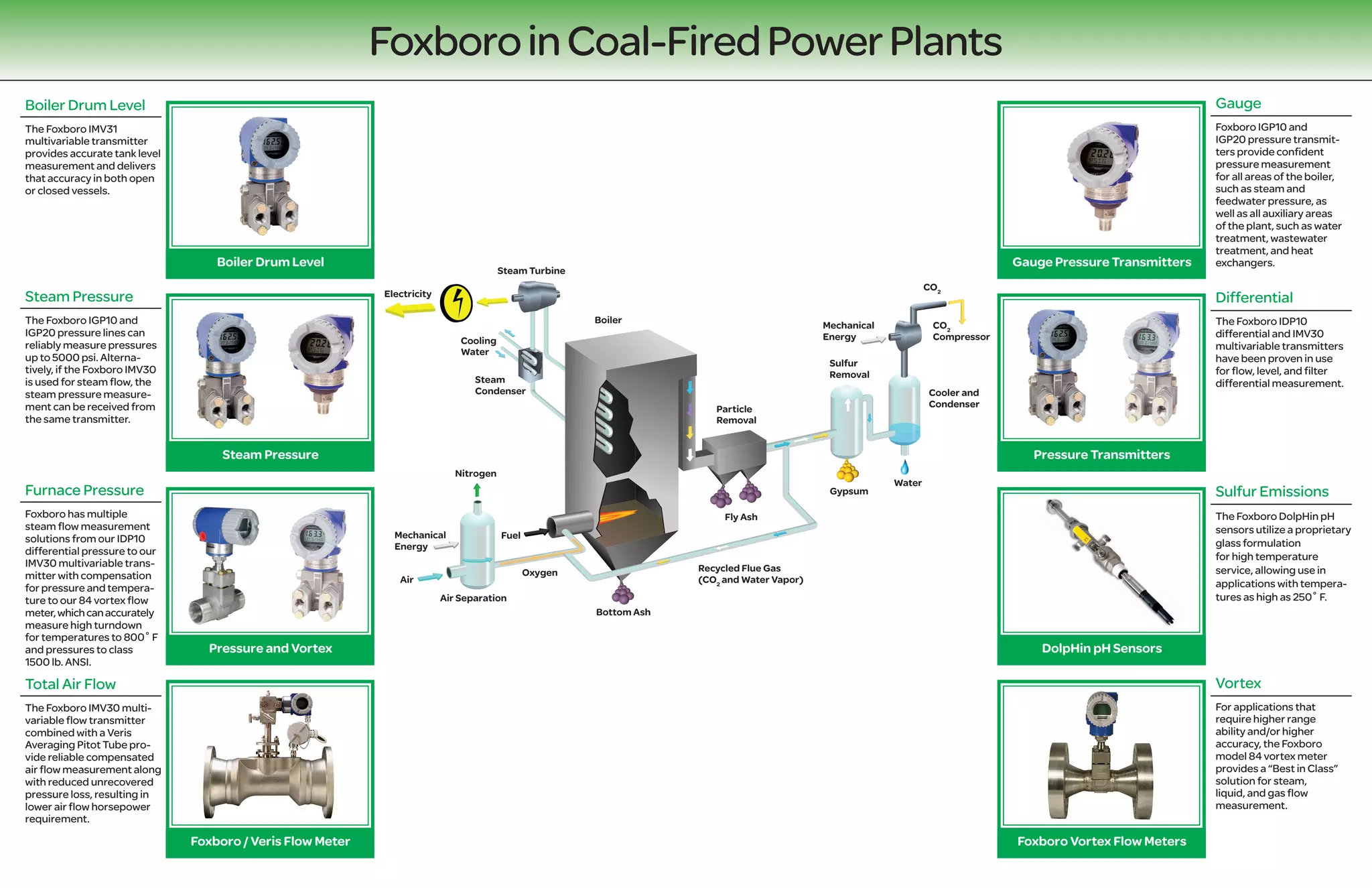

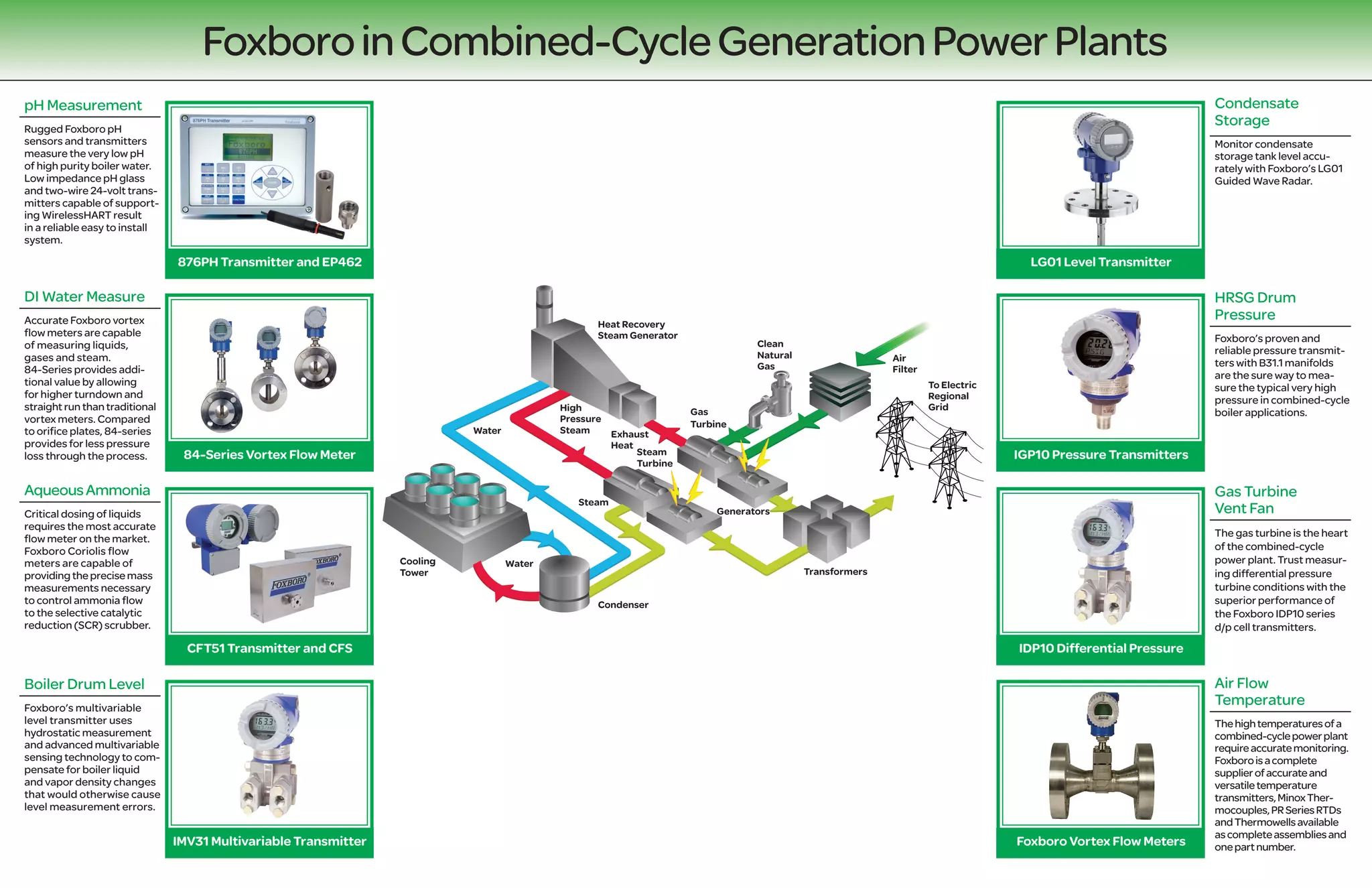

Foxboro has over 100 years of experience providing automation solutions for the power generation industry, particularly focusing on coal-fired and combined-cycle power plants. Their advanced instrumentation includes pressure and temperature transmitters, flow meters, and pH sensors, designed for improved economic, safety, and environmental performance. Collaborating with industry leaders, Foxboro supports the operational demands of modern power plants, enhancing asset utilization and efficiency.