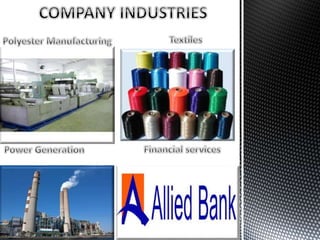

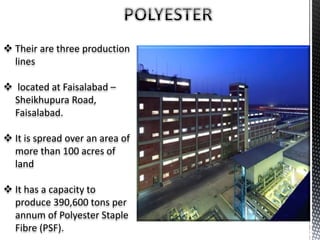

Ibrahim Fibres Limited is a public limited company incorporated in Pakistan that manufactures and sells polyester staple fibre and yarn. It has three production lines located on over 100 acres in Faisalabad with a capacity to produce 390,600 tons of polyester staple fibre annually. The company consistently upgrades its facilities with world-class technologies to maintain its position as a market leader. It also operates two power generation plants with a total capacity of 73.3 MW.