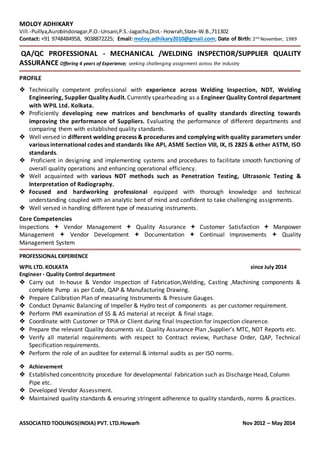

Moloy Adhikary is a QA/QC professional with over 4 years of experience in welding inspection, NDT, supplier quality assurance, and quality control. He is currently an Engineer in the Quality Control department at WPIL Ltd. in Kolkata. Some of his responsibilities include conducting in-house and vendor inspections, preparing calibration plans, performing NDT examinations, and ensuring adherence to quality standards. Previously he has worked as an Engineer in quality control/assurance at Associated Toolings and as an Executive in quality assurance at Viraj Profiles. He holds a Diploma in Mechanical Engineering and is proficient in ERP systems, MS Office, and various quality standards.