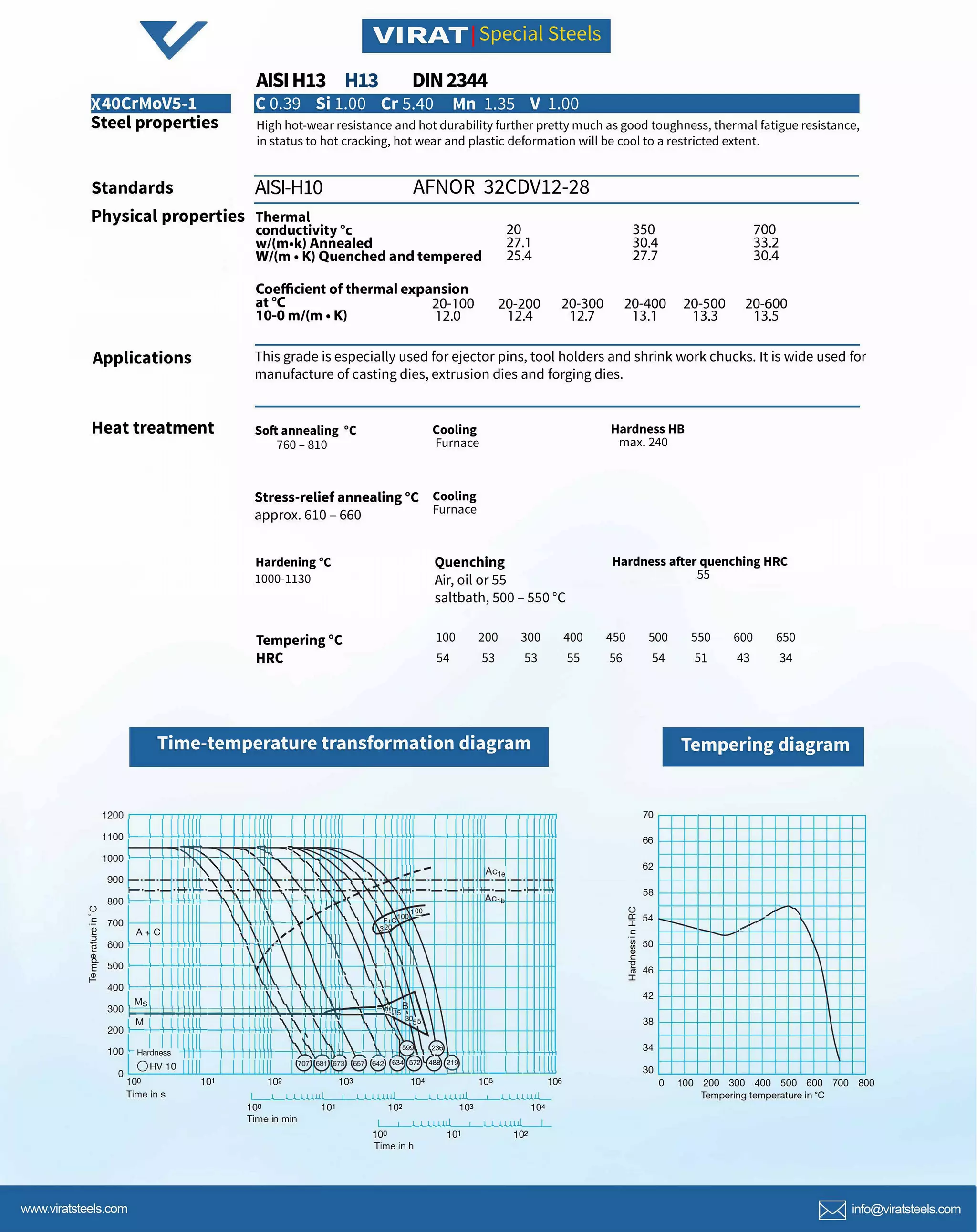

The document provides detailed specifications and properties of special steels, particularly AISI H13, noting its high resistance to hot wear and good toughness. It outlines the physical properties, applications, heat treatment processes, and hardness ratings relevant to manufacturing processes such as casting and forging. The data includes thermal conductivity, coefficient of thermal expansion, and tempering temperatures, emphasizing its suitability for use in ejector pins and tooling.