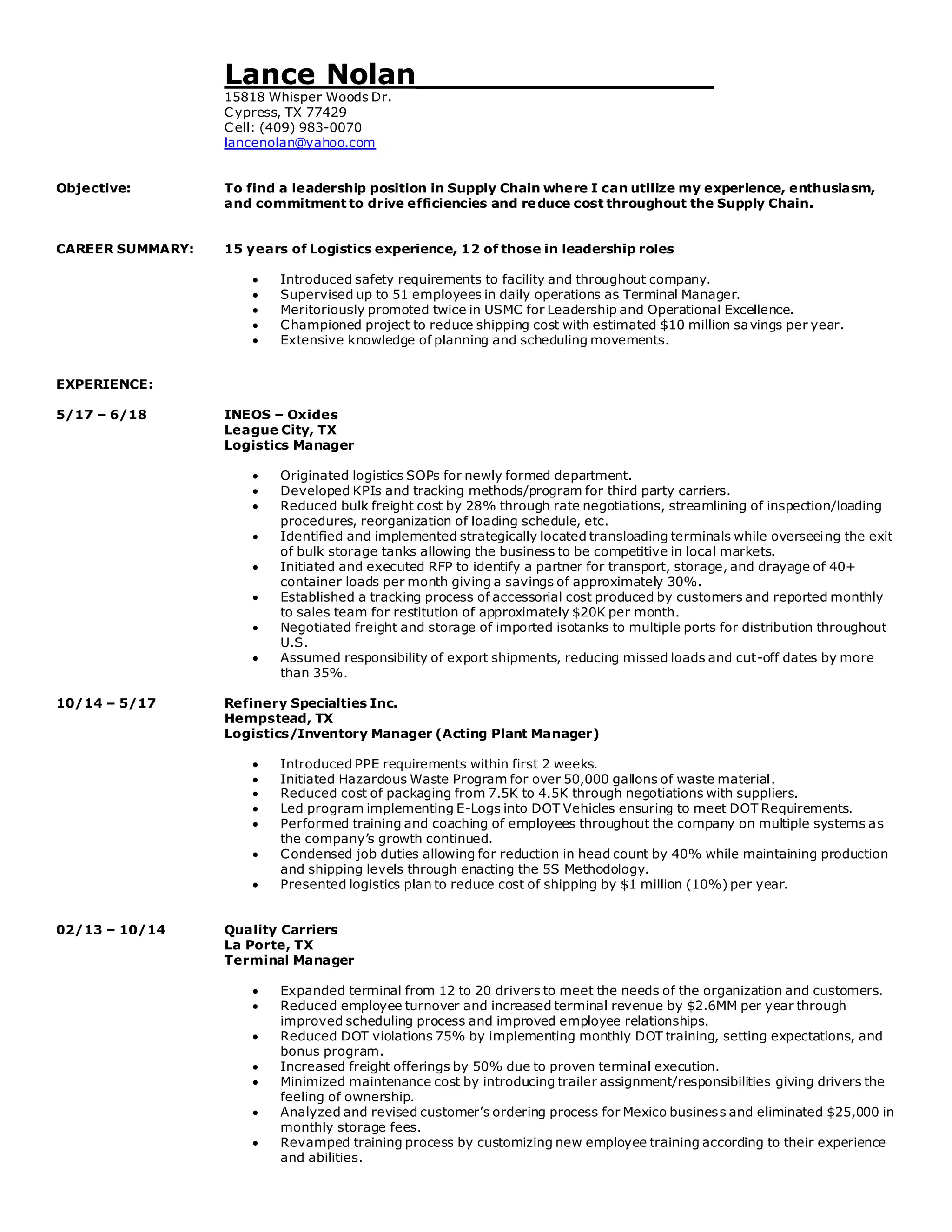

Lance Nolan has over 15 years of experience in logistics and supply chain leadership roles. He has a proven track record of driving cost efficiencies and process improvements. As Logistics Manager at INEOS, he reduced bulk freight costs by 28% and identified transloading terminals that allowed the business to be more competitive. Previously as Logistics/Inventory Manager at Refinery Specialties, he introduced new safety programs and reduced packaging costs. Nolan holds a Bachelor's degree in Industrial Technology and is seeking a new leadership opportunity in supply chain.