1) The document summarizes a presentation given at the North Carolina Federal Advanced Technologies Symposium on May 9, 2013.

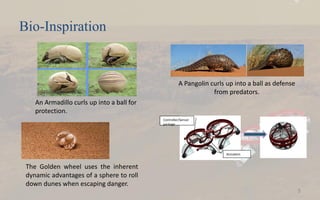

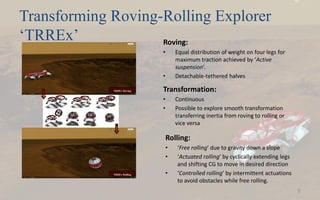

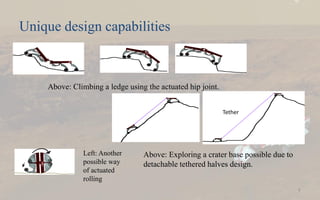

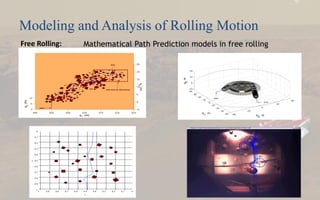

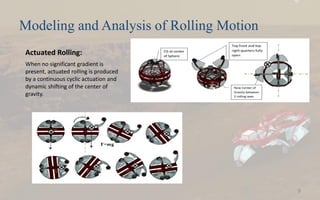

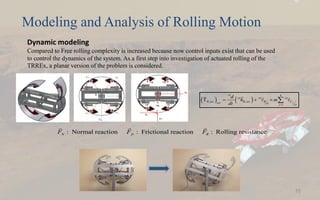

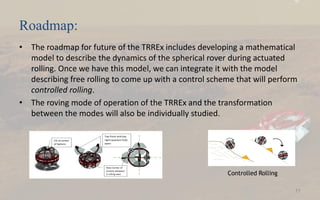

2) It describes a transforming rover called TRREx being developed at NC State University that can both rove and roll over terrain, drawing inspiration from armadillos and other ball-curling animals.

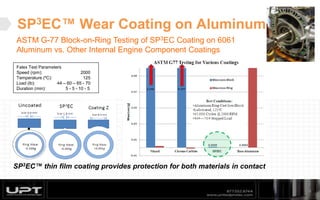

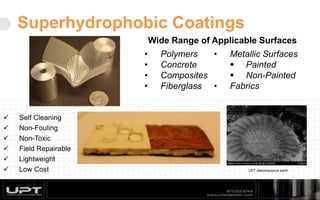

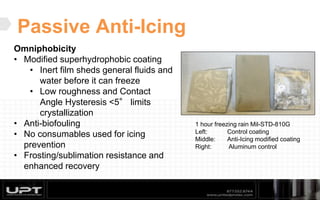

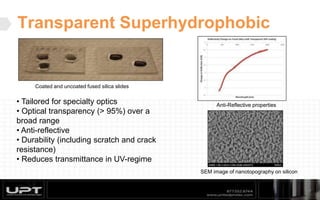

3) It then discusses various protective coatings for vehicles and robotics presented by Peter Venema, including wear-resistant, self-cleaning superhydrophobic, and anti-icing coatings.