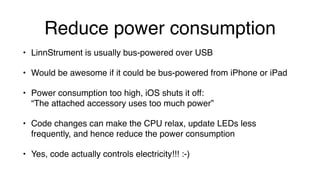

Geert Bevin, a software engineer and musician, presents insights into the LinnStrument, a revolutionary music performance controller that utilizes Arduino technology for advanced touch sensitivity. The document elaborates on hardware components, firmware examples, and coding techniques, demonstrating how to manage LED and touch sensor functionalities while maintaining performance and power efficiency. Key concepts include the use of Arduino for communication protocols, the design of a touch-sensitive interface, and strategies for optimizing both functionality and power consumption.

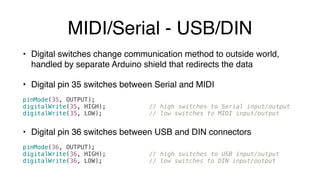

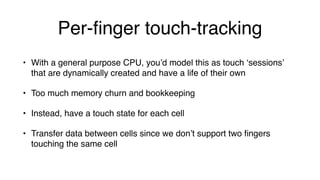

![Global Variables

• Master of the whole machine, global is good!

• Some examples of variables:

byte sensorCol; // column number of the current sensor

byte sensorRow; // row number of the current sensor

byte sensorSplit; // split of the current sensor

TouchInfo* sensorCell; // all touch data of current sensor

TouchInfo touchInfo[MAXCOLS][MAXROWS]; // grid with all touch data

struct Configuration config; // entry-point towards all the settings

DisplayMode displayMode; // the active display mode](https://image.slidesharecdn.com/fromarduinotolinnstrument-170612082844/85/From-Arduino-to-LinnStrument-33-320.jpg)

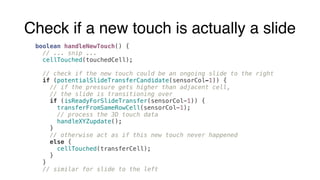

![Check potential slide transfer

boolean potentialSlideTransferCandidate(int col) {

// ... snip ...

if (col < 1) return false;

if (sensorSplit != getSplitOf(col)) return false;

if (!isLowRow() && (!Split[sensorSplit].sendX ||

!isFocusedCell(col, sensorRow))) return false;

if (isLowRow() && !lowRowRequiresSlideTracking()) return false;

// ... snip ...

// the sibling cell has an active touch

return cell(col, sensorRow).touched != untouchedCell &&

// either a release is pending to be performed, or

(cell(col, sensorRow).pendingReleaseCount ||

// both cells are touched simultaneously on the edges

abs(cell().calibratedX() - cell(col, sensorRow).calibratedX())

< TRANSFER_SLIDE_PROXIMITY);

}](https://image.slidesharecdn.com/fromarduinotolinnstrument-170612082844/85/From-Arduino-to-LinnStrument-40-320.jpg)

![Low-row functions 1/2

void lowRowStart() {

switch (Split[sensorSplit].lowRowMode) {

case lowRowStrum:

lowRowState[sensorCol] = pressed;

break;

// ... snip, different for each low-row mode

}

}

void lowRowStop() {

switch (Split[sensorSplit].lowRowMode) {

case lowRowStrum:

lowRowState[sensorCol] = inactive;

break;

// ... snip, different for each low-row mode

}

}](https://image.slidesharecdn.com/fromarduinotolinnstrument-170612082844/85/From-Arduino-to-LinnStrument-48-320.jpg)

![Low-row functions 2/2

void handleLowRowState(boolean newVelocity, short pitchBend,

short timbre, byte pressure) {

// this is a low-row cell

if (isLowRow()) {

// ... snip, send out the continuous data for low-row cells

}

// this is a non low-row cell

else {

switch (Split[sensorSplit].lowRowMode) {

case lowRowStrum:

// uses lowRowState to correlate with column

handleLowRowStrum();

break;

// ... snip, other cases

}

}

}](https://image.slidesharecdn.com/fromarduinotolinnstrument-170612082844/85/From-Arduino-to-LinnStrument-49-320.jpg)

![Only light LEDs half of the time

void refreshLedColumn(unsigned long now) {

static byte displayInterval[MAXCOLS][MAXROWS];

// ... snip ...

for (byte rowCount = 0; rowCount < NUMROWS; ++rowCount) {

if (++displayInterval[actualCol][rowCount] >= 12) {

displayInterval[actualCol][rowCount] = 0;

}

// ... snip ...

if (Device.operatingLowPower) {

if (displayInterval[actualCol][rowCount] % 2 != 0) {

cellDisplay = cellOff;

}

}

// ... snip ...

}

}](https://image.slidesharecdn.com/fromarduinotolinnstrument-170612082844/85/From-Arduino-to-LinnStrument-54-320.jpg)