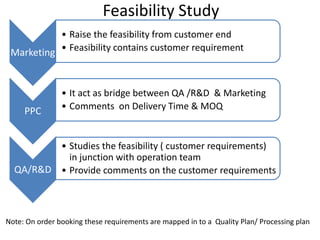

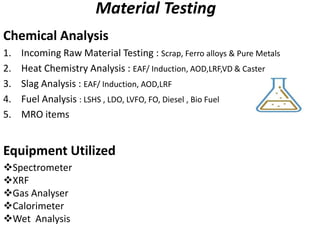

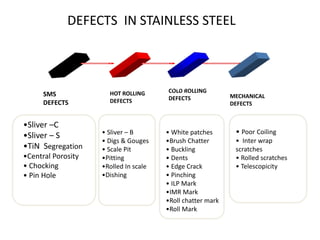

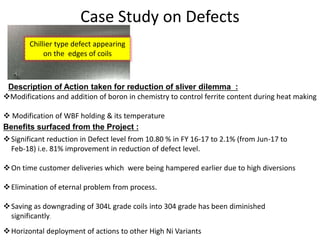

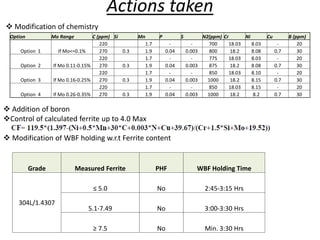

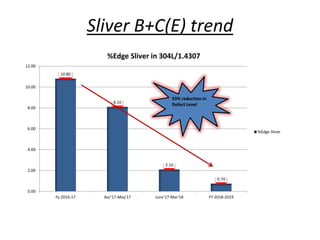

This document discusses quality assurance processes and defect analysis for stainless steel production. It covers feasibility studies, material testing including chemical analysis and mechanical testing, certifications, common defects at different production stages, and a case study on reducing sliver defects through chemistry and process modifications. The key quality assurance areas discussed are inspection, testing, process control, analysis of defects and improvements.