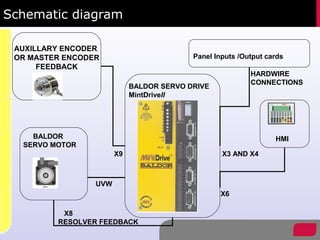

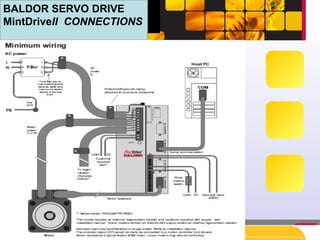

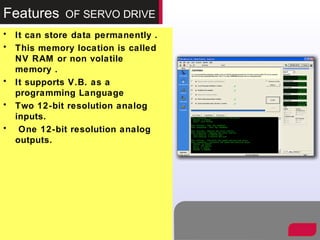

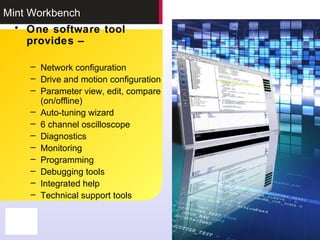

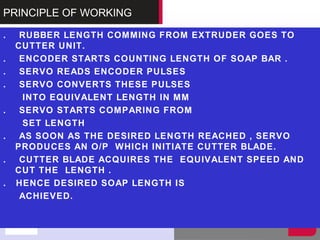

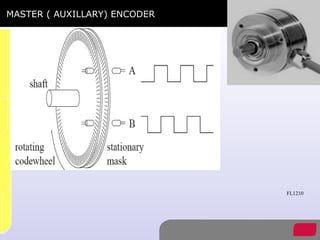

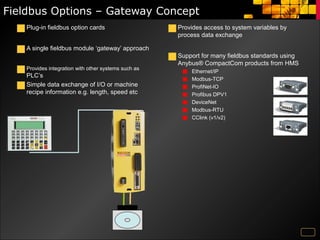

This document provides information about a Kudamm Corporation flying shear linear cutting system that uses a Baldor servo motor and MintDriveII servo drive. It includes a schematic diagram of the system components and connections. It also describes features of the servo drive like non-volatile memory and analog inputs/outputs. Additional sections cover the Mint Workbench software, principle of operation where the servo controls the cutter based on encoder feedback, and fieldbus integration options for the drive.