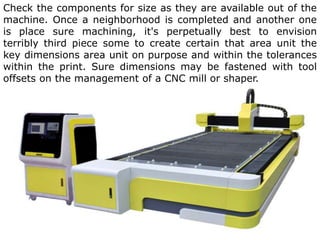

A CNC mill operator is responsible for ensuring components are machined within specifications. By keeping tools and the machine clean, making adjustments for worn tools, and checking dimensions of output parts, the operator can help prevent issues like breakage and ensure quality production. Regular maintenance, monitoring for overloads, and inspecting sample parts are important responsibilities for maintaining efficient operation of CNC milling machines.