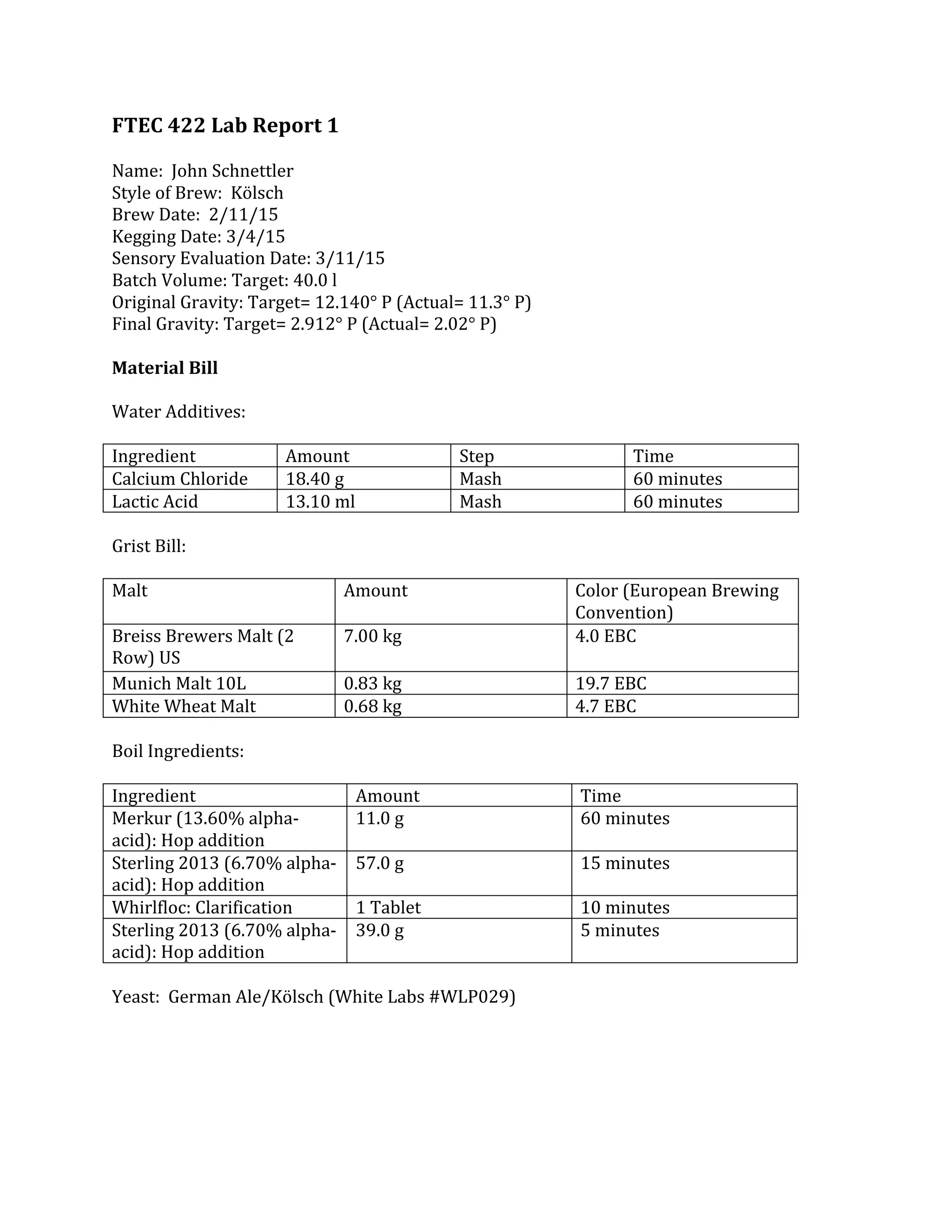

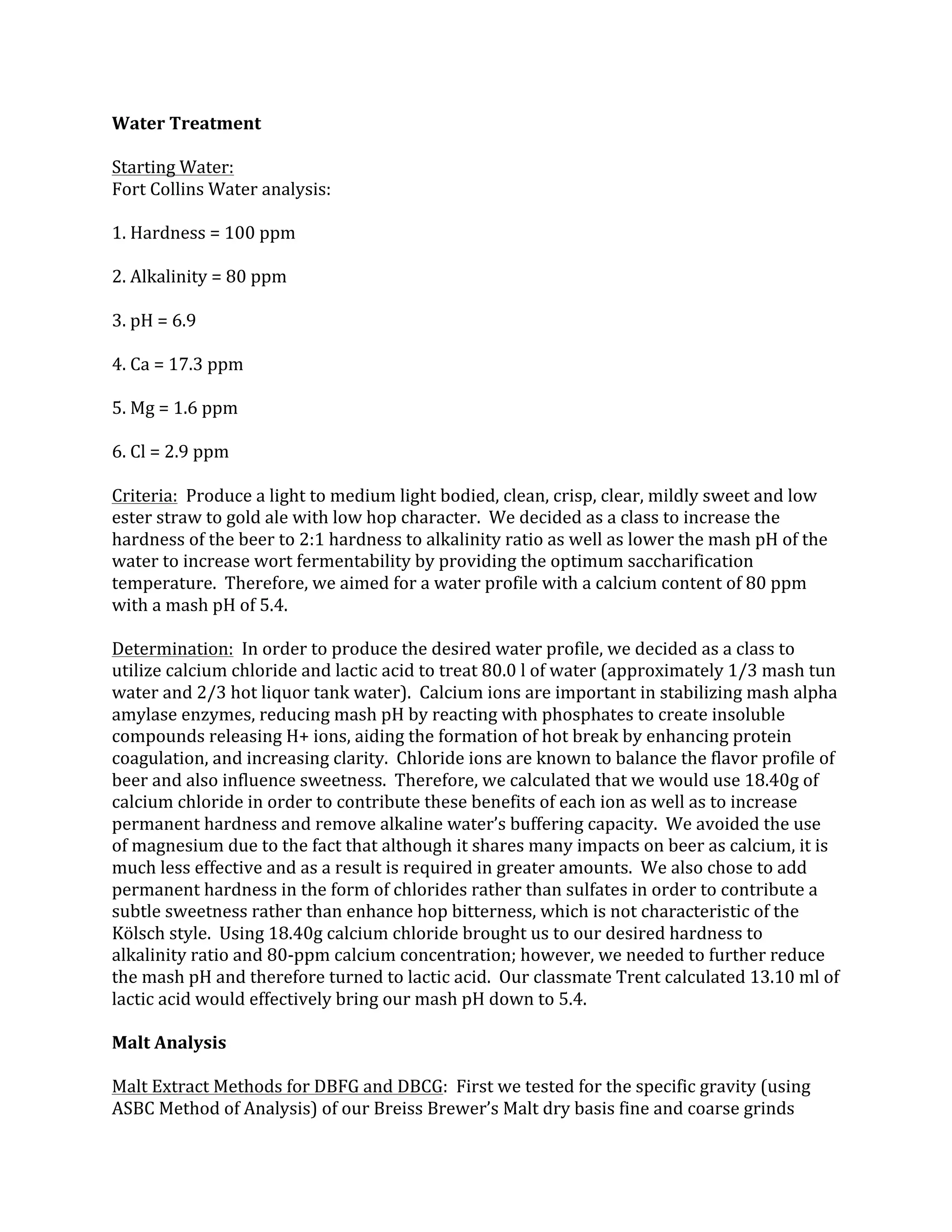

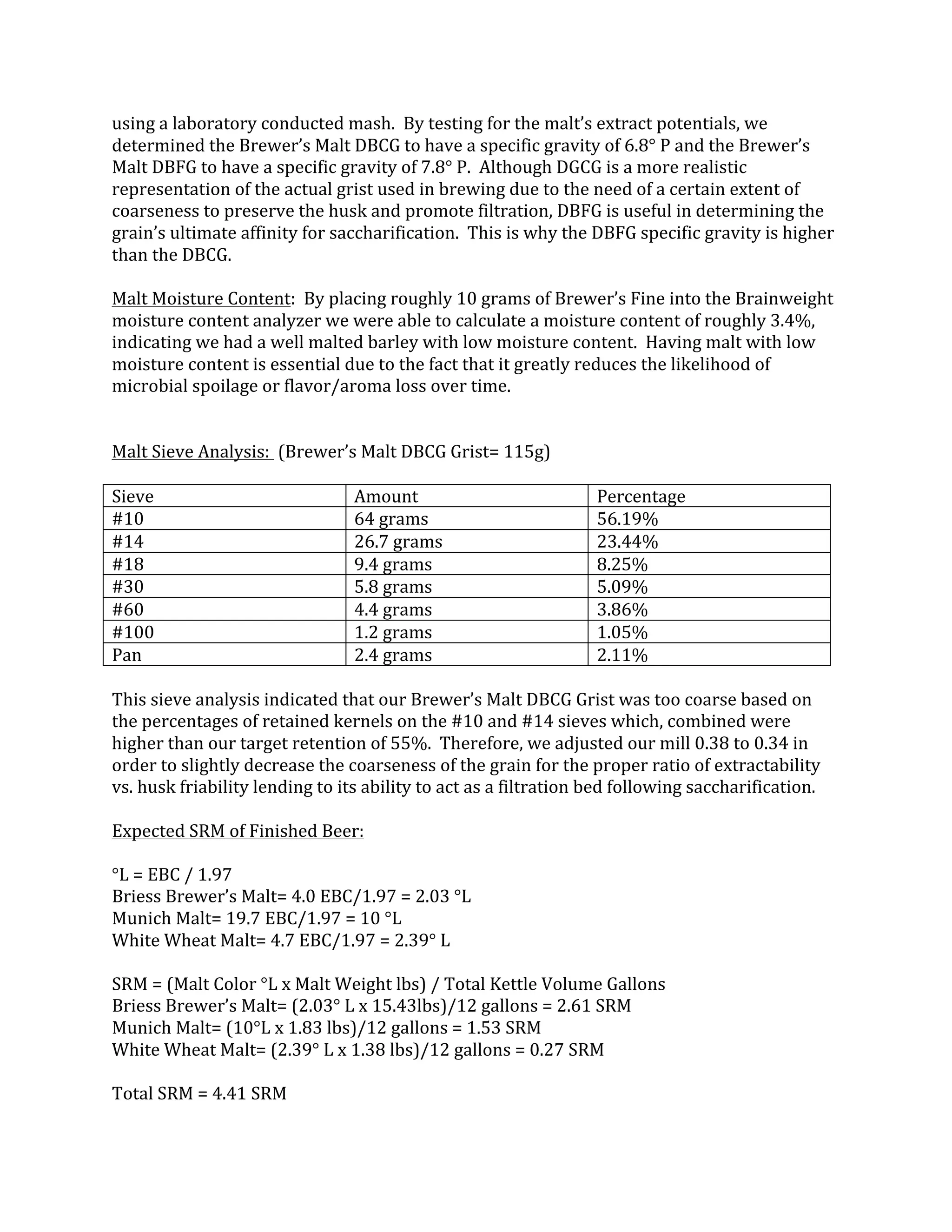

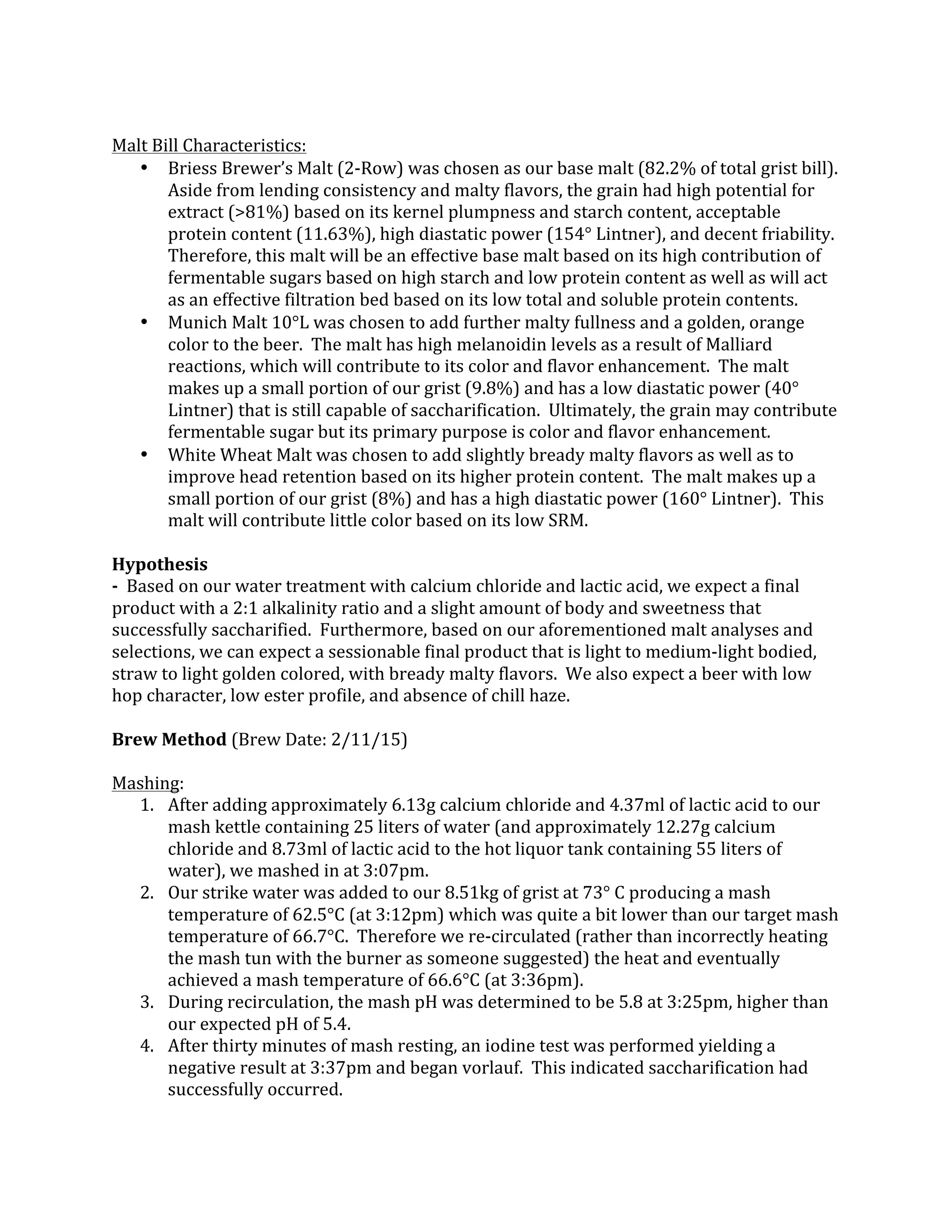

This document summarizes John Schnettler's brewing of a Kölsch style beer. It includes details of the materials used such as water chemistry adjustments with calcium chloride and lactic acid, and a grist bill of Pilsner malt, Munich malt, and wheat malt. Yeast used was WLP029 German Ale/Kölsch. The document also analyzes the malt extract potential and moisture content. Sensory evaluation was planned for March 11th after kegging on March 4th.