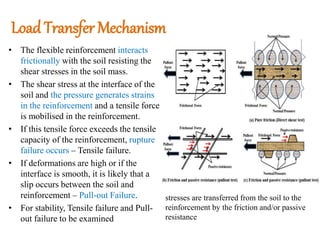

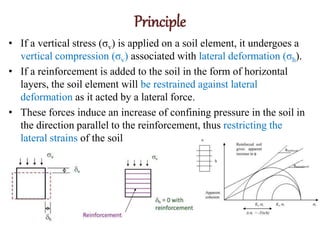

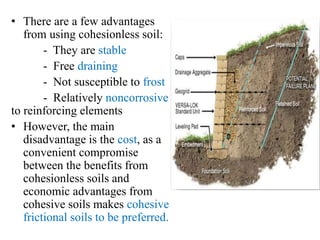

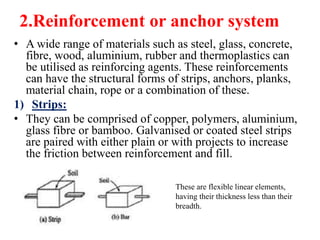

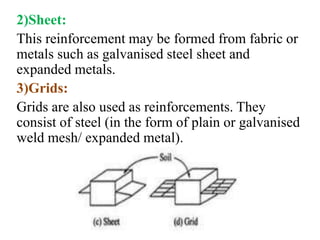

The document describes how soil reinforcement works. Tensile elements are placed in the soil to improve its strength and stability. When pressure is applied, it causes strain on the reinforcement elements, creating tensile loads that resist soil movement. This provides greater shear strength than soil alone. The reinforcement interacts frictionally with the soil to resist shear stresses, transferring loads from the soil. If tensile or pull-out failures occur, the stability is examined. Common reinforcement materials include strips, sheets, grids and geosynthetics made of polymers, steel or natural materials.