x 1.60

61 x 1.78

91 x 1.60

0.5

0.75

1

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

300

400

500

7 x 0.30

11 x 0.30

14 x 0.30

12 x 0.40

20 x 0.40

20 x 0.50

30 x 0.50

49 x 0.50

56 x 0.60

84 x 0.60

98 x 0.67

144 x 0.67

192 x 0.67

266 x 0.67

342 x 0.67

266 x 0.85

330 x 0.85

420 x 0.85

518 x 0.85

672 x 0.85

854 x 0.85

16 x 0.20

24 x 0.20

32 x 0.20

30 x 0.25

50 x 0.25

56 x 0.30

84 x 0.30

80 x 0.40

126 x 0.40

196 x 0.40

276 x 0.40

396 x 0.40

360 x 0.50

475 x 0.50

608 x 0.50

756 x 0.50

925 x 0.50

1221 x 0.50

1525 x 0.50

2013 x 0.50

1769 x 0.60

28 x 0.15

42 x 0.15

56 x 0.15

85 x 0.15

140 x 0.15

228 x 0.15

189 x 0.20

324 x 0.20

513 x 0.20

783 x 0.20

1107 x 0.20

702 x 0.30

909 x 0.30

1332 x 0.30

1702 x 0.30

2109 x 0.30

2590 x 0.30

3360 x 0.30

4270 x 0.30](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-62-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

62 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

4- CONSTRUCTION OF CABLES:

The various parts of underground cables are as under as shown in the picture.

4.1- LV CABLE

4.2- HV CABLE

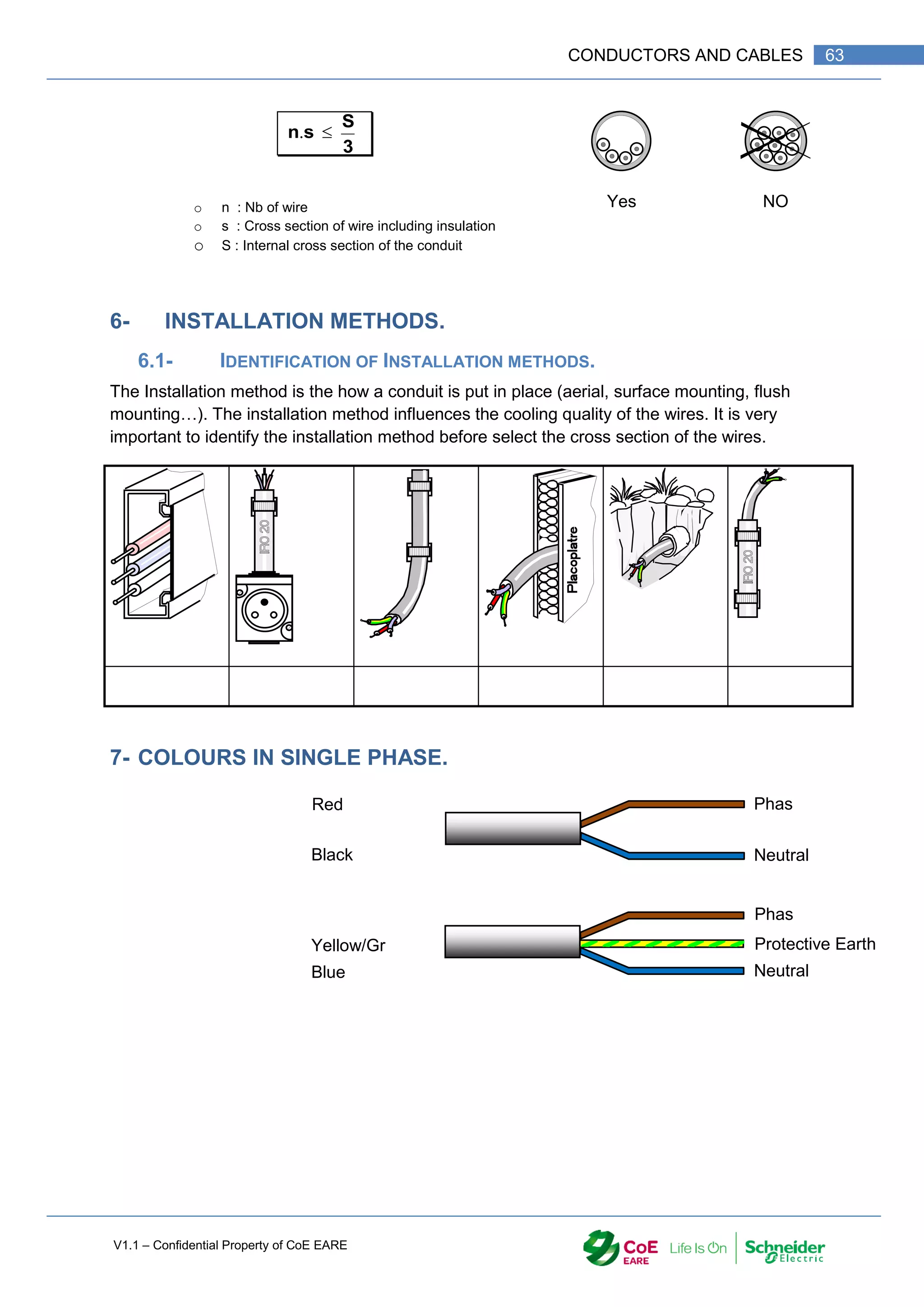

5- NUMBER OF WIRE IN A PIPE:

Whatever the conduit is, the cross section of wire should always be less than 1/3 of the cross

internal section of the conduct:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-64-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

64 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

8- COLOURS IN THREE PHASES

Phas

e

Neutral

Neutral

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Phas

e

Protective

Earth

Protective

earth

Grey

Yellow/Green

Brawn

Black

Black

Brawn

Grey

Grey

Black

Brawn

Blue

Grey

Black

Brawn

Blue

Yellow/Green](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-66-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

66 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

1- OBJECTIVE

Select the equipment in order to design an electrical circuit

2- DEFINITION

Electric converters : Electrical machines

We define an electrical machine as a converter Mechanical to Electrical or Electrical

to mechanical.

Electrical to Machanical => Motors Mechanical to Electrical => Generator

2.1- CHOOSE OF AN ELECTRICAL MACHINE:

The choice of an electrical machine depends on the inputs an doutput energies

Electrical :

The network ;

The characteristics ;

…

Mechanical :

The torque ;

The speed (rotation or linear) ;

The Power …

In addition to these fundamental characteristics for the choice of an electric machine, other

criteria must nevertheless be taken into account.

Among others:

The environment (definition of the IP, the IK, the temperature class, the altitude of

operation, nature of the atmosphere ....)

Operating service;

The dimensions of the machine (shaft height, ...);

The operating position (Vertical, Horizontal);

Examples of Electromechanical converter:

DC machine (Motor or Dynamo);

Asynchronous machine (Engine or Generator);

Synchronous machine (Engine or Alternator);

Special machines (2-speed asynchronous motor, stepper motor, linear motor ...)

Motor

Convert

Energy

Electric

Mechanic

Mechanic

Electric

Generator](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-68-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

68 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

4.1- TRANSMISSION CHAIN :

Network

Power circuit Motor K load

Motor

Axel

Pa m

Pu

Tm

m

K=r/m

r

Pc

c

Tc

J

Pa : Absorb power in W or KW ;

m : Efficiency (m= Pu / Pa) ;

Pu : Output power W ou kW (Pu = Tm m) ;

Tm : Torque Nm ;

m : Motor speed rad/s ;

K : Speed reducing ratio (K = r / m ) ;

r : Reduction gear’s efficiency (r = Pc/ Pu ) ;

Pc : Power required in W ou kW ;

c : Load speed in rad/s ;

Tc : Resisting torque in Nm ;

J : Moment of Inertia in kg/m2

;

We have to use the laws of mechanics to determine the parameters PU, m, Tm.

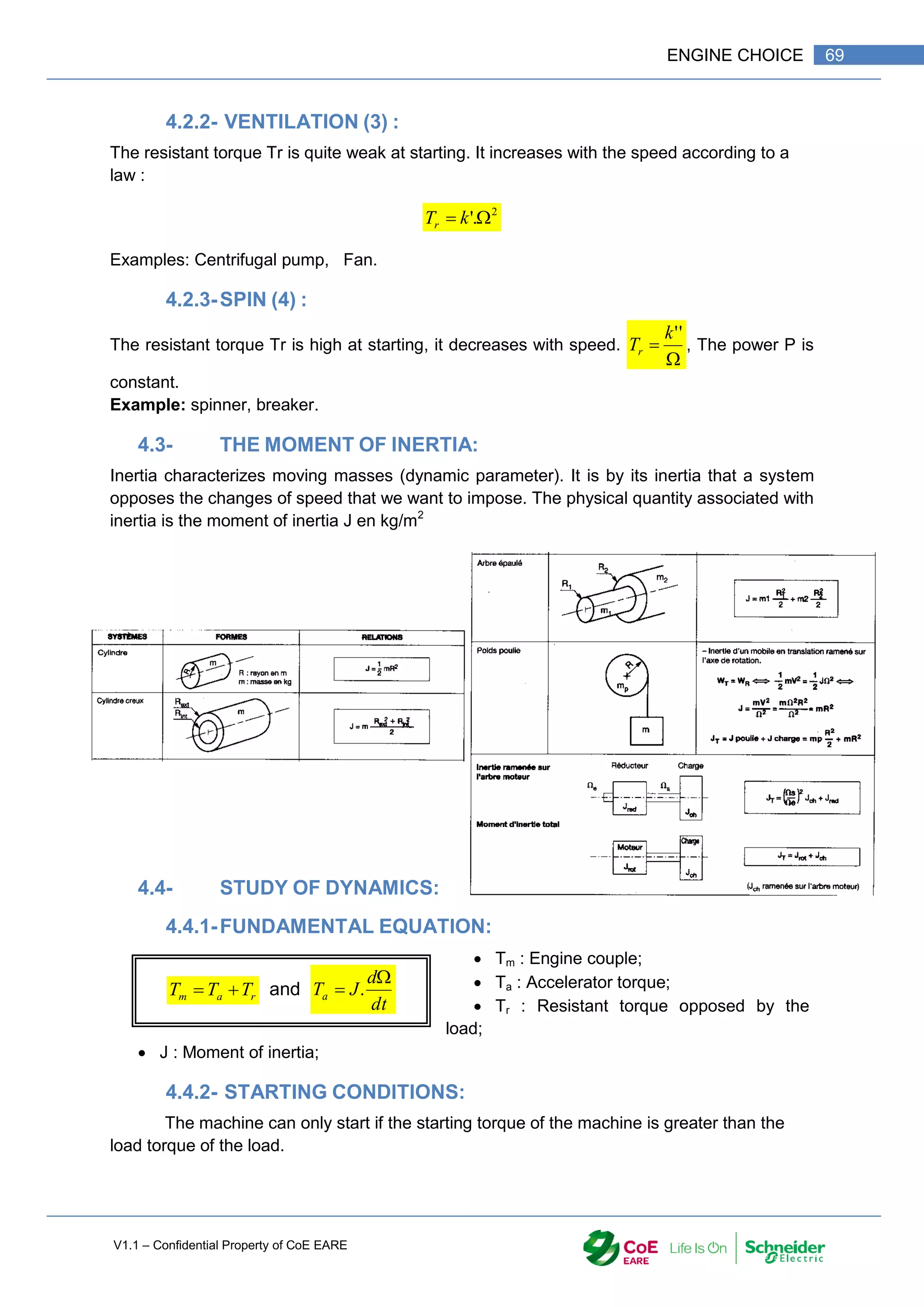

4.2- TYPE OF RESISTING TORQUE

The characteristic of the resistive torque as a function

of the speed defines the needs of the driven machine.

When this characteristic is not known, it is assimilated to

one of the three characteristics below.

4.2.1-PUMPING(1 AND 2):

The resistant torque Tr is quite strong at takeoff. It can be constant or grow slightly with

speed.

.

k

Tr Cte

Tr

Examples: Horizontal conveyor belt, lifting, Turbocharger.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-70-2048.jpg)

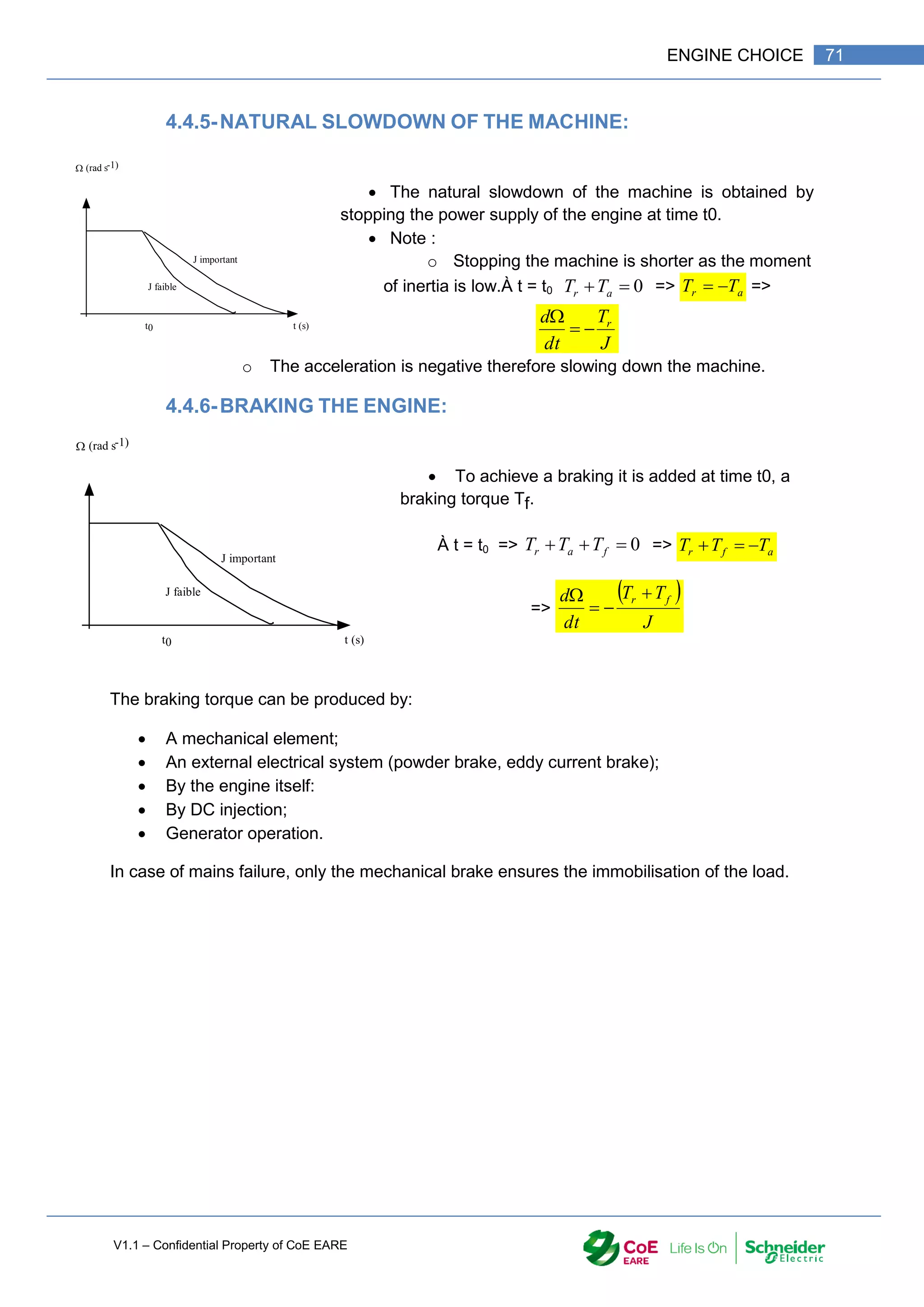

![V1.1 – Confidential Property of CoE EARE

70 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Examples :

The engine starts Td > TR0 The engine doesn’t start Td < TR0

The acceleration is higher as : Tm is bigger tahn Tr and J is small.

4.4.3-RUNING AT OPERATING POINT):

n steady state the speed is constant. So the acceleration torque no longer exists.

4.4.4-STABLE OPERATION OF THE MACHINE:

The stable operating point of the machine is the point

where the motor and resistive torque are equal.

Note:

The motor is generally chosen so that the operating point

A is as close as possible to the operation in nominal mode.

T (Nm)

Tm = f ()

(rad s-1)

Td

Tr = f ()

TR0

T (Nm)

Tm = f ()

(rad s-1)

Td

Tr = f ()

TR0

T (Nm)

Tm = f (V)

(rad s-1)

T

Tr = f ()

A

m

d T

T => r

m

a T

T

dt

d

J

T

.

Si cte

=> 0

dt

d

=> r

m T

T ](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-72-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

72 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

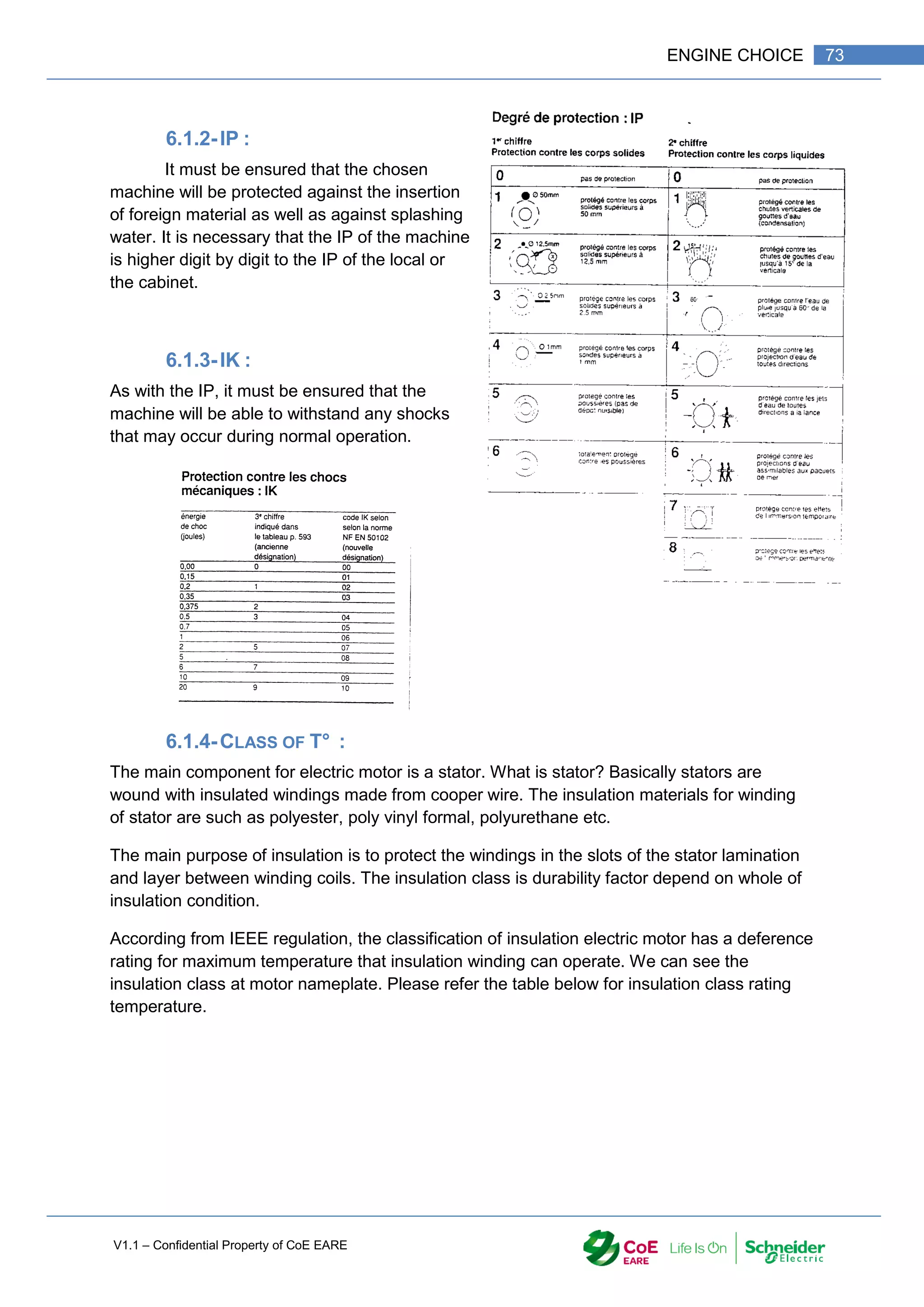

5- OPERATING QUADRANTS OF A MACHINE:

The working Quadrant are :

Motor : Q1 and Q3 (the engin provide a mechanic power)

Generator or Break; Q2 and Q4 (The engine is absorbing a mechanic power)

Direction Speed Torque Power Quadrant Work Load

Direction 1 +

+

+

-

+

-

1

2

Motor

Generator

Resistive

Leading

Direction 2 -

-

-

+

+

-

3

4

Motor

Generator

Resistive

Leading

6- OTHER CRITERIA FOR CHOOSING AN ELECTROMECHANICAL

CONVERTER:

6.1- CHOICE BASED ON THE ENVIRONMENT:

6.1.1-DECOMMISSIONING:

The normal conditions of use of standard machines are: a temperature between -16 ° C and

40 ° C; the altitude below 1000 m.

Corrections must be made outside these values.

𝑃𝑡𝑜 𝑖𝑛𝑠𝑡𝑎𝑙𝑙 = 𝑃𝐶𝑎𝑙𝑐𝑢𝑙𝑎𝑡𝑒𝑑 ∗

𝑃1

𝑃](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-74-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

74 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

The windings of a machine are coated with a varnish that

deteriorates with high temperatures. The standard has defined

temperature isolation classes that ensure proper operation for at

least 105

hours.

In the case where the machine used would work with a temperature higher than that of its

class, it is necessary to correct the life of the machine using the table of thermal aging of the

insulators.

For an ambient temperature> 40 ° C, the machine is downgraded according to the following

coefficients:

𝑃𝑡𝑜 𝐼𝑛𝑠𝑡𝑎𝑙𝑙 = 𝑘 ∗ 𝑃𝑐𝑎𝑙𝑐𝑢𝑙𝑎𝑡𝑒𝑑

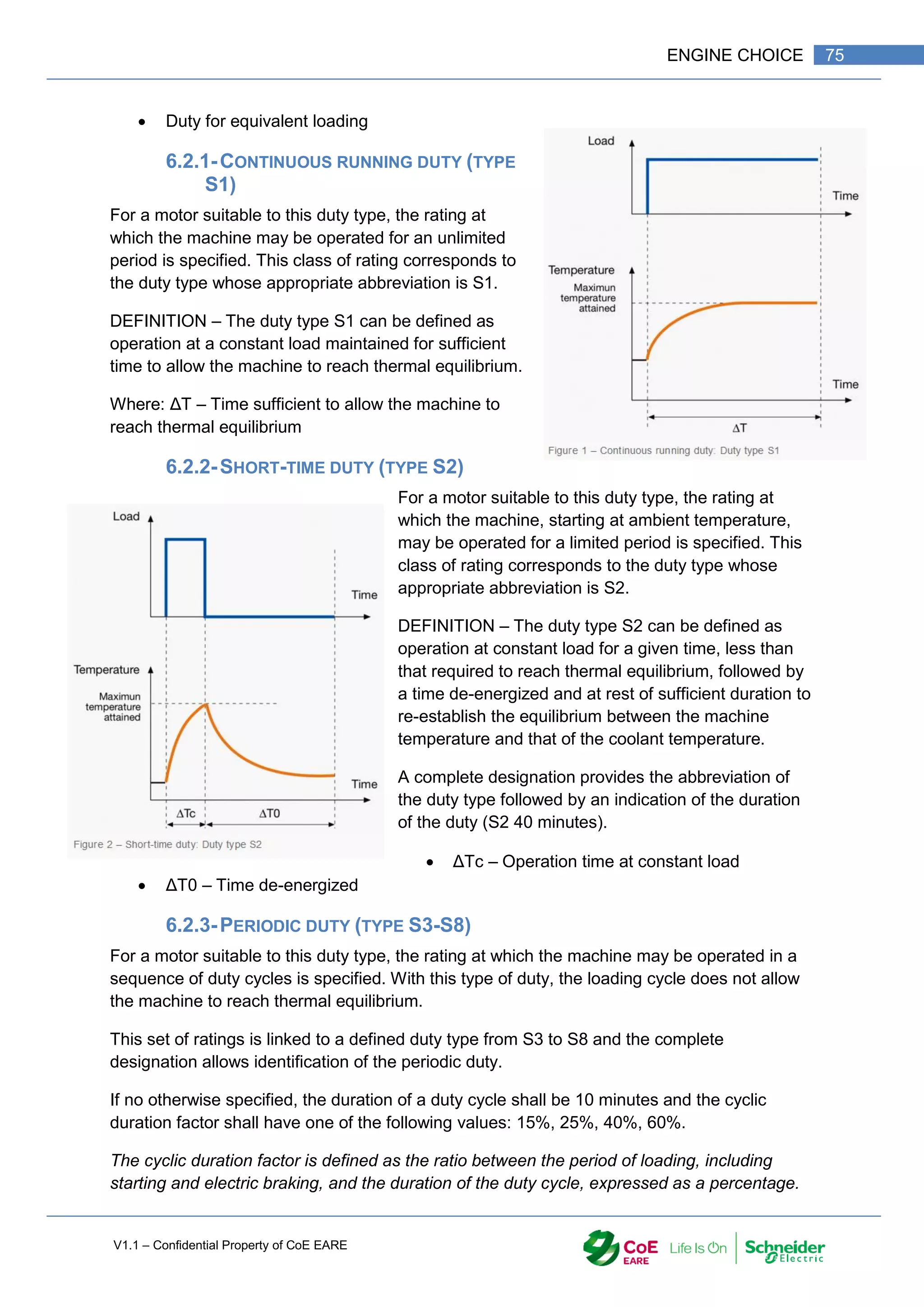

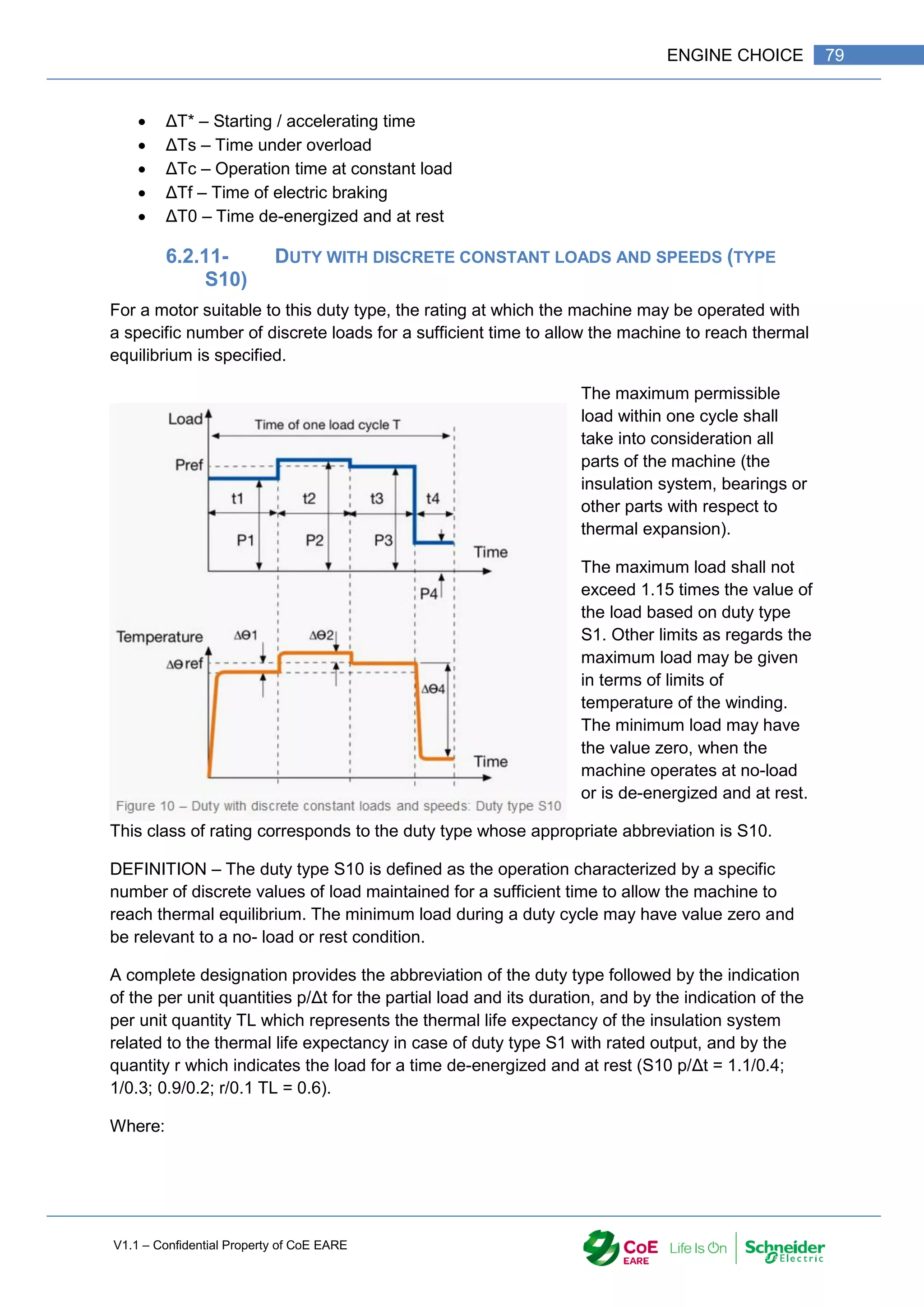

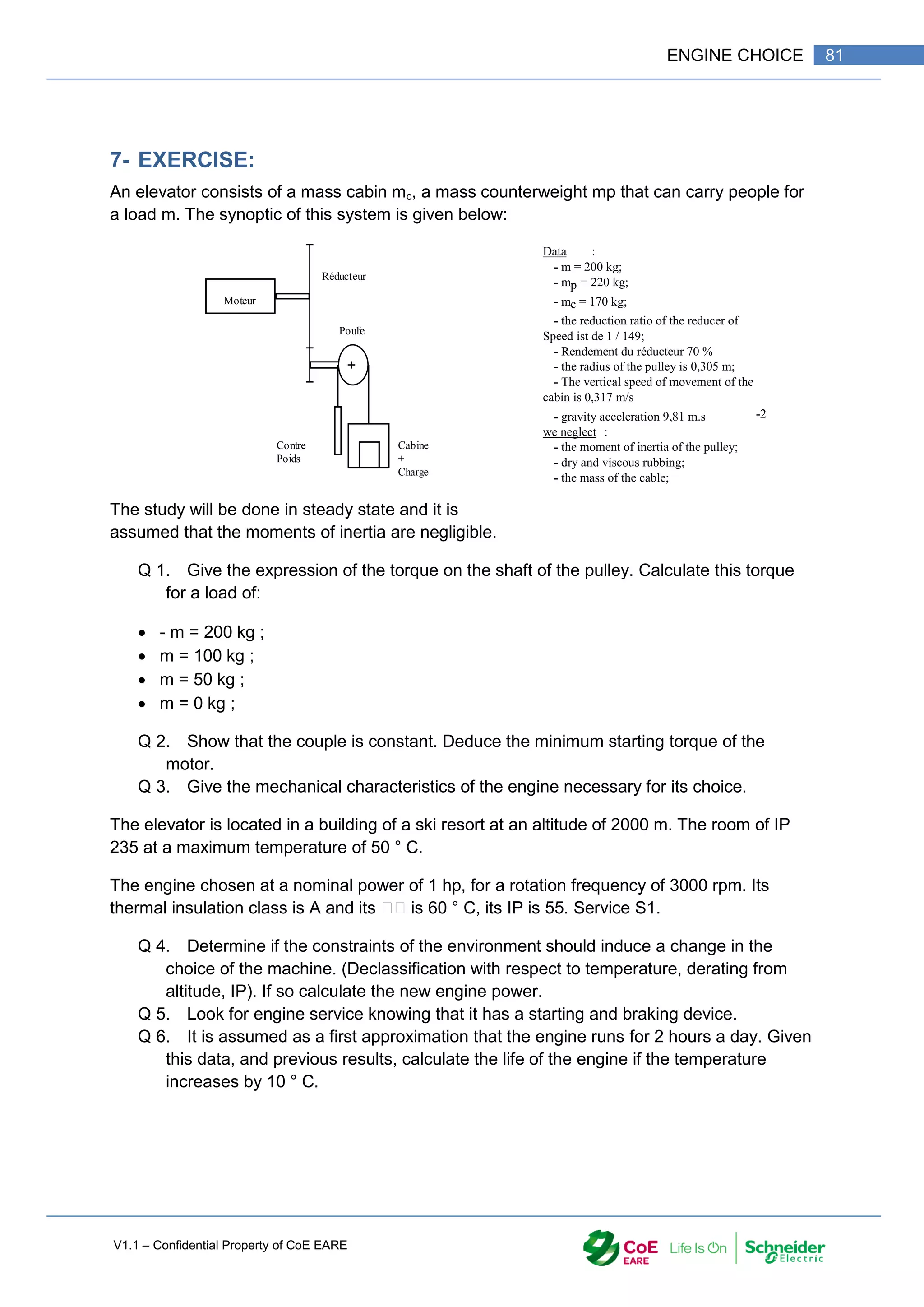

6.2- DUTY TYPES:

The choice of a machine is also conditioned by its operating conditions. Thus we define 8

"services" or Duty Types according to the operating conditions ('Start, Nominal operation,

idle operation, braking, stop).

In compliance with the classification of Std. IEC 60034-1 here are some indications regarding

the duty types which are typically considered as reference to indicate the rating of the motor.

Continuous running duty (type S1)

Short-time duty (type S2)

Periodic duty (type S3-S8)

o Intermittent periodic duty (Type S3)

o Intermittent periodic duty with starting (Type S4)

o Intermittent periodic duty with electric braking (Type S5)

o Continuous-operation periodic duty (Type S6)

o Continuous-operation periodic duty with electric braking (Type S7)

o Continuous-operation periodic duty with related load / speed (Type S8)

Non-periodic duty (type S9)

Duty with discrete constant loads (and speeds) – type S10

i k

45 °C 100/9

5

50 °C 100/9

0

55 °C 100/8

5](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-76-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

76 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

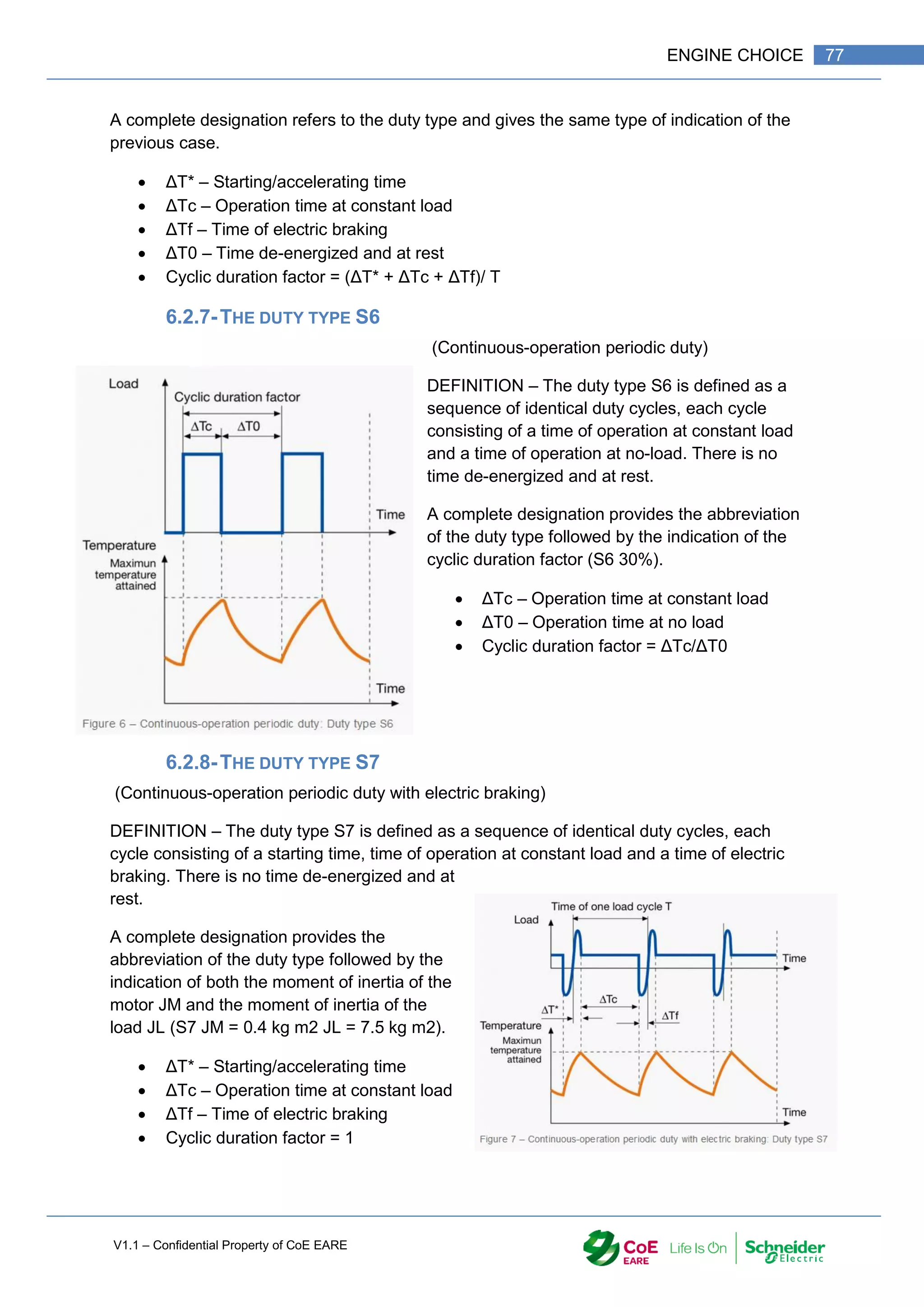

6.2.4-DUTY TYPE S3

(Intermittent periodic duty)

DEFINITION – The duty type S3 is defined as a

sequence of identical duty cycles, each including a time

of operation at constant load and a time de-energized

and at rest. The contribution to the temperature-rise

given by the starting phase is negligible.

A complete designation provides the abbreviation of the

duty type followed by the indication of the cyclic

duration factor (S3 30%).

ΔTc – Operation time at constant load

ΔT0 – Time de-energized and at rest

Cyclic duration factor = ΔTc/T

6.2.5-THE DUTY TYPE S4

(Intermittent periodic duty with starting)

DEFINITION – The duty type S4 is defined as a

sequence of identical duty cycles, each cycle

including a significant starting time, a time of

operation at constant load and a time de-

energized and at a rest.

A complete designation provides the

abbreviation of the duty type followed by the

indication of the cyclic duration factor, by the

moment of inertia of the motor JM and by the

moment of inertia of the load JL, both referred to

the motor shaft (S4 20% JM = 0.15 kg m2 JL =

0.7 kg m2).

ΔT* – Starting/accelerating time

ΔTc – Operation time at constant load

ΔT0 – Time de-energized and at rest

Cyclic duration factor = (ΔT* + ΔTc)/ T

6.2.6-THE DUTY TYPE S5

(Intermittent periodic duty with electric braking)

DEFINITION – The duty type S5 is defined as a

sequence of identical duty cycles, each cycle

consisting of a starting time, a time of operation

at constant load, a time of electric braking and a

time de-energized and at a rest.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-78-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

78 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

6.2.9-THE DUTY TYPE S8

(Continuous-operation periodic duty with related load / speed)

DEFINITION – The duty type S8 is defined as a sequence of identical duty cycles, each

consisting of a time of operation at constant load corresponding to a predetermined speed of

rotation, followed by one or more times of operation at other constant loads corresponding to

different speeds of rotation.

There is no time de-energized and at rest.

A complete designation

provides the abbreviation of

the duty type followed by the

indication of the moment of

inertia of the motor JM and by

the moment of inertia of the

load JL, together with the

load, speed and cyclic

duration factor, for each

speed condition (S8 JM = 0.7

kg m2 JL = 8kgm2 25kW

800rpm 25% 40kW 1250rpm

20% 25 kW 1000 rpm 55%).

ΔT* – Starting/accelerating time

ΔTc1; ΔTc2; ΔTc3 – Operation time at constant load

ΔTf1; ΔTf2 – Time of electric braking

Cyclic duration factor = (ΔT*+ΔTc1)/T; (ΔTf1+ΔTc2)/T; (ΔTf2+ΔTc3)/T

6.2.10- NON-PERIODIC DUTY (TYPE S9)

Duty with non-periodic load and speed variations

For a motor suitable to this duty type, the rating at which the machine may be operated non-

periodically is specified. This

class of rating corresponds to

the duty type whose

appropriate abbreviation is

S9.

DEFINITION – The duty type

S9 is defined as a duty in

which generally load and

speed vary non-periodically

within the permissible

operating range. This duty

includes frequently appplied

overloads which may greatly

exceed the reference load.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-80-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

80 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

ΔΘ1; ΔΘ2; ΔΘ2 – Difference between the temperature rise of the winding at each of

the various loads within one cycle and the temperature rise based on duty cycle S1

with reference load

ΔΘref – Temperature at reference load based on duty type S1 t1; t2; t3; t4: time of a

constant load within a cycle P1; P2; P3; P4: time of one load cycle

(Pref: reference load based on duty type S1)

6.2.12- DUTY FOR EQUIVALENT LOADING

For a motor suitable to this duty type, the rating, for test purposes, at which the machine may

be operated at constant load until thermal equilibrium is reached and which results in the

same stator winding temperature rise as the average temperature rise during one load cycle

of the specified duty type.

This class of ratings, if applied, corresponds to the duty type designated “equ”.

6.3- GEOMETRIC CRITERIA:

The size of the machine can in some cases cause problems. We must therefore

check the position (horizontal or vertical) and the dimensions of the machine.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-82-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

82 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

DC MOTOR](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-84-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

84 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

E R I

U

E’ R I

U

With E electromotive force,

E 'force against electromotive

R resistance of the armature

I current in the armature.

3.3- SPEED

Using previous relationships

For an engine For a generator.

k

I

r

U

k

I

r

U

3.4- THE POWER :

I

E

P

or I

E

P

'

3.5- ENGINE TORQUE :

I

k

P

T

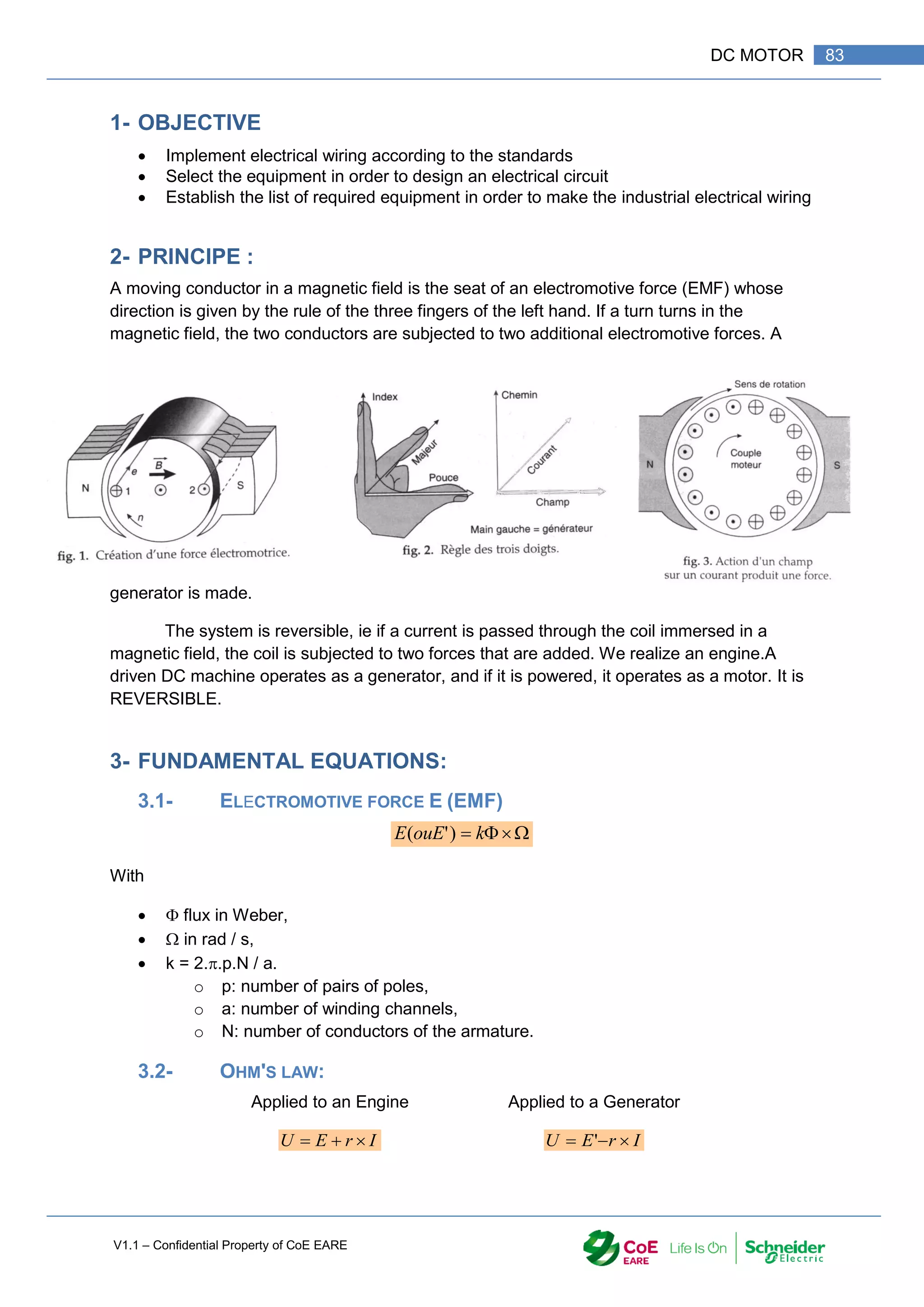

4- CONSTRUCTION :

The DC machine consists mainly of:

o A magnetic circuit to channel the flow;

o An inductive electric circuit to produce the flux and an induced electric circuit;

o A mechanical part to fix the different elements with respect to each other.

4.1- THE MAGNETIC CIRCUIT:

It consists of two parts:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-86-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

86 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

4.2.1-THE INDUCTOR:

It creates the magnetic flux in the main poles. The excitation power is about 2 to 3% of the

total power (5% for small machines).

The excitation winding can be shunted (or shunt (large number of turns in fine wires)) or in

series (small number of coils in thick wire) with the armature.

4.2.2-THE ARMATURE:

The winding of the armature is composed of a large number of sections formed of turns

whose ends are connected to two consecutive blades of the commutator.

4.2.3-THE COMMUTATOR:

It provides the connection between the rotating conductors and the external circuit. It

transforms the alternating current of the armature into direct current.

Crossing the neutral line, the commutator reverses the polarity of the conductors so that the

forces are always in the same direction.

The connection is made by graphite brushes which must be monitored for wear.

5- CHARACTERISTICS :

The DC machine is characterized by:

The nominal power of operation;

The armature voltage;

The speed of rotation;

The couple;

The power supply of the inductive circuit.

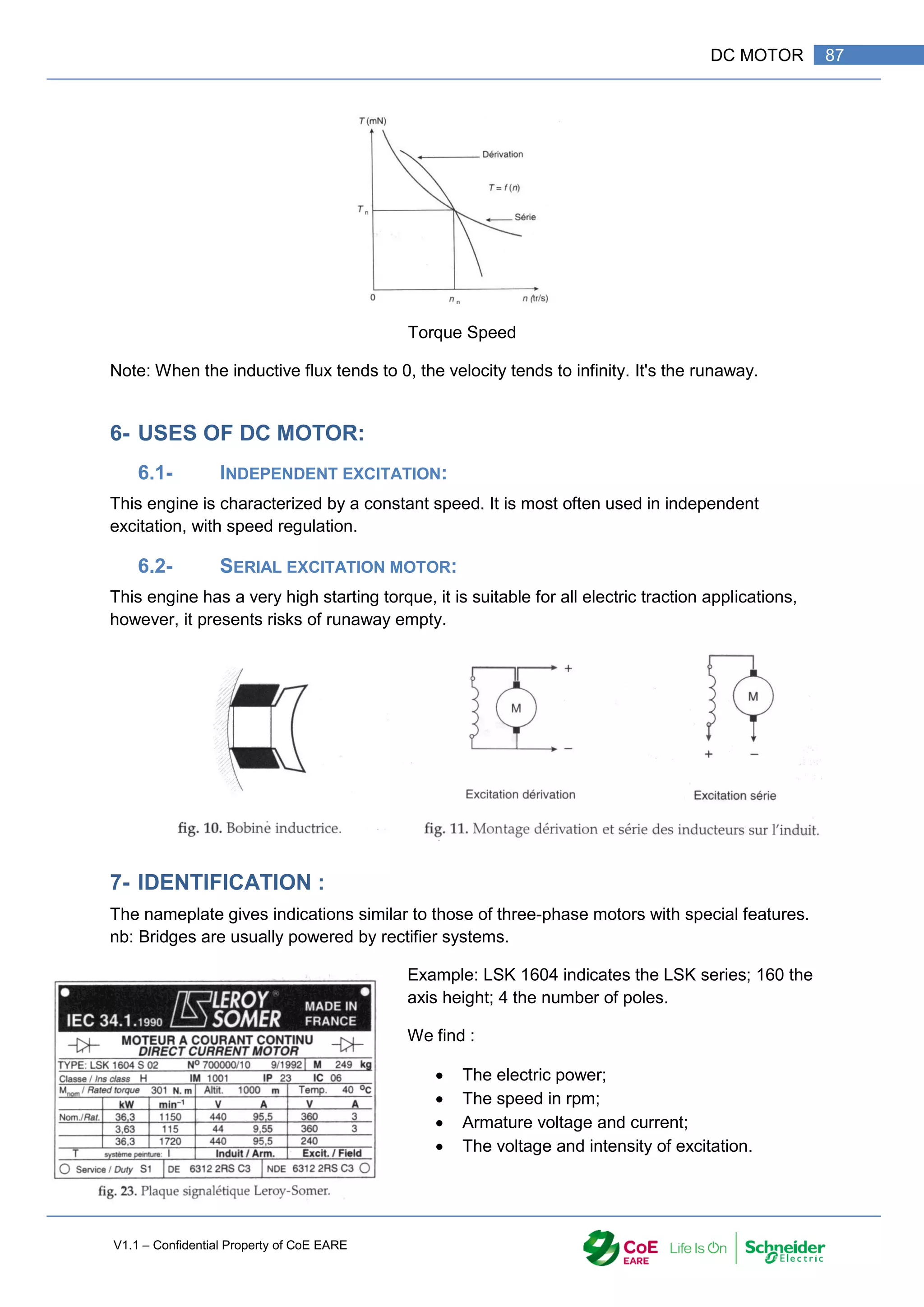

Characteristics of the operation according to the power supply of the inductor:

Current Speed: Current Torque:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-88-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

88 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

8- STARTING A DC MOTOR:

At power up, the motor does not rotate so the electromotive force is zero. The called current

is limited only by armature resistance. This results in a strong

starting current. To limit this current between 1.2 and 2 In, the

resistor is placed in series with the armature.

Contactor starter:

Km1: forward;

Km2: reverse,

K1 and K2 start contactor.

When starting a DC motor in Seri wiring, do not under any circumstances cut the excitation

before the armature.

9- EXERCICE :

A passenger transport system requires a DC motor to meet the specifications. It must

provide a torque of 58 Nm for a speed of 900 rpm.

Q 1. Calculate the useful power that the engine must supply. Look for the

characteristics of this engine in the course documentation.

Q 2. Give the model of the course the nameplate of the engine.

Q 3. We want a starting current of 2 In maximum. Calculate the starting resistances. We

will take k = 3.385.

Q 4. The motor is controlled by contactors. It works in both directions of rotation. Give

the power scheme for this operation. Using the telemechanical documents, look for

the reference of the different constituents of the power circuit.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-90-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

90 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

1- OBJECTIVE

Implement electrical wiring according to the standards

Select the equipment in order to design an electrical circuit

Establish the list of required equipment in order to make the industrial electrical wiring

2- INTRODUCTION

An induction motor or asynchronous motor is an AC electric motor in which the electric

current in the rotor needed to produce torque is obtained by electromagnetic induction from

the magnetic field of the stator winding. An induction motor can therefore be made without

electrical connections to the rotor. An induction motor's rotor can be either wound type or

squirrel-cage type.

Three-phase squirrel-cage induction motors are widely used as industrial drives because

they are rugged, reliable and economical. Single-phase induction motors are used

extensively for smaller loads, such as household appliances like fans. Although traditionally

used in fixed-speed service, induction motors are increasingly being used with variable-

frequency drives (VFDs) in variable-speed service. VFDs offer especially important energy

savings opportunities for existing and prospective induction motors in variable-torque

centrifugal fan, pump and compressor load applications. Squirrel cage induction motors are

very widely used in both fixed-speed and variable-frequency drive (VFD) applications.

The conversion of electrical energy is 80% by three-phase asynchronous motors thanks to

their simplicity of conversion, their robustness and their ease of starting.](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-92-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

92 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

An induction motor can be used as an induction generator, or it can be unrolled to form a

linear induction motor which can directly generate linear motion.

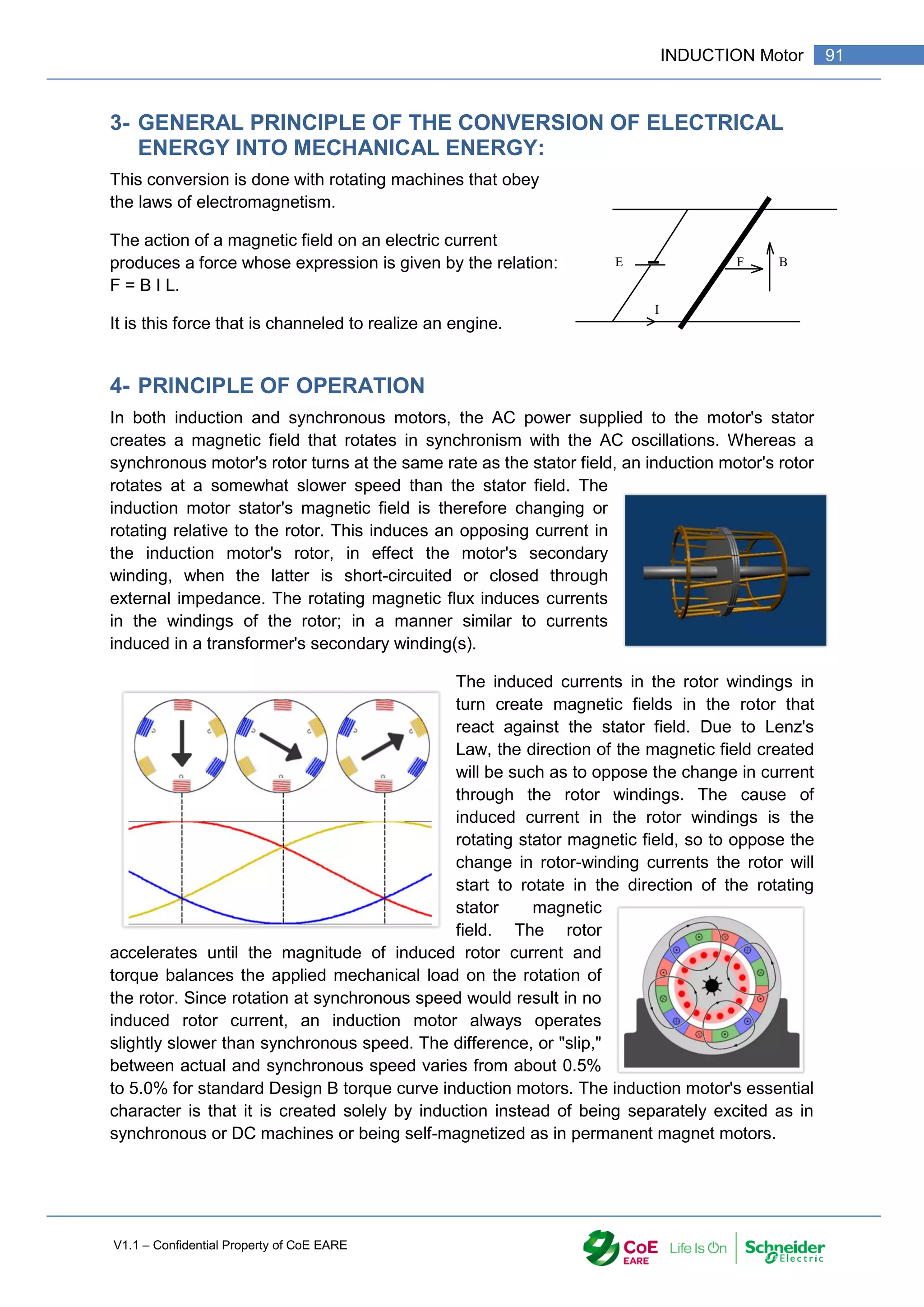

5- PRINCIPLE OF OPERATION OF THE ASYNCHRONOUS

MACHINE:

5.1- CREATING A ROTATING FIELD:

If three identical coils placed at 120 ° are

fed by a three-phase AC voltage:

A magnetized needle, placed in the

center, is rotated; So there is a creation of a

rotating field.

The needle is replaced by a metal disc

made of aluminum or copper. It is driven in the

same direction as the magnetic needle.

If two of the three three-phase power

leads are reversed, the needle or disc rotates in

the opposite direction.Principe de fonctionnement

de la machine asynchrone :

The three AC fields produced by the three-phase-fed coils are composed to form a rotating

field. The rotating magnetic field creates induced currents in the metal disk; These, according

to Lenz's law, oppose the cause that gave rise to them, and cause a magnetomotive force

that drives the disk in rotation.

The part containing the coils creating the magnetic field is called "STATOR". The moving part

under the influence of the magnetic field is called "ROTOR".

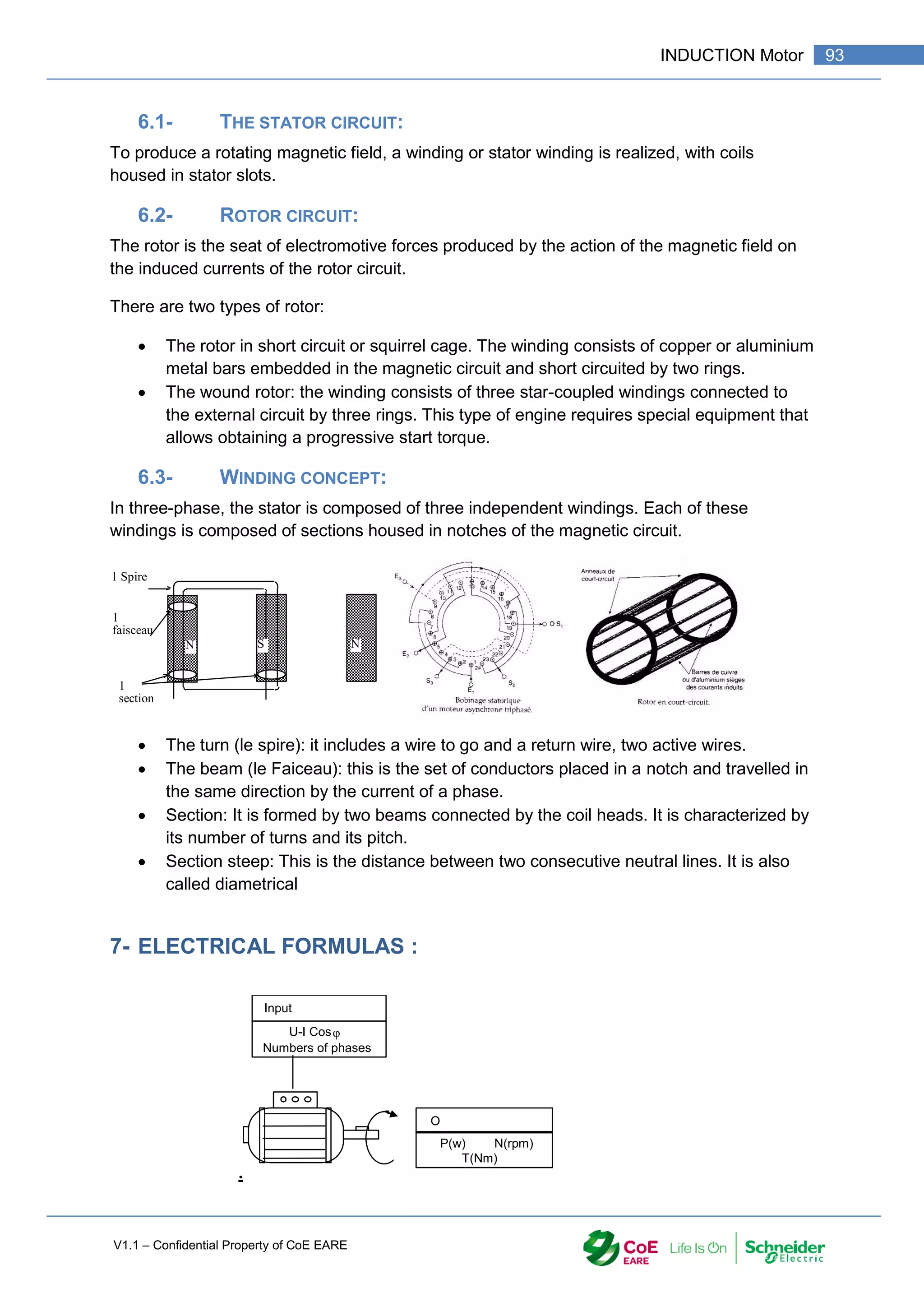

6- CONSTITUTION OF AN ASYNCHRONOUS MACHINE:](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-94-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

94 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

The asynchronous motor transforms the electrical energy supplied by the single-phase or

three-phase alternating current into mechanical energy. It is characterized by input quantities

that are electrical and by output quantities that are mechanical.

The electrical power absorbed by a three-phase asynchronous motor is:

Pa: Power in W (Watt); U: Voltage in V (Volts); I: Current in A (Amperes);

Cos : cosine of the phase shift angle between current and voltage.

Note: The current and voltage measurements can not give the power, Cos can vary

between 0.1 and 0.2 empty until 0.9 at full load.

The mechanical power is that obtained on the motor shaft:

Pu: Power in W (watt); Tu: Engine torque Newton-meter (Nm);

: angular velocity in radians per second (rad / s); n: Rotational speed in revolutions per second (rps).

Rated power: This is the mechanical power available on the motor shaft at its rated

speed.

Rated speed: The nominal speed is the speed at nominal power. We distinguish the

speed of synchronism (speed of the rotating field):

Where f is the frequency of the power supply, p is the number of magnetic poles, and ns is

the synchronous speed of the machine. For f in Hertz and ns in RPM, the formula becomes:

Slip, s is defined as the difference between synchronous speed and operating speed,

at the same frequency, expressed in rpm, or in percentage or ratio of synchronous

speed. Thus

Where ns is stator electrical speed, nr is rotor

mechanical speed.

Slip, which varies from zero at synchronous speed

and 1 when the rotor is at rest, determines the

motor's torque.

Cos

I

U

Pa

3

u

u T

P](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-96-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

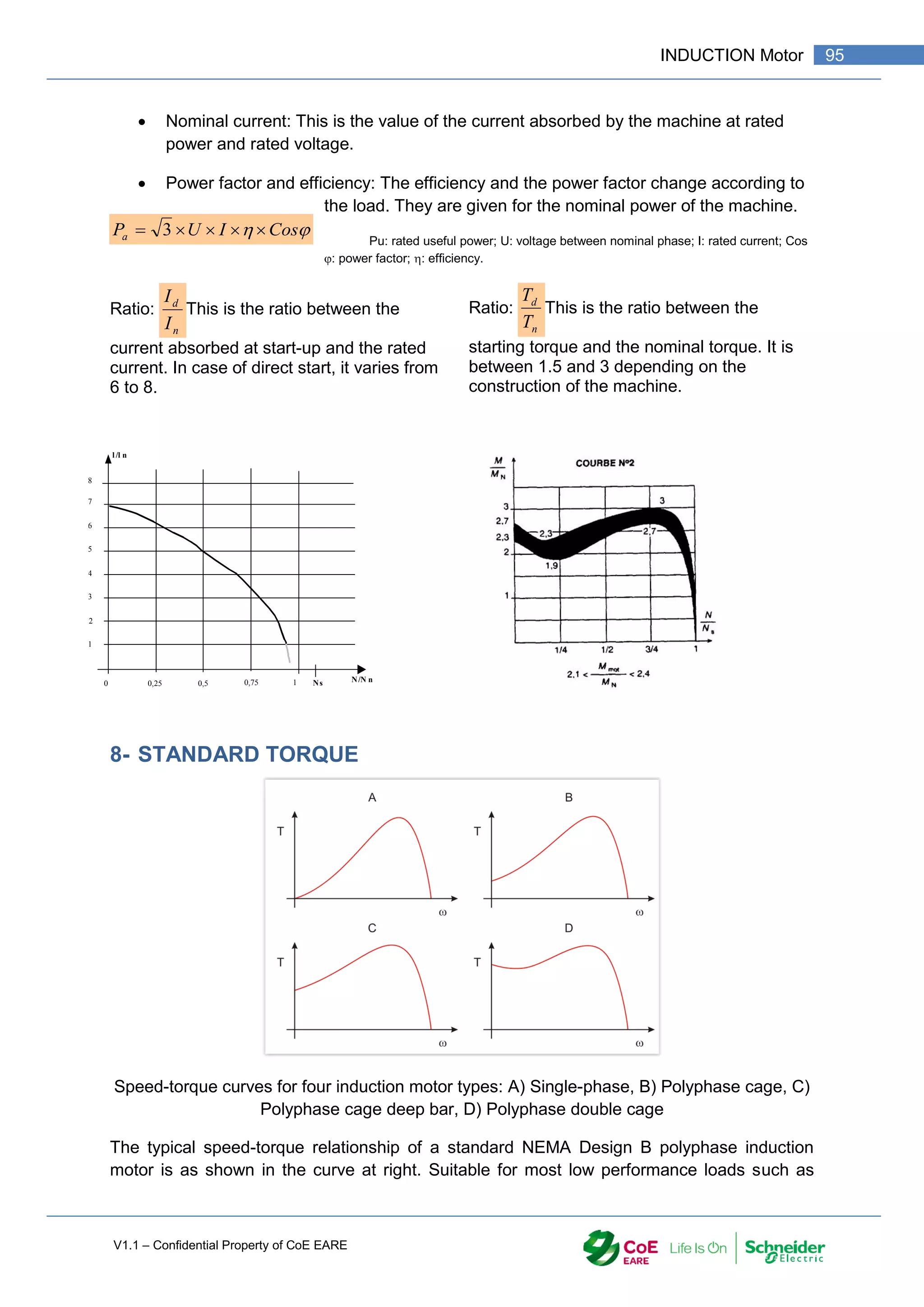

96 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

centrifugal pumps and fans, Design B motors are constrained by the following typical torque

ranges:

Breakdown torque (peak torque), 175-300% of rated torque

Locked-rotor torque (torque at 100% slip), 75-275% of rated torque

Pull-up torque, 65-190% of rated torque.

Over a motor's normal load range, the torque's slope is approximately linear or proportional

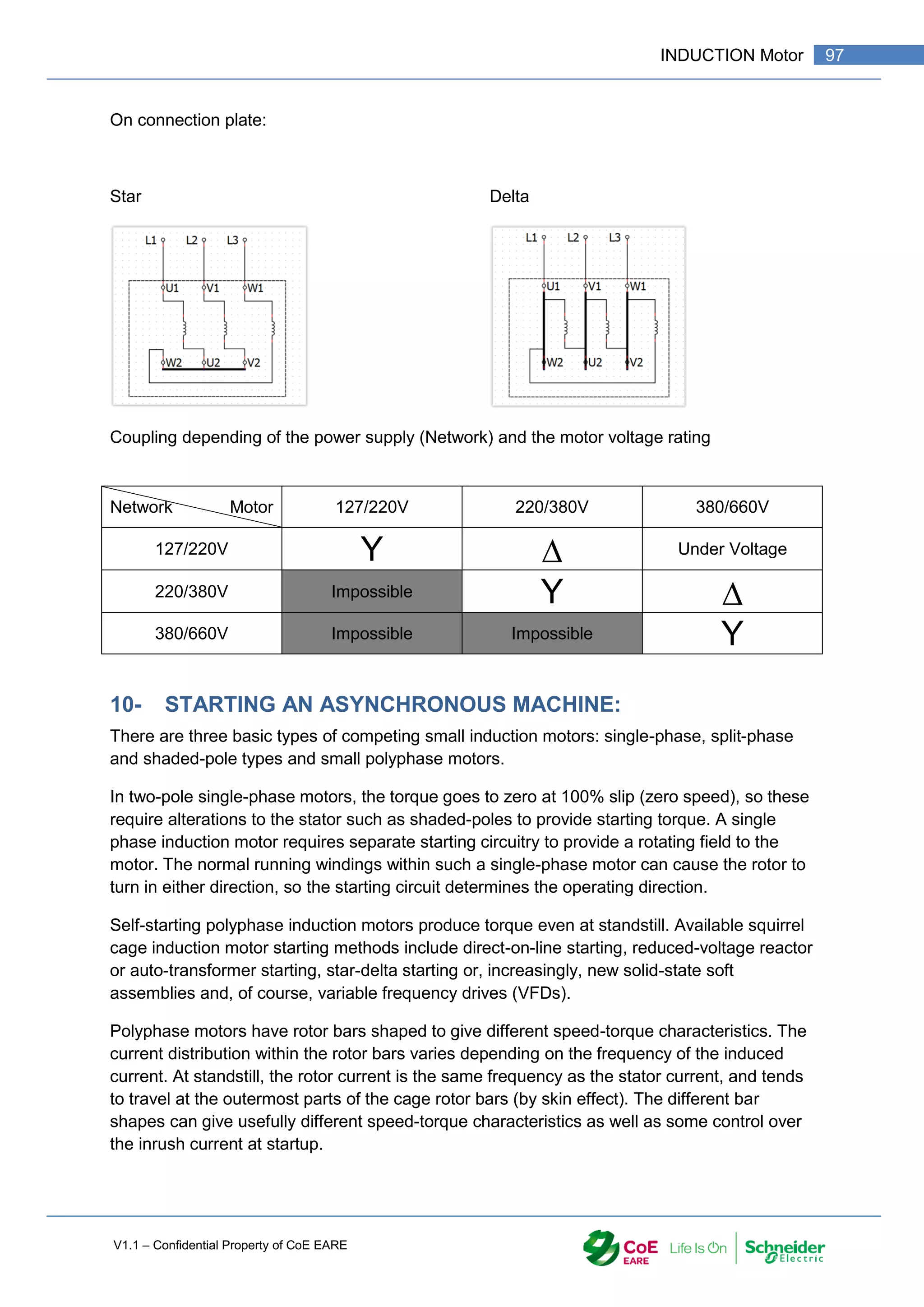

9- COUPLING

Induction motor is composed of three coils. One coil per phase. Each coil has a nominal

voltage and nominal current. These values are written on the rating plate of the motor.

The voltage of the power supply is important to know as it will define what will be the

coupling of the motor. An Induction Motor has two voltages with a ratio of √3. E.g. 220/380V

The lowest voltage is the maximum voltage a coil can handle. In this case, the voltage of the

power supply in important to know. For a power supply of 220/380V, the voltage between

phases is 380V.

There are two types of connection (coupling) for an induction motor:

Star, on end of the three coils are

connected together.

o U2, V2, W2 connected

together,

o Power supply on U1, V1,

W1.

Delta, all coils are in series.

o U1 connected to W2

o W1 connected to V2

o V1 connected to U2](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-98-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

98 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

In wound rotor motors, rotor circuit connection through slip rings to external resistances

allows change of speed-torque characteristics for acceleration control and speed control

purposes.

10.1- CASE OF THE STARTING TORQUE:

For an Induction Motor to start, the torque

demanded by the load on startup must be less

than the starting torque of the machine.

The machine produces the starting and stabilizes

at the point F which is the point of operation of

the system.

This point must be as close as possible to point

N (nominal point of the machine) to obtain

maximum energy efficiency.

10.2- DIRECT ON LINE :

Direct startup of an asynchronous machine causes a high starting current. Id = 6 to 8

In.

Make sure that the protections are not tripped: fuse use aM.

To avoid the disadvantage of the fuse aM (melting delay), the motor is protected

against overloads by a thermal tripping device

10.3- STAR – DELTA STARTING :

This type of startup avoids the disadvantage of the strong

current at startup. Indeed by using a reduced voltage at

startup, the current is limited.

3

d

d

I

I

3

d

d

T

T

The disadvantage lies in the weakness of the

starting torque.

Star Delta Starter can only be used if the starter-

resistant torque is zero or very low.

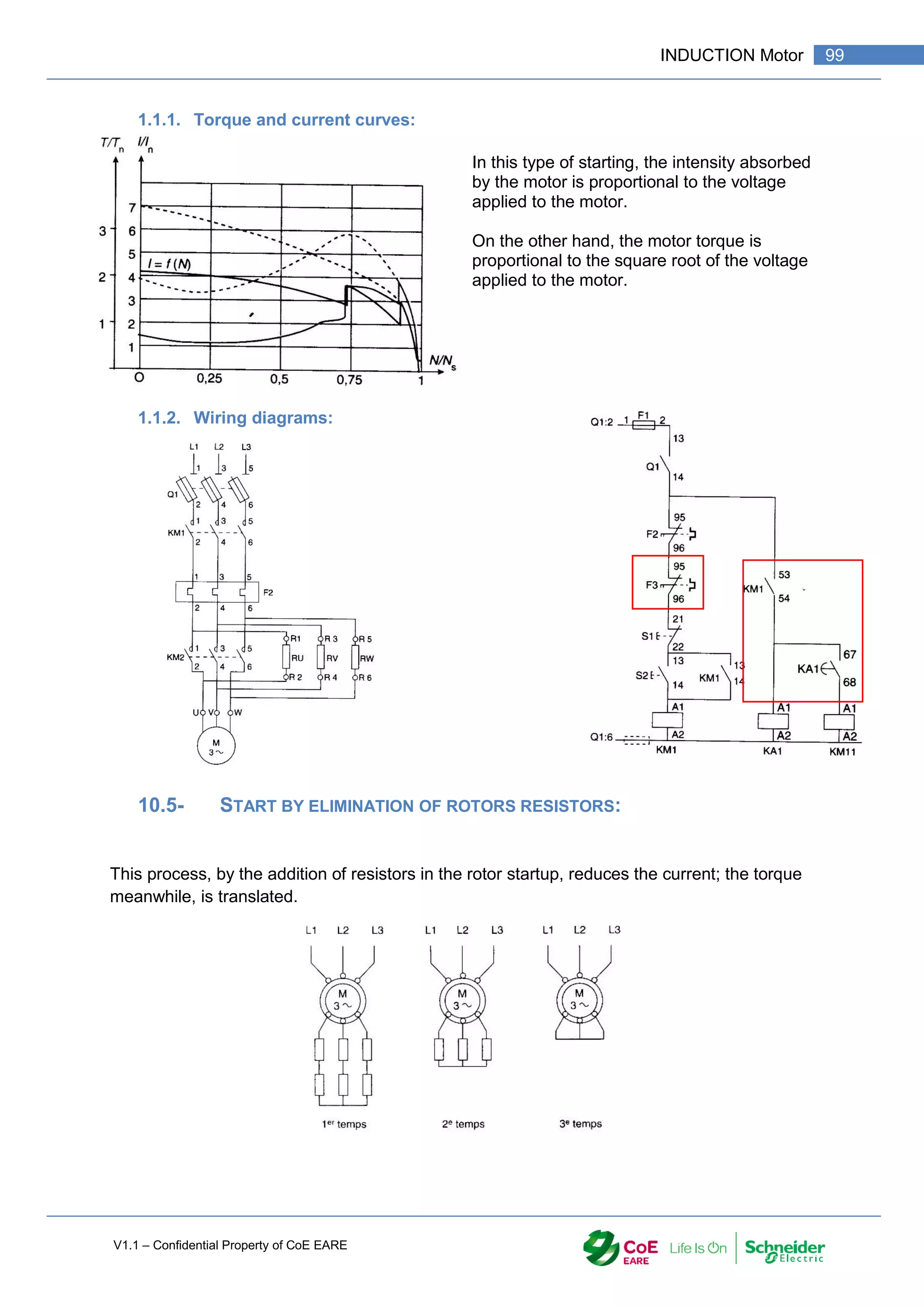

10.4- STATOR STARTER : STARTING BY ELIMINATING STATOR RESISTORS:

Always to eliminate the intensity peak at startup, work under

reduced voltage. This reduced voltage is achieved by

inserting stator resistors in series with the motor. We can

achieve a start in several times.

0

T

/Tn

1

2

3

4

0,25 0,5 0,75 N/Ns

Couple résistant

opposé par la charge

Couple Moteur

1

F

N](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-100-2048.jpg)

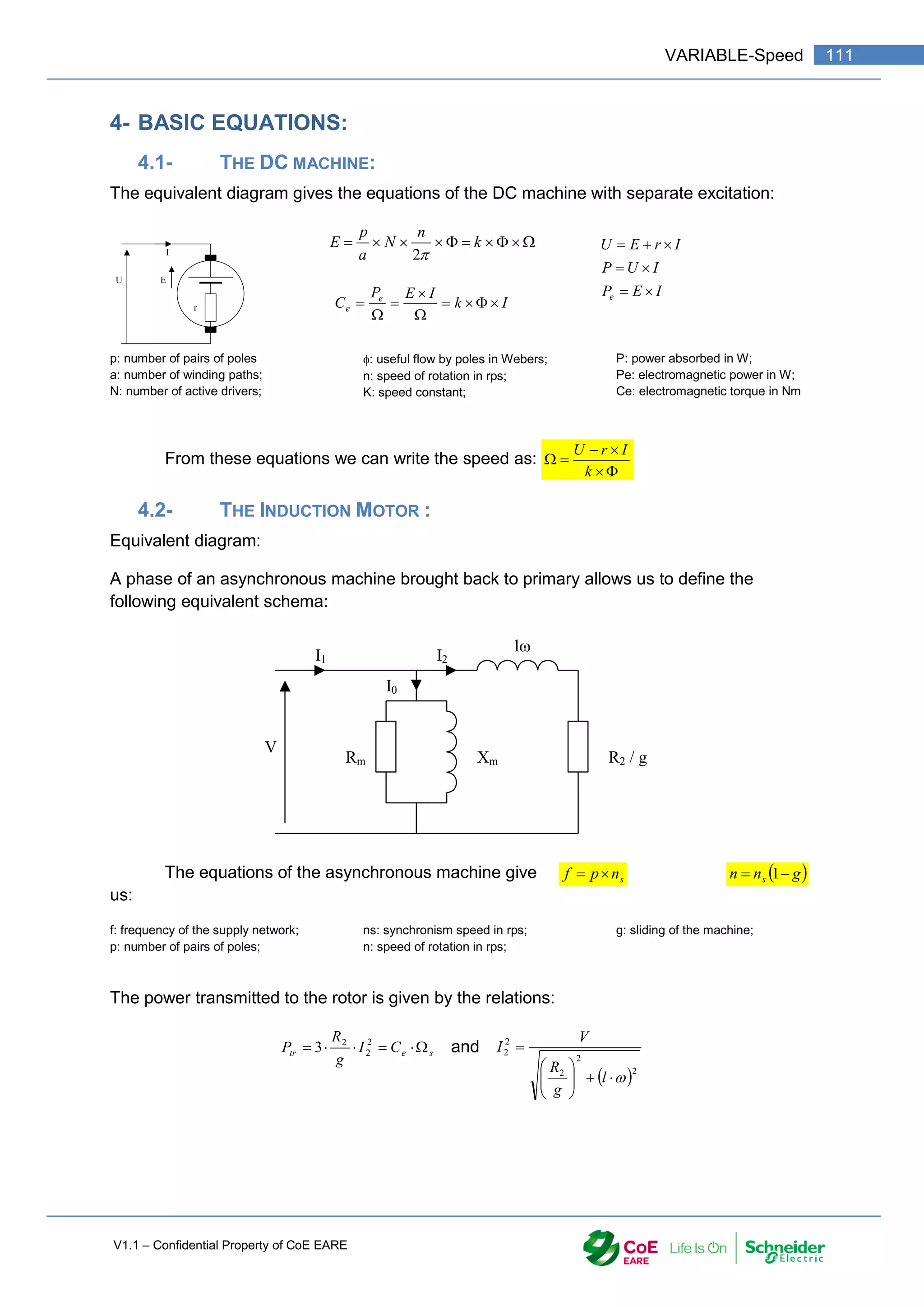

![V1.1 – Confidential Property of CoE EARE

100 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

10.5.1- TORQUE AND CURRENT CURVES:

This type of start allows for a lower absorbed current to obtain a torque at the start.

10.5.2- WIRING DIAGRAMS](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-102-2048.jpg)

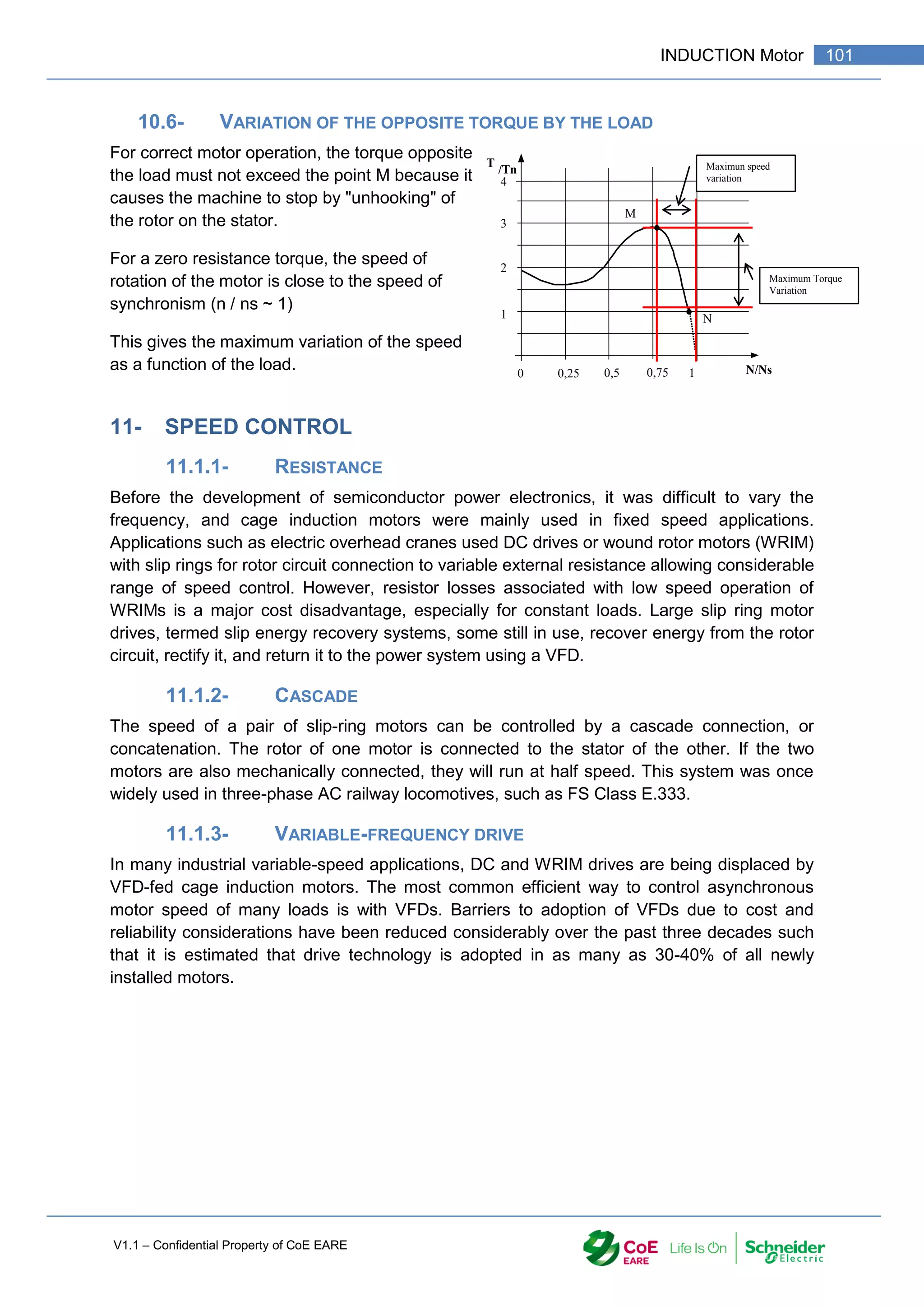

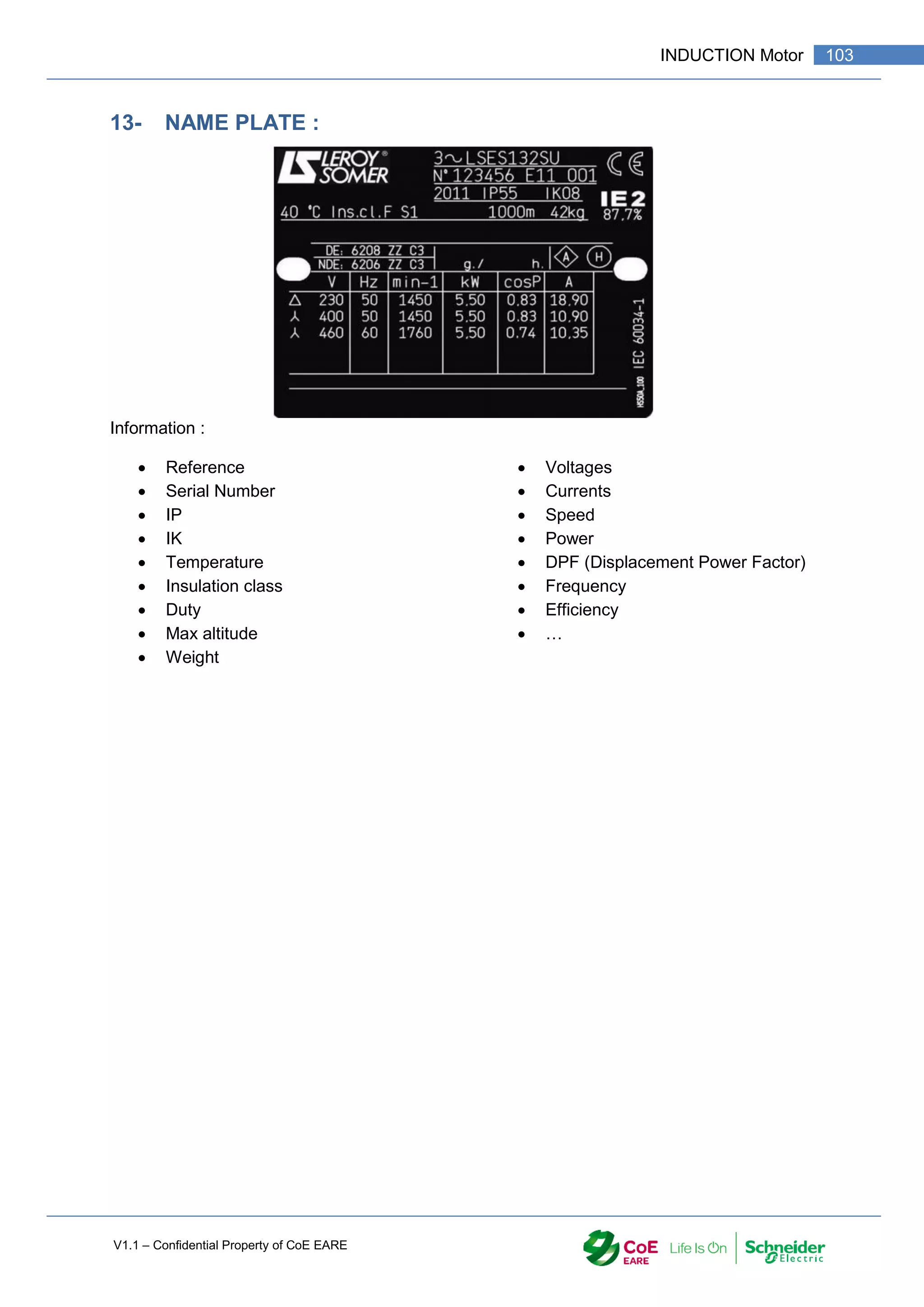

![V1.1 – Confidential Property of CoE EARE

102 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Typical speed-torque curves for different motor input frequencies as for example used with

variable-frequency drives

12- IN SUMMARY

Starter Direct Star Delta Stator Rotor

Initial current 4 to 8 In 1,3 to 2,6 In 4,5 In 2,5 In

Staring Torque 0,6 to 1,5 Tn 0,2 to 1,5 Tn 0,6 to 9,85 Tn 2,5 Tn

Average

duration

2 to 3 s 3 to 7 s 7 to 12 s 2,5 to 5 s

Advantages Simple and

costless starter

High starting

torque

Good ratio

Torque / Curent

Not too

expensive

No supply cut,

limitation of

Inrush current

Very good ration

Torque/Current

No power cut

Disadvantage High Inrush

current

Strong stating

Small staring

Torque, Power

cut when

changing from

Star to Delta

Need of

resistances

Small reduction

of the Inrush

Current

Winding Rotor

more expensive

Nedd of

resistances

Applications Small motor

power up to

5KW

Induction motor

starting without

loads

Engin with high

Inertia

Progressive

starting

Lift](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-104-2048.jpg)

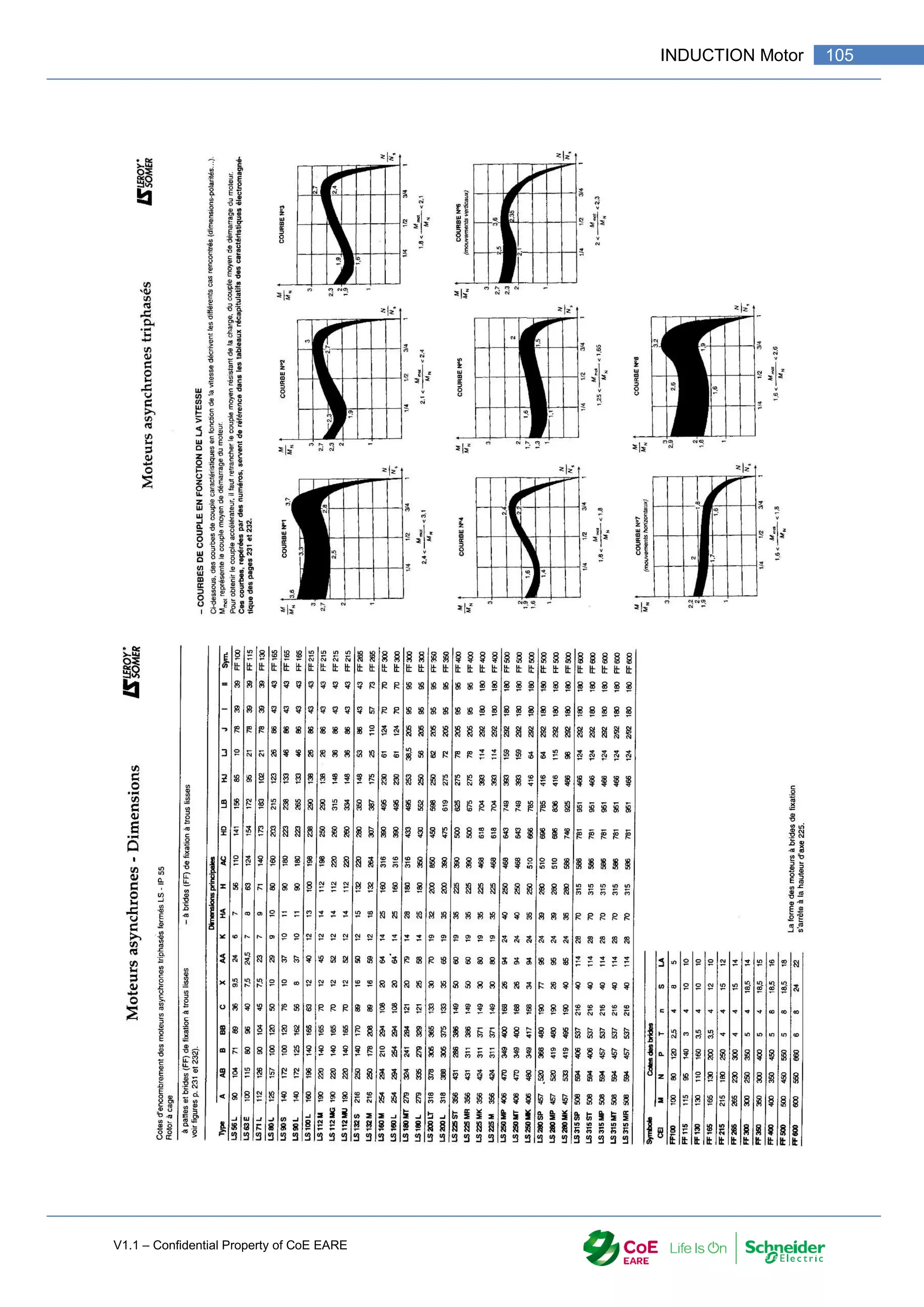

![V1.1 – Confidential Property of CoE EARE

104 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

14- EXAMPLE OF INDUCTION MOTOR](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-106-2048.jpg)

![V1.1 – Confidential Property of CoE EARE

106 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

15- MOTOR MOUNTING CODES

Proper motor installation and mounting position is essential in obtaining top-quality operation,

efficient performance, and maximum reliability. Sometimes, however, there is confusion

about the many different ways a motor can be installed.

There are two different standards—NEMA and IEC— which you will see when looking at

electric motor mounting positions. Although they are generally comparable, there are slight

differences between the two.

The standard IEC mounting position places the junction box on the top of the motor, known

as the IM B3 mounting position in IEC frame (or F3 in NEMA frames). On the other hand,

the NEMA standard mounting position is referred to as F1, with the junction/conduit box

located on the left side of the motor facing the output shaft.

The design of most motors is such that they can usually be operated in many mounting

positions, unless indicated otherwise. Some mounting positions, however, require additional

construction modifications to achieve optimal performance. For example, shaft-up or shaft-

down outdoor applications may require drilling of additional drain holes, drip covers and

stronger bearings to support heavy loads. Don't just assume you can bolt any motor in any

orientation!](https://image.slidesharecdn.com/iaindustrialautomation-part1-210930233627/75/Ia-industrial-automation-part-1-108-2048.jpg)

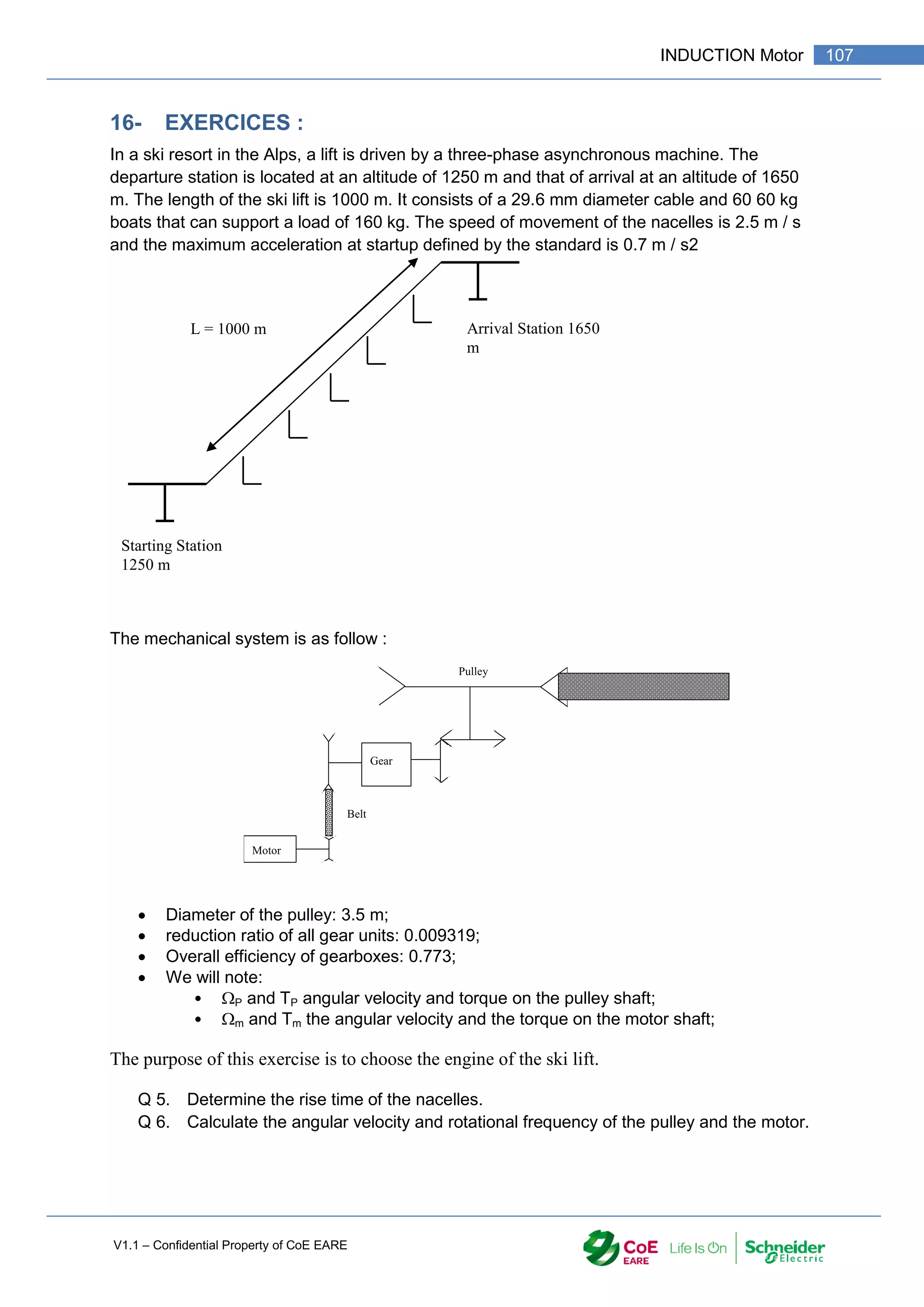

![V1.1 – Confidential Property of CoE EARE

108 [Industrial Automation – Part 1 Installation] [Safety and Security – Basic Industrial wiring]

Q 7. Knowing that the torque opposite the load on the pulley is 33 160 N.m in steady

state, calculate the resisting torque on the motor shaft.

Q 8. Deduce the mechanical power that must provide the engine in steady state.

Q 9. The maximum acceleration allowed for passenger transport is 0.7 m / s2. Calculate

the angular acceleration (d/dt) on the pulley shaft and then on the motor shaft.

Q 10. Knowing that the total moment of inertia of the system brought back on the motor

shaft is 9.16 kg.m2, calculate the accelerating torque necessary to meet the

specifications. Deduce the minimum starting torque of the machine. Calculate then

ratio Cd / Cn.

Q 11. The maximum temperature of the room in which the motor is located is 30 ° C.

Check if corrections are needed for the choice of engine.

Q 12. Using the above calculations, knowing that the power supply is three-phase 3 *

400 V 50 Hz, select the motor in the LEROY SOMER documents.

Q 13. Give the nameplate of this engine.

Q 14. What should be the coupling of the windings?

Q 15. Calculate the starting current of the motor. What precautions should be taken?

Q 16. Give the maximum value of the torque and its value at startup.

Q 17. Give the outside dimensions of the engine.