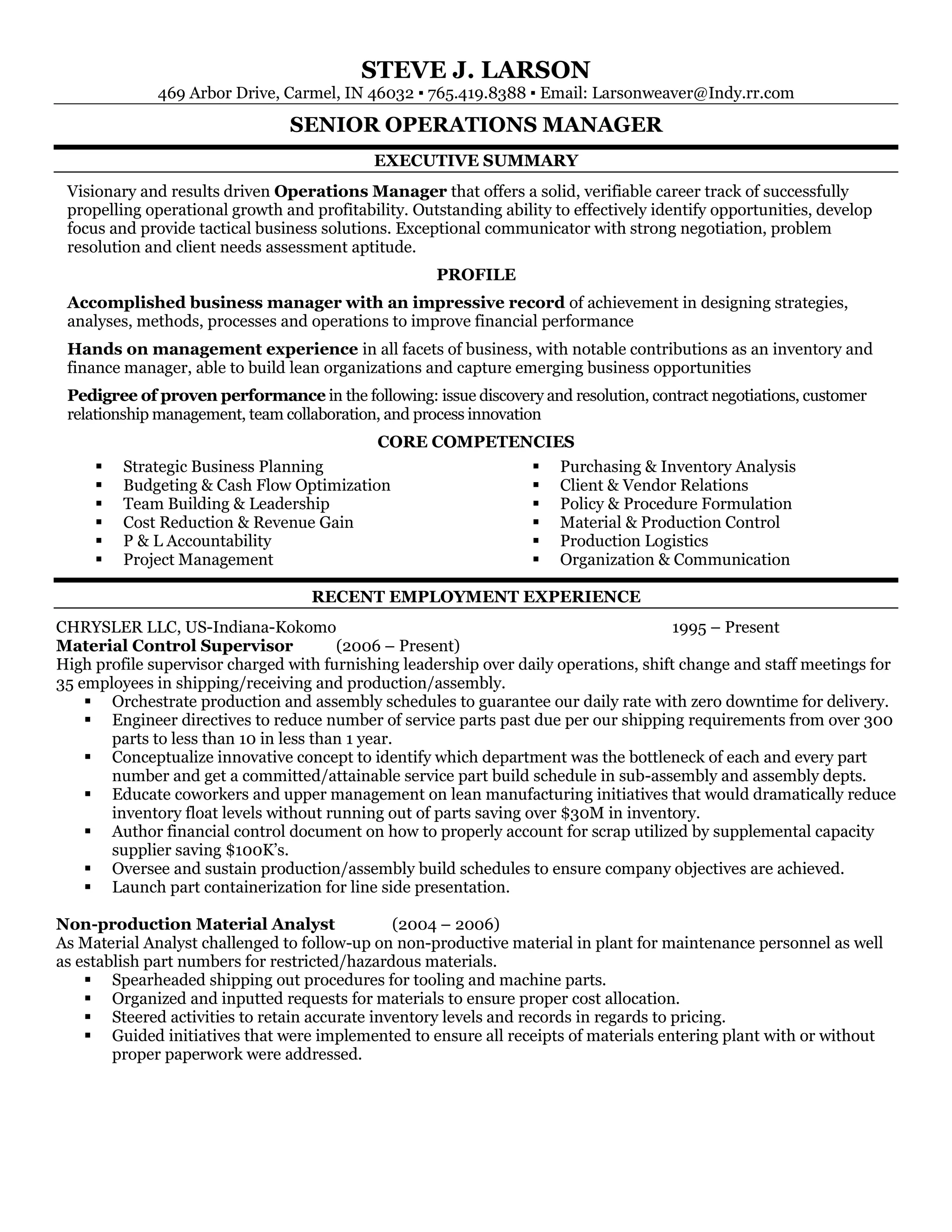

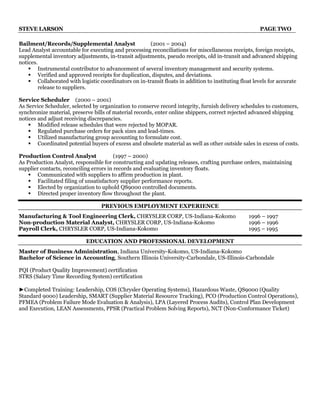

Steve Larson has over 20 years of experience in operations management at Chrysler LLC, where he has held several roles of increasing responsibility. He has a strong track record of improving operational efficiency and reducing costs. Larson has expertise in strategic planning, budgeting, inventory analysis, and process improvement. He aims to identify opportunities to propel growth and profitability through effective leadership.