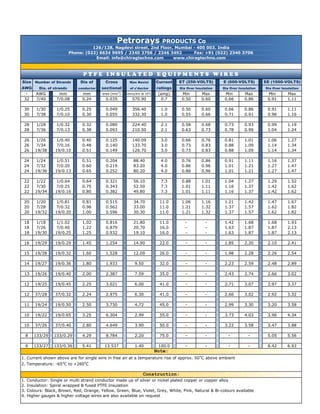

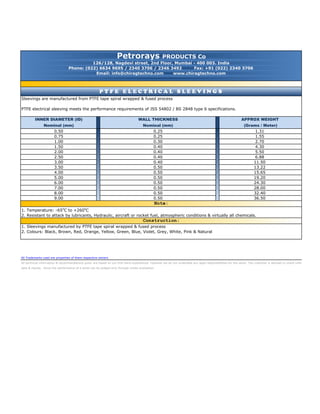

The document provides detailed specifications and product information for PTFE insulated equipment wires, electrical sleeving, and multi-core cables produced by Petrorays Products Co. It outlines various wire gauges, electrical characteristics, construction details, and insulation materials, emphasizing their resistance to chemicals and high-temperature ranges. Additionally, it includes contact information for the company and notes on performance evaluation responsibilities.