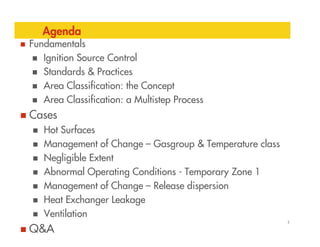

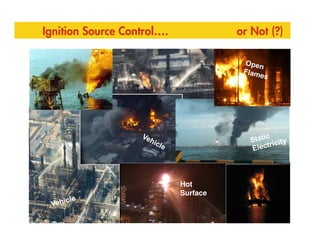

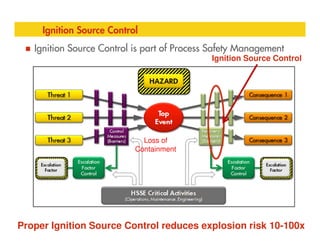

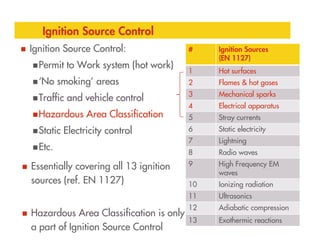

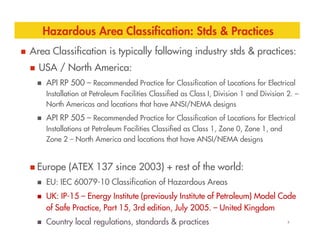

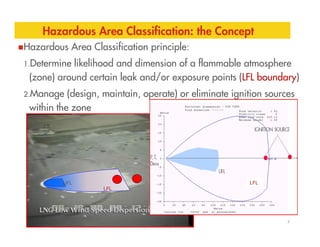

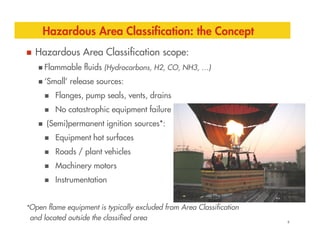

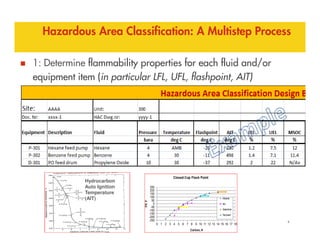

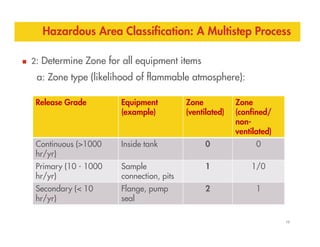

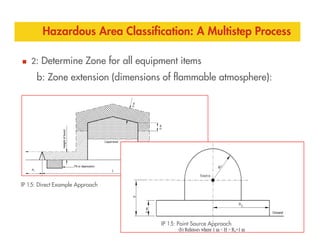

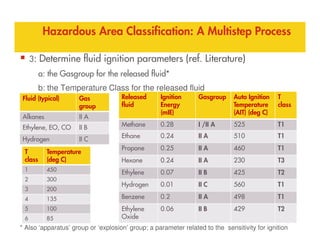

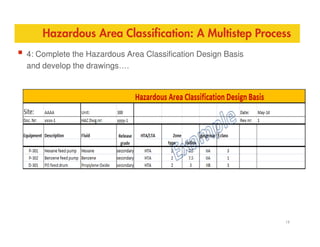

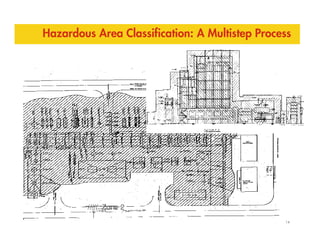

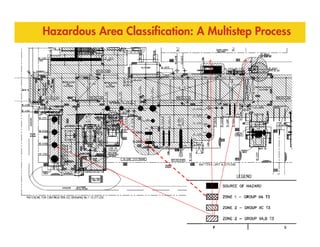

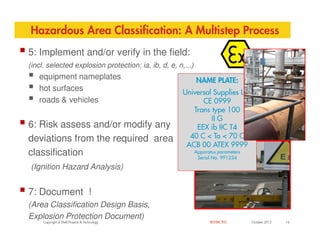

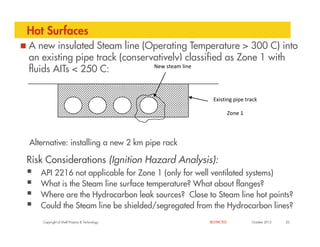

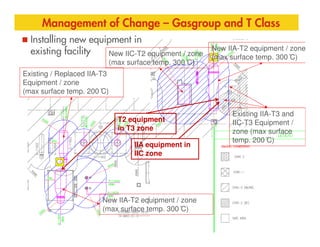

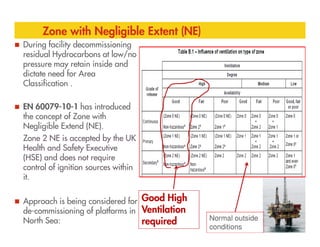

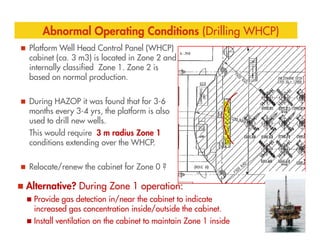

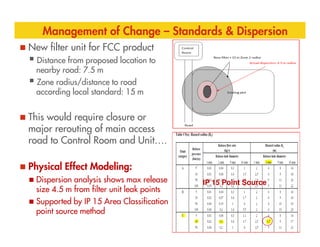

The document discusses hazardous area classification fundamentals and practices presented by Erik van de Kuilen at the ATEX congress in May 2014. It emphasizes the importance of ignition source control as part of process safety management and outlines a multistep process for area classification, detailing standards from various regions including the U.S. and Europe. Additionally, it covers case studies addressing challenges in managing ignition sources and the effects of operational changes on hazard classifications.