This document is the theory guide for ANSYS FLUENT 12.0. It provides an overview of the physical models available in FLUENT for various fluid flow situations, such as basic fluid flow, flows with rotating reference frames, flows using sliding and deforming meshes, turbulence modeling, heat transfer, and other topics. The guide describes the governing equations and assumptions underlying each model. It is intended to help users understand the theoretical basis of the simulations that can be performed with FLUENT.

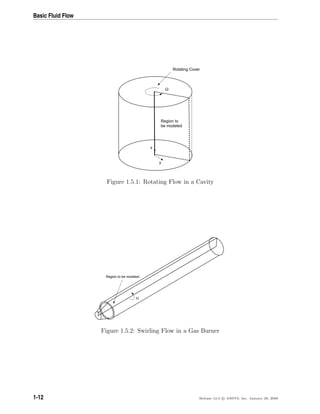

![Basic Fluid Flow

Momentum Conservation Equations

Conservation of momentum in an inertial (non-accelerating) reference frame is described

by [17]

∂

∂t

(ρv) + · (ρvv) = − p + · (τ) + ρg + F (1.2-3)

where p is the static pressure, τ is the stress tensor (described below), and ρg and F are

the gravitational body force and external body forces (e.g., that arise from interaction

with the dispersed phase), respectively. F also contains other model-dependent source

terms such as porous-media and user-defined sources.

The stress tensor τ is given by

τ = µ ( v + v T

) −

2

3

· vI (1.2-4)

where µ is the molecular viscosity, I is the unit tensor, and the second term on the right

hand side is the effect of volume dilation.

For 2D axisymmetric geometries, the axial and radial momentum conservation equations

are given by

∂

∂t

(ρvx) +

1

r

∂

∂x

(rρvxvx) +

1

r

∂

∂r

(rρvrvx) = −

∂p

∂x

+

1

r

∂

∂x

rµ 2

∂vx

∂x

−

2

3

( · v)

+

1

r

∂

∂r

rµ

∂vx

∂r

+

∂vr

∂x

+ Fx

(1.2-5)

and

∂

∂t

(ρvr) +

1

r

∂

∂x

(rρvxvr) +

1

r

∂

∂r

(rρvrvr) = −

∂p

∂r

+

1

r

∂

∂x

rµ

∂vr

∂x

+

∂vx

∂r

+

1

r

∂

∂r

rµ 2

∂vr

∂r

−

2

3

( · v) − 2µ

vr

r2

+

2

3

µ

r

( · v) + ρ

v2

z

r

+ Fr (1.2-6)

where

· v =

∂vx

∂x

+

∂vr

∂r

+

vr

r

(1.2-7)

and vz is the swirl velocity. (See Section 1.5: Swirling and Rotating Flows for information

about modeling axisymmetric swirl.)

1-4 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-28-320.jpg)

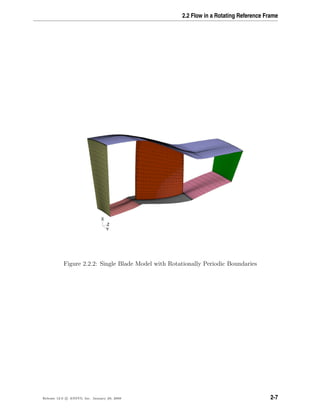

![Flows with Rotating Reference Frames

Figure 2.2.1: Stationary and Rotating Reference Frames

In the above, vr is the relative velocity (the velocity viewed from the rotating frame), v

is the absolute velocity (the velocity viewed from the stationary frame), and ur is the

“whirl” velocity (the velocity due to the moving frame).

When the equations of motion are solved in the rotating reference frame, the accel-

eration of the fluid is augmented by additional terms that appear in the momentum

equations [17]. Moreover, the equations can be formulated in two different ways:

• Expressing the momentum equations using the relative velocities as dependent vari-

ables (known as the relative velocity formulation).

• Expressing the momentum equations using the absolute velocities as dependent

variables in the momentum equations (known as the absolute velocity formulation).

The exact forms of the governing equations for these two formulations will be provided

in the sections below. It can be noted here that ANSYS FLUENT’s pressure-based solvers

provide the option to use either of these two formulations, whereas the density-based

solvers always use the absolute velocity formulation. For more information about the

advantages of each velocity formulation, see Section 10.7.1: Choosing the Relative or

Absolute Velocity Formulation (in the separate User’s Guide).

2-4 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-50-320.jpg)

![Flows with Rotating Reference Frames

2.3 Flow in Multiple Rotating Reference Frames

Many problems involve multiple moving parts or contain stationary surfaces which are

not surfaces of revolution (and therefore cannot be used with the Single Reference Frame

modeling approach). For these problems, you must break up the model into multiple

fluid/solid cell zones, with interface boundaries separating the zones. Zones which contain

the moving components can then be solved using the moving reference frame equations

(Section 2.2.1: Equations for a Rotating Reference Frame), whereas stationary zones can

be solved with the stationary frame equations. The manner in which the equations are

treated at the interface lead to two approaches which are supported in ANSYS FLUENT:

• Multiple Rotating Reference Frames

– Multiple Reference Frame model (MRF) (see Section 2.3.1: The Multiple Ref-

erence Frame Model)

– Mixing Plane Model (MPM) (see Section 2.3.2: The Mixing Plane Model)

• Sliding Mesh Model (SMM)

Both the MRF and mixing plane approaches are steady-state approximations, and differ

primarily in the manner in which conditions at the interfaces are treated. These ap-

proaches will be discussed in the sections below. The sliding mesh model approach is,

on the other hand, inherently unsteady due to the motion of the mesh with time. This

approach is discussed in Chapter 3: Flows Using Sliding and Deforming Meshes.

2.3.1 The Multiple Reference Frame Model

Overview

The MRF model [209] is, perhaps, the simplest of the two approaches for multiple zones.

It is a steady-state approximation in which individual cell zones can be assigned different

rotational and/or translational speeds. The flow in each moving cell zone is solved using

the moving reference frame equations (see Section 2.2: Flow in a Rotating Reference

Frame). If the zone is stationary (ω = 0), the equations reduce to their stationary forms.

At the interfaces between cell zones, a local reference frame transformation is performed

to enable flow variables in one zone to be used to calculate fluxes at the boundary of

the adjacent zone. The MRF interface formulation will be discussed in more detail in

Section 2.3.1: The MRF Interface Formulation.

It should be noted that the MRF approach does not account for the relative motion of

a moving zone with respect to adjacent zones (which may be moving or stationary); the

mesh remains fixed for the computation. This is analogous to freezing the motion of the

moving part in a specific position and observing the instantaneous flowfield with the rotor

in that position. Hence, the MRF is often referred to as the “frozen rotor approach.”

2-8 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-54-320.jpg)

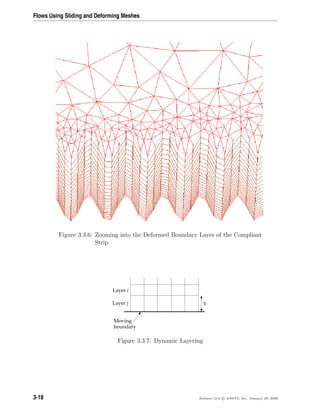

![Flows Using Sliding and Deforming Meshes

In the case of the sliding mesh, the motion of moving zones is tracked relative to the

stationary frame. Therefore, no moving reference frames are attached to the computa-

tional domain, simplifying the flux transfers across the interfaces. In the sliding mesh

formulation, the control volume remains constant, therefore from Equation 3.1-3, dV

dt

= 0

and V n+1

= V n

. Equation 3.1-2 can now be expressed as follows:

d

dt V

ρφdV =

[(ρφ)n+1

− (ρφ)n

]V

∆t

(3.1-6)

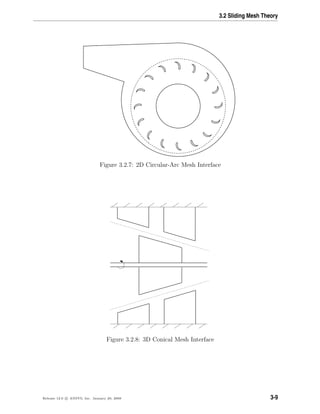

3.2 Sliding Mesh Theory

When a time-accurate solution for rotor-stator interaction (rather than a time-averaged

solution) is desired, you must use the sliding mesh model to compute the unsteady flow

field. As mentioned in Section 2.1: Introduction, the sliding mesh model is the most

accurate method for simulating flows in multiple moving reference frames, but also the

most computationally demanding.

Most often, the unsteady solution that is sought in a sliding mesh simulation is time-

periodic. That is, the unsteady solution repeats with a period related to the speeds of the

moving domains. However, you can model other types of transients, including translating

sliding mesh zones (e.g., two cars or trains passing in a tunnel, as shown in Figure 3.2.1).

Interface

Figure 3.2.1: Two Passing Trains in a Tunnel

3-4 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-72-320.jpg)

![Flows Using Sliding and Deforming Meshes

• rotation about the x-axis (e.g., roll for airplanes)

• rotation about the y-axis (e.g., pitch for airplanes)

• rotation about the z-axis (e.g., yaw for airplanes)

Once the angular and the translational accelerations are computed from Equation 3.3-17

and Equation 3.3-18, the rates are derived by numerical integration [328]. The angular

and translational velocities are used in the dynamic mesh calculations to update the rigid

body position.

3-32 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-100-320.jpg)

![4.2 Choosing a Turbulence Model

∂ρ

∂t

+

∂

∂xi

(ρui) = 0 (4.2-3)

∂

∂t

(ρui)+

∂

∂xj

(ρuiuj) = −

∂p

∂xi

+

∂

∂xj

µ

∂ui

∂xj

+

∂uj

∂xi

−

2

3

δij

∂ul

∂xl

+

∂

∂xj

(−ρuiuj) (4.2-4)

Equations 4.2-3 and 4.2-4 are called Reynolds-averaged Navier-Stokes (RANS) equations.

They have the same general form as the instantaneous Navier-Stokes equations, with

the velocities and other solution variables now representing ensemble-averaged (or time-

averaged) values. Additional terms now appear that represent the effects of turbulence.

These Reynolds stresses, −ρuiuj, must be modeled in order to close Equation 4.2-4.

For variable-density flows, Equations 4.2-3 and 4.2-4 can be interpreted as Favre-averaged

Navier-Stokes equations [130], with the velocities representing mass-averaged values. As

such, Equations 4.2-3 and 4.2-4 can be applied to density-varying flows.

4.2.3 Boussinesq Approach vs. Reynolds Stress Transport Models

The Reynolds-averaged approach to turbulence modeling requires that the Reynolds

stresses in Equation 4.2-4 are appropriately modeled. A common method employs the

Boussinesq hypothesis [130] to relate the Reynolds stresses to the mean velocity gradients:

− ρuiuj = µt

∂ui

∂xj

+

∂uj

∂xi

−

2

3

ρk + µt

∂uk

∂xk

δij (4.2-5)

The Boussinesq hypothesis is used in the Spalart-Allmaras model, the k- models, and

the k-ω models. The advantage of this approach is the relatively low computational

cost associated with the computation of the turbulent viscosity, µt. In the case of the

Spalart-Allmaras model, only one additional transport equation (representing turbulent

viscosity) is solved. In the case of the k- and k-ω models, two additional transport

equations (for the turbulence kinetic energy, k, and either the turbulence dissipation

rate, , or the specific dissipation rate, ω) are solved, and µt is computed as a function of

k and or k and ω. The disadvantage of the Boussinesq hypothesis as presented is that

it assumes µt is an isotropic scalar quantity, which is not strictly true.

The alternative approach, embodied in the RSM, is to solve transport equations for each

of the terms in the Reynolds stress tensor. An additional scale-determining equation

(normally for ) is also required. This means that five additional transport equations are

required in 2D flows and seven additional transport equations must be solved in 3D.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-5](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-105-320.jpg)

![4.3 Spalart-Allmaras Model

In its original form, the Spalart-Allmaras model is effectively a low-Reynolds-number

model, requiring the viscosity-affected region of the boundary layer to be properly re-

solved. In ANSYS FLUENT, however, the Spalart-Allmaras model has been implemented

to use wall functions when the mesh resolution is not sufficiently fine. This might make

it the best choice for relatively crude simulations on coarse meshes where accurate tur-

bulent flow computations are not critical. Furthermore, the near-wall gradients of the

transported variable in the model are much smaller than the gradients of the transported

variables in the k- or k-ω models. This might make the model less sensitive to numer-

ical errors when non-layered meshes are used near walls. See Section 6.1.3: Numerical

Diffusion in the separate User’s Guide for a further discussion of the numerical errors.

On a cautionary note, however, the Spalart-Allmaras model is still relatively new, and

no claim is made regarding its suitability to all types of complex engineering flows. For

instance, it cannot be relied on to predict the decay of homogeneous, isotropic turbu-

lence. Furthermore, one-equation models are often criticized for their inability to rapidly

accommodate changes in length scale, such as might be necessary when the flow changes

abruptly from a wall-bounded to a free shear flow.

In turbulence models that employ the Boussinesq approach, the central issue is how the

eddy viscosity is computed. The model proposed by Spalart and Allmaras [331] solves

a transport equation for a quantity that is a modified form of the turbulent kinematic

viscosity.

4.3.2 Transport Equation for the Spalart-Allmaras Model

The transported variable in the Spalart-Allmaras model, ν, is identical to the turbulent

kinematic viscosity except in the near-wall (viscosity-affected) region. The transport

equation for ν is

∂

∂t

(ρν)+

∂

∂xi

(ρνui) = Gν +

1

σν

∂

∂xj

(µ + ρν)

∂ν

∂xj

+ Cb2ρ

∂ν

∂xj

2

−Yν +Sν (4.3-1)

where Gν is the production of turbulent viscosity, and Yν is the destruction of turbulent

viscosity that occurs in the near-wall region due to wall blocking and viscous damping.

σν and Cb2 are the constants and ν is the molecular kinematic viscosity. Sν is a user-

defined source term. Note that since the turbulence kinetic energy, k, is not calculated

in the Spalart-Allmaras model, while the last term in Equation 4.2-5 is ignored when

estimating the Reynolds stresses.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-7](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-107-320.jpg)

![4.3 Spalart-Allmaras Model

The justification for the default expression for S is that, in the wall-bounded flows that

were of most interest when the model was formulated, the turbulence production found

only where vorticity is generated near walls. However, it has since been acknowledged that

one should also take into account the effect of mean strain on the turbulence production,

and a modification to the model has been proposed [65] and incorporated into ANSYS

FLUENT.

This modification combines the measures of both vorticity and the strain tensors in the

definition of S:

S ≡ |Ωij| + Cprod min (0, |Sij| − |Ωij|) (4.3-10)

where

Cprod = 2.0, |Ωij| ≡ 2ΩijΩij, |Sij| ≡ 2SijSij

with the mean strain rate, Sij, defined as

Sij =

1

2

∂uj

∂xi

+

∂ui

∂xj

(4.3-11)

Including both the rotation and strain tensors reduces the production of eddy viscosity

and consequently reduces the eddy viscosity itself in regions where the measure of vortic-

ity exceeds that of strain rate. One such example can be found in vortical flows, i.e., flow

near the core of a vortex subjected to a pure rotation where turbulence is known to be

suppressed. Including both the rotation and strain tensors more correctly accounts for

the effects of rotation on turbulence. The default option (including the rotation tensor

only) tends to overpredict the production of eddy viscosity and hence overpredicts the

eddy viscosity itself in certain circumstances.

You can select the modified form for calculating production in the Viscous Model dialog

box.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-9](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-109-320.jpg)

![Turbulence

4.3.5 Modeling the Turbulent Destruction

The destruction term is modeled as

Yν = Cw1ρfw

ν

d

2

(4.3-12)

where

fw = g

1 + C6

w3

g6 + C6

w3

1/6

(4.3-13)

g = r + Cw2 r6

− r (4.3-14)

r ≡

ν

Sκ2d2

(4.3-15)

Cw1, Cw2, and Cw3 are constants, and S is given by Equation 4.3-6. Note that the

modification described above to include the effects of mean strain on S will also affect

the value of S used to compute r.

4.3.6 Model Constants

The model constants Cb1, Cb2, σν, Cv1, Cw1, Cw2, Cw3, and κ have the following default

values [331]:

Cb1 = 0.1355, Cb2 = 0.622, σν =

2

3

, Cv1 = 7.1

Cw1 =

Cb1

κ2

+

(1 + Cb2)

σν

, Cw2 = 0.3, Cw3 = 2.0, κ = 0.4187

4.3.7 Wall Boundary Conditions

At walls, the modified turbulent kinematic viscosity, ν, is set to zero.

When the mesh is fine enough to resolve the viscosity-dominated sublayer, the wall shear

stress is obtained from the laminar stress-strain relationship:

u

uτ

=

ρuτ y

µ

(4.3-16)

4-10 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-110-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

If the mesh is too coarse to resolve the viscous sublayer, then it is assumed that the

centroid of the wall-adjacent cell falls within the logarithmic region of the boundary

layer, and the law-of-the-wall is employed:

u

uτ

=

1

κ

ln E

ρuτ y

µ

(4.3-17)

where u is the velocity parallel to the wall, uτ is the shear velocity, y is the distance from

the wall, κ is the von K´arm´an constant (0.4187), and E = 9.793.

4.3.8 Convective Heat and Mass Transfer Modeling

In ANSYS FLUENT, turbulent heat transport is modeled using the concept of the Reynolds’

analogy to turbulent momentum transfer. The “modeled” energy equation is as follows:

∂

∂t

(ρE) +

∂

∂xi

[ui(ρE + p)] =

∂

∂xj

k +

cpµt

Prt

∂T

∂xj

+ ui(τij)eff + Sh (4.3-18)

where k, in this case, is the thermal conductivity, E is the total energy, and (τij)eff is the

deviatoric stress tensor, defined as

(τij)eff = µeff

∂uj

∂xi

+

∂ui

∂xj

−

2

3

µeff

∂uk

∂xk

δij

4.4 Standard, RNG, and Realizable k- Models

This section describes the theory behind the Standard, RNG, and Realizable k- models.

Information is presented in the following sections:

• Section 4.4.1: Standard k- Model

• Section 4.4.2: RNG k- Model

• Section 4.4.3: Realizable k- Model

• Section 4.4.4: Modeling Turbulent Production in the k- Models

• Section 4.4.5: Effects of Buoyancy on Turbulence in the k- Models

• Section 4.4.6: Effects of Compressibility on Turbulence in the k- Models

• Section 4.4.7: Convective Heat and Mass Transfer Modeling in the k- Models

Release 12.0 c ANSYS, Inc. January 29, 2009 4-11](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-111-320.jpg)

![Turbulence

For details about using the models in ANSYS FLUENT, see Chapter 12: Modeling Turbulence

and Section 12.6: Setting Up the k- Model in the separate User’s Guide.

This section presents the standard, RNG, and realizable k- models. All three models

have similar forms, with transport equations for k and . The major differences in the

models are as follows:

• the method of calculating turbulent viscosity

• the turbulent Prandtl numbers governing the turbulent diffusion of k and

• the generation and destruction terms in the equation

The transport equations, the methods of calculating turbulent viscosity, and model con-

stants are presented separately for each model. The features that are essentially common

to all models follow, including turbulent generation due to shear buoyancy, accounting

for the effects of compressibility, and modeling heat and mass transfer.

4.4.1 Standard k- Model

Overview

The simplest “complete models” of turbulence are the two-equation models in which the

solution of two separate transport equations allows the turbulent velocity and length

scales to be independently determined. The standard k- model in ANSYS FLUENT falls

within this class of models and has become the workhorse of practical engineering flow

calculations in the time since it was proposed by Launder and Spalding [180]. Robust-

ness, economy, and reasonable accuracy for a wide range of turbulent flows explain its

popularity in industrial flow and heat transfer simulations. It is a semi-empirical model,

and the derivation of the model equations relies on phenomenological considerations and

empiricism.

As the strengths and weaknesses of the standard k- model have become known, im-

provements have been made to the model to improve its performance. Two of these

variants are available in ANSYS FLUENT: the RNG k- model [384] and the realizable

k- model [313].

The standard k- model [180] is a semi-empirical model based on model transport equa-

tions for the turbulence kinetic energy (k) and its dissipation rate ( ). The model trans-

port equation for k is derived from the exact equation, while the model transport equation

for was obtained using physical reasoning and bears little resemblance to its mathe-

matically exact counterpart.

In the derivation of the k- model, the assumption is that the flow is fully turbulent, and

the effects of molecular viscosity are negligible. The standard k- model is therefore valid

only for fully turbulent flows.

4-12 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-112-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

Transport Equations for the Standard k- Model

The turbulence kinetic energy, k, and its rate of dissipation, , are obtained from the

following transport equations:

∂

∂t

(ρk) +

∂

∂xi

(ρkui) =

∂

∂xj

µ +

µt

σk

∂k

∂xj

+ Gk + Gb − ρ − YM + Sk (4.4-1)

and

∂

∂t

(ρ ) +

∂

∂xi

(ρ ui) =

∂

∂xj

µ +

µt

σ

∂

∂xj

+ C1

k

(Gk + C3 Gb) − C2 ρ

2

k

+ S (4.4-2)

In these equations, Gk represents the generation of turbulence kinetic energy due to the

mean velocity gradients, calculated as described in Section 4.4.4: Modeling Turbulent

Production in the k- Models. Gb is the generation of turbulence kinetic energy due

to buoyancy, calculated as described in Section 4.4.5: Effects of Buoyancy on Turbu-

lence in the k- Models. YM represents the contribution of the fluctuating dilatation in

compressible turbulence to the overall dissipation rate, calculated as described in Sec-

tion 4.4.6: Effects of Compressibility on Turbulence in the k- Models. C1 , C2 , and C3

are constants. σk and σ are the turbulent Prandtl numbers for k and , respectively. Sk

and S are user-defined source terms.

Modeling the Turbulent Viscosity

The turbulent (or eddy) viscosity, µt, is computed by combining k and as follows:

µt = ρCµ

k2

(4.4-3)

where Cµ is a constant.

Model Constants

The model constants C1 , C2 , Cµ, σk, and σ have the following default values [180]:

C1 = 1.44, C2 = 1.92, Cµ = 0.09, σk = 1.0, σ = 1.3

These default values have been determined from experiments with air and water for funda-

mental turbulent shear flows including homogeneous shear flows and decaying isotropic

grid turbulence. They have been found to work fairly well for a wide range of wall-

bounded and free shear flows.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-13](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-113-320.jpg)

![Turbulence

Although the default values of the model constants are the standard ones most widely

accepted, you can change them (if needed) in the Viscous Model dialog box.

4.4.2 RNG k- Model

Overview

The RNG k- model was derived using a rigorous statistical technique (called renormal-

ization group theory). It is similar in form to the standard k- model, but includes the

following refinements:

• The RNG model has an additional term in its equation that significantly improves

the accuracy for rapidly strained flows.

• The effect of swirl on turbulence is included in the RNG model, enhancing accuracy

for swirling flows.

• The RNG theory provides an analytical formula for turbulent Prandtl numbers,

while the standard k- model uses user-specified, constant values.

• While the standard k- model is a high-Reynolds-number model, the RNG theory

provides an analytically-derived differential formula for effective viscosity that ac-

counts for low-Reynolds-number effects. Effective use of this feature does, however,

depend on an appropriate treatment of the near-wall region.

These features make the RNG k- model more accurate and reliable for a wider class of

flows than the standard k- model.

The RNG-based k- turbulence model is derived from the instantaneous Navier-Stokes

equations, using a mathematical technique called “renormalization group” (RNG) meth-

ods. The analytical derivation results in a model with constants different from those in

the standard k- model, and additional terms and functions in the transport equations

for k and . A more comprehensive description of RNG theory and its application to

turbulence can be found in [259].

4-14 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-114-320.jpg)

![Turbulence

4.4.3 Realizable k- Model

Overview

The realizable k- model [313] is a relatively recent development and differs from the

standard k- model in two important ways:

• The realizable k- model contains a new formulation for the turbulent viscosity.

• A new transport equation for the dissipation rate, , has been derived from an exact

equation for the transport of the mean-square vorticity fluctuation.

The term “realizable” means that the model satisfies certain mathematical constraints

on the Reynolds stresses, consistent with the physics of turbulent flows. Neither the

standard k- model nor the RNG k- model is realizable.

An immediate benefit of the realizable k- model is that it more accurately predicts

the spreading rate of both planar and round jets. It is also likely to provide superior

performance for flows involving rotation, boundary layers under strong adverse pressure

gradients, separation, and recirculation.

To understand the mathematics behind the realizable k- model, consider combining

the Boussinesq relationship (Equation 4.2-5) and the eddy viscosity definition (Equa-

tion 4.4-3) to obtain the following expression for the normal Reynolds stress in an in-

compressible strained mean flow:

u2 =

2

3

k − 2 νt

∂U

∂x

(4.4-13)

Using Equation 4.4-3 for νt ≡ µt/ρ, one obtains the result that the normal stress, u2,

which by definition is a positive quantity, becomes negative, i.e., “non-realizable”, when

the strain is large enough to satisfy

k ∂U

∂x

>

1

3Cµ

≈ 3.7 (4.4-14)

Similarly, it can also be shown that the Schwarz inequality for shear stresses (uαuβ

2

≤

u2

αu2

β; no summation over α and β) can be violated when the mean strain rate is large.

The most straightforward way to ensure the realizability (positivity of normal stresses

and Schwarz inequality for shear stresses) is to make Cµ variable by sensitizing it to

the mean flow (mean deformation) and the turbulence (k, ). The notion of variable

Cµ is suggested by many modelers including Reynolds [291], and is well substantiated

by experimental evidence. For example, Cµ is found to be around 0.09 in the inertial

sublayer of equilibrium boundary layers, and 0.05 in a strong homogeneous shear flow.

4-18 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-118-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

Both the realizable and RNG k- models have shown substantial improvements over the

standard k- model where the flow features include strong streamline curvature, vortices,

and rotation. Since the model is still relatively new, it is not clear in exactly which

instances the realizable k- model consistently outperforms the RNG model. However,

initial studies have shown that the realizable model provides the best performance of all

the k- model versions for several validations of separated flows and flows with complex

secondary flow features.

One of the weaknesses of the standard k- model or other traditional k- models lies with

the modeled equation for the dissipation rate ( ). The well-known round-jet anomaly

(named based on the finding that the spreading rate in planar jets is predicted reasonably

well, but prediction of the spreading rate for axisymmetric jets is unexpectedly poor) is

considered to be mainly due to the modeled dissipation equation.

The realizable k- model proposed by Shih et al. [313] was intended to address these

deficiencies of traditional k- models by adopting the following:

• A new eddy-viscosity formula involving a variable Cµ originally proposed by

Reynolds [291].

• A new model equation for dissipation ( ) based on the dynamic equation of the

mean-square vorticity fluctuation.

One limitation of the realizable k- model is that it produces non-physical turbulent

viscosities in situations when the computational domain contains both rotating and sta-

tionary fluid zones (e.g., multiple reference frames, rotating sliding meshes). This is due

to the fact that the realizable k- model includes the effects of mean rotation in the

definition of the turbulent viscosity (see Equations 4.4-17–4.4-19). This extra rotation

effect has been tested on single rotating reference frame systems and showed superior

behavior over the standard k- model. However, due to the nature of this modification,

its application to multiple reference frame systems should be taken with some caution.

See Section 4.4.3: Modeling the Turbulent Viscosity for information about how to include

or exclude this term from the model.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-19](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-119-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

This model has been extensively validated for a wide range of flows [167, 313], including

rotating homogeneous shear flows, free flows including jets and mixing layers, channel

and boundary layer flows, and separated flows. For all these cases, the performance of

the model has been found to be substantially better than that of the standard k- model.

Especially noteworthy is the fact that the realizable k- model resolves the round-jet

anomaly; i.e., it predicts the spreading rate for axisymmetric jets as well as that for

planar jets.

Modeling the Turbulent Viscosity

As in other k- models, the eddy viscosity is computed from

µt = ρCµ

k2

(4.4-17)

The difference between the realizable k- model and the standard and RNG k- models

is that Cµ is no longer constant. It is computed from

Cµ =

1

A0 + As

kU∗ (4.4-18)

where

U∗

≡ SijSij + ΩijΩij (4.4-19)

and

Ωij = Ωij − 2 ijkωk

Ωij = Ωij − ijkωk

where Ωij is the mean rate-of-rotation tensor viewed in a rotating reference frame with

the angular velocity ωk. The model constants A0 and As are given by

A0 = 4.04, As =

√

6 cos φ

where

φ =

1

3

cos−1

(

√

6W), W =

SijSjkSki

S3

, S = SijSij, Sij =

1

2

∂uj

∂xi

+

∂ui

∂xj

Release 12.0 c ANSYS, Inc. January 29, 2009 4-21](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-121-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

4.4.5 Effects of Buoyancy on Turbulence in the k- Models

When a non-zero gravity field and temperature gradient are present simultaneously, the

k- models in ANSYS FLUENT account for the generation of k due to buoyancy (Gb in

Equations 4.4-1, 4.4-4, and 4.4-15), and the corresponding contribution to the production

of in Equations 4.4-2, 4.4-5, and 4.4-16.

The generation of turbulence due to buoyancy is given by

Gb = βgi

µt

Prt

∂T

∂xi

(4.4-23)

where Prt is the turbulent Prandtl number for energy and gi is the component of the

gravitational vector in the ith direction. For the standard and realizable k- models,

the default value of Prt is 0.85. In the case of the RNG k- model, Prt = 1/α, where

α is given by Equation 4.4-9, but with α0 = 1/Pr = k/µcp. The coefficient of thermal

expansion, β, is defined as

β = −

1

ρ

∂ρ

∂T p

(4.4-24)

For ideal gases, Equation 4.4-23 reduces to

Gb = −gi

µt

ρPrt

∂ρ

∂xi

(4.4-25)

It can be seen from the transport equations for k (Equations 4.4-1, 4.4-4, and 4.4-15)

that turbulence kinetic energy tends to be augmented (Gb > 0) in unstable stratification.

For stable stratification, buoyancy tends to suppress the turbulence (Gb < 0). In ANSYS

FLUENT, the effects of buoyancy on the generation of k are always included when you

have both a non-zero gravity field and a non-zero temperature (or density) gradient.

While the buoyancy effects on the generation of k are relatively well understood, the

effect on is less clear. In ANSYS FLUENT, by default, the buoyancy effects on are

neglected simply by setting Gb to zero in the transport equation for (Equation 4.4-2,

4.4-5, or 4.4-16).

However, you can include the buoyancy effects on in the Viscous Model dialog box.

In this case, the value of Gb given by Equation 4.4-25 is used in the transport equation

for (Equation 4.4-2, 4.4-5, or 4.4-16).

The degree to which is affected by the buoyancy is determined by the constant C3 . In

ANSYS FLUENT, C3 is not specified, but is instead calculated according to the following

relation [127]:

Release 12.0 c ANSYS, Inc. January 29, 2009 4-23](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-123-320.jpg)

![Turbulence

C3 = tanh

v

u

(4.4-26)

where v is the component of the flow velocity parallel to the gravitational vector and

u is the component of the flow velocity perpendicular to the gravitational vector. In

this way, C3 will become 1 for buoyant shear layers for which the main flow direction is

aligned with the direction of gravity. For buoyant shear layers that are perpendicular to

the gravitational vector, C3 will become zero.

4.4.6 Effects of Compressibility on Turbulence in the k- Models

For high-Mach-number flows, compressibility affects turbulence through so-called “di-

latation dissipation”, which is normally neglected in the modeling of incompressible

flows [379]. Neglecting the dilatation dissipation fails to predict the observed decrease in

spreading rate with increasing Mach number for compressible mixing and other free shear

layers. To account for these effects in the k- models in ANSYS FLUENT, the dilatation

dissipation term, YM , is included in the k equation. This term is modeled according to

a proposal by Sarkar [300]:

YM = 2ρ M2

t (4.4-27)

where Mt is the turbulent Mach number, defined as

Mt =

k

a2

(4.4-28)

where a (≡

√

γRT) is the speed of sound.

This compressibility modification always takes effect when the compressible form of the

ideal gas law is used.

4.4.7 Convective Heat and Mass Transfer Modeling in the k- Models

In ANSYS FLUENT, turbulent heat transport is modeled using the concept of Reynolds’

analogy to turbulent momentum transfer. The “modeled” energy equation is thus given

by the following:

∂

∂t

(ρE) +

∂

∂xi

[ui(ρE + p)] =

∂

∂xj

keff

∂T

∂xj

+ ui(τij)eff + Sh (4.4-29)

where E is the total energy, keff is the effective thermal conductivity, and

(τij)eff is the deviatoric stress tensor, defined as

4-24 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-124-320.jpg)

![4.4 Standard, RNG, and Realizable k- Models

(τij)eff = µeff

∂uj

∂xi

+

∂ui

∂xj

−

2

3

µeff

∂uk

∂xk

δij

The term involving (τij)eff represents the viscous heating, and is always computed in the

density-based solvers. It is not computed by default in the pressure-based solver, but it

can be enabled in the Viscous Model dialog box.

Additional terms may appear in the energy equation, depending on the physical models

you are using. See Section 5.2.1: Heat Transfer Theory for more details.

For the standard and realizable k- models, the effective thermal conductivity is given

by

keff = k +

cpµt

Prt

where k, in this case, is the thermal conductivity. The default value of the turbulent

Prandtl number is 0.85. You can change the value of the turbulent Prandtl number in

the Viscous Model dialog box.

For the RNG k- model, the effective thermal conductivity is

keff = αcpµeff

where α is calculated from Equation 4.4-9, but with α0 = 1/Pr = k/µcp.

The fact that α varies with µmol/µeff, as in Equation 4.4-9, is an advantage of the RNG k-

model. It is consistent with experimental evidence indicating that the turbulent Prandtl

number varies with the molecular Prandtl number and turbulence [159]. Equation 4.4-9

works well across a very broad range of molecular Prandtl numbers, from liquid metals

(Pr ≈ 10−2

) to paraffin oils (Pr ≈ 103

), which allows heat transfer to be calculated in

low-Reynolds-number regions. Equation 4.4-9 smoothly predicts the variation of effective

Prandtl number from the molecular value (α = 1/Pr) in the viscosity-dominated region

to the fully turbulent value (α = 1.393) in the fully turbulent regions of the flow.

Turbulent mass transfer is treated similarly. For the standard and realizable k- models,

the default turbulent Schmidt number is 0.7. This default value can be changed in the

Viscous Model dialog box. For the RNG model, the effective turbulent diffusivity for

mass transfer is calculated in a manner that is analogous to the method used for the heat

transport. The value of α0 in Equation 4.4-9 is α0 = 1/Sc, where Sc is the molecular

Schmidt number.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-25](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-125-320.jpg)

![Turbulence

4.5 Standard and SST k-ω Models

This section describes the theory behind the Standard and SST k-ω model. Information

is presented in the following sections:

• Section 4.5.1: Standard k-ω Model

• Section 4.5.2: Shear-Stress Transport (SST) k-ω Model

• Section 4.5.3: Wall Boundary Conditions

For details about using the models in ANSYS FLUENT, see Chapter 12: Modeling Turbulence

and Section 12.7: Setting Up the k-ω Model in the separate User’s Guide.

This section presents the standard [379] and shear-stress transport (SST) [224] k-ω mod-

els. Both models have similar forms, with transport equations for k and ω. The major

ways in which the SST model [225] differs from the standard model are as follows:

• gradual change from the standard k-ω model in the inner region of the boundary

layer to a high-Reynolds-number version of the k- model in the outer part of the

boundary layer

• modified turbulent viscosity formulation to account for the transport effects of the

principal turbulent shear stress

The transport equations, methods of calculating turbulent viscosity, and methods of

calculating model constants and other terms are presented separately for each model.

4.5.1 Standard k-ω Model

Overview

The standard k-ω model in ANSYS FLUENT is based on the Wilcox k-ω model [379],

which incorporates modifications for low-Reynolds-number effects, compressibility, and

shear flow spreading. The Wilcox model predicts free shear flow spreading rates that are

in close agreement with measurements for far wakes, mixing layers, and plane, round,

and radial jets, and is thus applicable to wall-bounded flows and free shear flows. A

variation of the standard k-ω model called the SST k-ω model is also available in ANSYS

FLUENT, and is described in Section 4.5.2: Shear-Stress Transport (SST) k-ω Model.

The standard k-ω model is an empirical model based on model transport equations for

the turbulence kinetic energy (k) and the specific dissipation rate (ω), which can also be

thought of as the ratio of to k [379].

As the k-ω model has been modified over the years, production terms have been added

to both the k and ω equations, which have improved the accuracy of the model for

predicting free shear flows.

4-26 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-126-320.jpg)

![4.5 Standard and SST k-ω Models

Production of ω

The production of ω is given by

Gω = α

ω

k

Gk (4.5-13)

where Gk is given by Equation 4.5-11.

The coefficient α is given by

α =

α∞

α∗

α0 + Ret/Rω

1 + Ret/Rω

(4.5-14)

where Rω = 2.95. α∗

and Ret are given by Equations 4.5-6 and 4.5-7, respectively.

Note that, in the high-Reynolds-number form of the k-ω model, α = α∞ = 1.

Modeling the Turbulence Dissipation

Dissipation of k

The dissipation of k is given by

Yk = ρ β∗

fβ∗ k ω (4.5-15)

where

fβ∗ =

1 χk ≤ 0

1+680χ2

k

1+400χ2

k

χk > 0

(4.5-16)

where

χk ≡

1

ω3

∂k

∂xj

∂ω

∂xj

(4.5-17)

and

β∗

= β∗

i [1 + ζ∗

F(Mt)] (4.5-18)

β∗

i = β∗

∞

4/15 + (Ret/Rβ)4

1 + (Ret/Rβ)4

(4.5-19)

ζ∗

= 1.5 (4.5-20)

Release 12.0 c ANSYS, Inc. January 29, 2009 4-29](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-129-320.jpg)

![4.5 Standard and SST k-ω Models

Note that, in the high-Reynolds-number form of the k-ω model, β∗

i = β∗

∞. In the incom-

pressible form, β∗

= β∗

i .

Model Constants

α∗

∞ = 1, α∞ = 0.52, α0 =

1

9

, β∗

∞ = 0.09, βi = 0.072, Rβ = 8

Rk = 6, Rω = 2.95, ζ∗

= 1.5, Mt0 = 0.25, σk = 2.0, σω = 2.0

4.5.2 Shear-Stress Transport (SST) k-ω Model

Overview

The shear-stress transport (SST) k-ω model was developed by Menter [224] to effectively

blend the robust and accurate formulation of the k-ω model in the near-wall region with

the free-stream independence of the k- model in the far field. To achieve this, the k-

model is converted into a k-ω formulation. The SST k-ω model is similar to the standard

k-ω model, but includes the following refinements:

• The standard k-ω model and the transformed k- model are both multiplied by a

blending function and both models are added together. The blending function is

designed to be one in the near-wall region, which activates the standard k-ω model,

and zero away from the surface, which activates the transformed k- model.

• The SST model incorporates a damped cross-diffusion derivative term in the ω

equation.

• The definition of the turbulent viscosity is modified to account for the transport of

the turbulent shear stress.

• The modeling constants are different.

These features make the SST k-ω model more accurate and reliable for a wider class

of flows (e.g., adverse pressure gradient flows, airfoils, transonic shock waves) than the

standard k-ω model. Other modifications include the addition of a cross-diffusion term

in the ω equation and a blending function to ensure that the model equations behave

appropriately in both the near-wall and far-field zones.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-31](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-131-320.jpg)

![4.6 k-kl-ω Transition Model

4.6 k-kl-ω Transition Model

This section describes the theory behind the k-kl-ω Transition model. For details about

using the model in ANSYS FLUENT, see Chapter 12: Modeling Turbulence and Sec-

tion 12.8: Setting Up the Transition k-kl-ω Model in the separate User’s Guide.

4.6.1 Overview

The k-kl-ω transition model [364] is used to predict boundary layer development and

calculate transition onset. This model can be used to effectively address the transition

of the boundary layer from a laminar to a turbulent regime.

4.6.2 Transport Equations for the k-kl-ω Model

The k-kl-ω model is considered to be a three-equation eddy-viscosity type, which includes

transport equations for turbulent kinetic energy (kT ), laminar kinetic energy (kL), and

the inverse turbulent time scale (ω)

DkT

Dt

= PKT

+ R + RNAT − ωkT − DT +

∂

∂xj

ν +

αT

αk

∂kT

∂xj

(4.6-1)

DkL

Dt

= PKL

− R − RNAT − DL +

∂

∂xj

ν

∂kL

∂xj

(4.6-2)

Dω

Dt

= Cω1

ω

kT

PkT

+

CωR

fW

− 1

ω

kT

(R+RNAT )−Cω2ω2

+Cω3fωαT f2

W

√

kT

d3

+

∂

∂xj

ν +

αT

αω

∂ω

∂xj

(4.6-3)

The inclusion of the turbulent and laminar fluctuations on the mean flow and energy

equations via the eddy viscosity and total thermal diffusivity is as follows:

−uiuj = νTOT

∂Ui

∂xj

+

∂Uj

∂xi

−

2

3

kTOT δij (4.6-4)

−uiθ = αθ,TOT

∂θ

∂xi

(4.6-5)

The effective length is defined as

λeff = MIN(Cλd, λT ) (4.6-6)

where λT is the turbulent length scale and is defined by

Release 12.0 c ANSYS, Inc. January 29, 2009 4-37](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-137-320.jpg)

![4.7 Transition SST Model

αT = fνCµ,std kT,sλeff (4.6-35)

kTOT = kT + kL (4.6-36)

Model Constants

The model constants for the k-kl-ω transition model are listed below [364]

A0 = 4.04, As = 2.12, Aν = 6.75, ABP = 0.6

ANAT = 200, ATS = 200, CBP,crit = 1.2, CNC = 0.1

CNAT,crit = 1250, CINT = 0.75, CTS,crit = 1000, CR,NAT = 0.02

C11 = 3.4 × 10−6

, C12 = 1.0 × 10−10

, CR = 0.12, Cα,θ = 0.035

CSS = 1.5, Cτ,1 = 4360, Cω1 = 0.44, Cω2 = 0.92

Cω3 = 0.3, CωR = 1.5, Cλ = 2.495, Cµ,std = 0.09

Prθ = 0.85, σk = 1, σω = 1.17

4.7 Transition SST Model

This section describes the theory behind the Transition SST model. Information is

presented in the following sections:

• Section 4.7.1: Overview

• Section 4.7.2: Transport Equations for the Transition SST Model

• Section 4.7.3: Specifying Inlet Turbulence Levels

For details about using the model in ANSYS FLUENT, see Chapter 12: Modeling Turbulence

and Section 12.9: Setting Up the Transition SST Model in the separate User’s Guide.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-41](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-141-320.jpg)

![Turbulence

4.7.1 Overview

The transition SST model is based on the coupling of the SST k − ω transport equations

with two other transport equations, one for the intermittency and one for the transition

onset criteria, in terms of momentum-thickness Reynolds number. An ANSYS proprietary

empirical correlation (Langtry and Menter) has been developed to cover standard bypass

transition as well as flows in low free-stream turbulence environments.

In addition, a very powerful option has been included to allow you to enter your own

user-defined empirical correlation, which can then be used to control the transition onset

momentum thickness Reynolds number equation. To learn how to set up the transition

SST model, see Section 12.9: Setting Up the Transition SST Model (in the separate User’s

Guide).

4.7.2 Transport Equations for the Transition SST Model

The transport equation for the intermittency γ is defined as:

∂(ργ)

∂t

+

∂(ρUjγ)

∂xj

= Pγ1 − Eγ1 + Pγ2 − Eγ2 +

∂

∂xj

µ +

µt

σγ

∂γ

∂xj

(4.7-1)

The transition sources are defined as follows:

Pγ1 = 2FlengthρS[γFonset]cγ3

Eγ1 = Pγ1γ (4.7-2)

where S is the strain rate magnitude. Flength is an empirical correlation that controls the

length of the transition region. The destruction/relaminarization sources are defined as

follows:

Pγ2 = (2cγ1)ρΩγFturb

Eγ2 = cγ2Pγ2γ (4.7-3)

where Ω is the vorticity magnitude. The transition onset is controlled by the following

functions:

ReV =

ρy2

S

µ

RT =

ρk

µω

(4.7-4)

4-42 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-142-320.jpg)

![4.7 Transition SST Model

Fonset1 =

Rev

2.193Reθc

Fonset2 = min(max(Fonset1, F4

onset1), 2.0) (4.7-5)

Fonset3 = max 1 −

RT

2.5

3

, 0

Fonset = max(Fonset2 − Fonset3, 0)

Fturb = e

−

RT

4

4

(4.7-6)

Reθc is the critical Reynolds number where the intermittency first starts to increase in

the boundary layer. This occurs upstream of the transition Reynolds number Reθt and

the difference between the two must be obtained from an empirical correlation. Both the

Flength and Reθc correlations are functions of Reθt.

The constants for the intermittency equation are:

cγ1 = 0.03; cγ2 = 50; cγ3 = 0.5; σγ = 1.0

Separation Induced Transition Correction

The modification for separation-induced transition is:

γsep = min 2max

Rev

3.235Reθc

− 1, 0 Freattch, 2 Fθt

Freattch = e

−

RT

20

4

γeff = max(γ, γsep) (4.7-7)

The model constants in Equation 4.7-7 have been adjusted from those of Menter et

al. [226] in order to improve the predictions of separated flow transition. The main

difference is that the constant that controls the relation between Rev and Reθc was

changed from 2.193, its value for a Blasius boundary layer, to 3.235, the value at a

separation point where the shape factor is 3.5 [226]. The boundary condition for γ at a

wall is zero normal flux, while for an inlet, γ is equal to 1.0.

The transport equation for the transition momentum thickness Reynolds number Reθt is

∂(ρReθt)

∂t

+

∂(ρUjReθt)

∂xj

= Pθt +

∂

∂xj

σθt(µ + µt)

∂Reθt

∂xj

(4.7-8)

Release 12.0 c ANSYS, Inc. January 29, 2009 4-43](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-143-320.jpg)

![Turbulence

The source term is defined as follows:

Pθt = cθt

ρ

t

(Reθt − Reθt)(1.0 − Fθt)

t =

500µ

ρU2

(4.7-9)

Fθt = min

max

Fwakee(− y

δ )

4

, 1.0 −

γ − 1/50

1.0 − 1/50

2

, 1.0

(4.7-10)

θBL =

Reθtµ

ρU

δBL =

15

2

θBL (4.7-11)

δ =

50Ωy

U

δBL

Reω =

ρωy2

µ

Fwake = e−( Reω

1E+5 )

2

(4.7-12)

The model constants for the Reθt equation are:

cθt = 0.03 σθt = 2.0

The boundary condition for Reθt at a wall is zero flux. The boundary condition for

Reθt at an inlet should be calculated from the empirical correlation based on the inlet

turbulence intensity.

The model contains three empirical correlations. ReΘt is the transition onset as observed

in experiments. This has been modified from Menter et al. [226] in order to improve the

predictions for natural transition. It is used in Equation 4.7-9. Flength is the length of the

transition zone and is substituted in Equation 4.7-2. ReΘc is the point where the model

is activated in order to match both ReΘt and Flength, and is used in Equation 4.7-5. At

present, these empirical correlations are proprietary and are not given in this manual.

ReΘt = f(Tu, λ)

Flength = f(ReΘt)

ReΘc = f(ReΘt) (4.7-13)

4-44 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-144-320.jpg)

![4.7 Transition SST Model

The first empirical correlation is a function of the local turbulence intensity, Tu, and the

Thwaites’ pressure gradient coefficient λθ is defined as

λθ = (θ2

/v)dU/ds (4.7-14)

where dU/ds is the acceleration in the streamwise direction.

Coupling the Transition Model and SST Transport Equations

The transition model interacts with the SST turbulence model, as follows:

∂

∂t

(ρk) +

∂

∂xj

(ρujk) = Pk − Dk +

∂

∂xj

(µ + σkµt)

∂k

∂xj

(4.7-15)

Pk = γeff Pk (4.7-16)

Dk = min(max(γeff , 0.1), 1.0)Dk (4.7-17)

Ry =

ρy

√

k

µ

(4.7-18)

F3 = e− Ry

120

3

(4.7-19)

Ft = max(F1orig, F3) (4.7-20)

where Pk and Dk are the original production and destruction terms for the SST model

and F1orig is the original SST blending function. Note that the production term in the

ω-equation is not modified. The rationale behind the above model formulation is given

in detail in Menter et al. [226].

In order to capture the laminar and transitional boundary layers correctly, the mesh must

have a y+

of approximately one. If the y+

is too large (i.e. > 5), then the transition

onset location moves upstream with increasing y+

. It is recommended to use the bounded

second order upwind based discretization for the mean flow, turbulence and transition

equations.

Release 12.0 c ANSYS, Inc. January 29, 2009 4-45](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-145-320.jpg)

![4.8 The v2

-f Model

Figure 4.7.1: Decay of Turbulence Intensity (Tu) as a Function of Streamwise

Distance (x)

4.8 The v2

-f Model

The v2

-f model is similar to the standard k- model, but incorporates near-wall turbu-

lence anisotropy and non-local pressure-strain effects. A limitation of the v2

-f model is

that it cannot be used to solve Eulerian multiphase problems, whereas the k- model is

typically used in such applications. The v2

-f model is a general low-Reynolds-number

turbulence model that is valid all the way up to solid walls, and therefore does not need

to make use of wall functions. Although the model was originally developed for attached

or mildly separated boundary layers [82], it also accurately simulates flows dominated by

separation [24].

The distinguishing feature of the v2

-f model is its use of the velocity scale, v2, instead

of the turbulent kinetic energy, k, for evaluating the eddy viscosity. v2, which can be

thought of as the velocity fluctuation normal to the streamlines, has shown to provide

the right scaling in representing the damping of turbulent transport close to the wall, a

feature that k does not provide.

For more information about the theoretical background and usage of the v2

-f model,

please visit the User Services Center (www.fluentusers.com) .

Release 12.0 c ANSYS, Inc. January 29, 2009 4-47](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-147-320.jpg)

![Turbulence

4.9 Reynolds Stress Model (RSM)

This section describes the theory behind the Reynolds Stress model (RSM). Information

is presented in the following sections:

• Section 4.9.1: Overview

• Section 4.9.2: Reynolds Stress Transport Equations

• Section 4.9.3: Modeling Turbulent Diffusive Transport

• Section 4.9.4: Modeling the Pressure-Strain Term

• Section 4.9.5: Effects of Buoyancy on Turbulence

• Section 4.9.6: Modeling the Turbulence Kinetic Energy

• Section 4.9.7: Modeling the Dissipation Rate

• Section 4.9.8: Modeling the Turbulent Viscosity

• Section 4.9.9: Wall Boundary Conditions

• Section 4.9.10: Convective Heat and Mass Transfer Modeling

For details about using the model in ANSYS FLUENT, see Chapter 12: Modeling Turbulence

and Section 12.10: Setting Up the Reynolds Stress Model in the separate User’s Guide.

4.9.1 Overview

The Reynolds stress model (RSM) [108, 177, 178] is the most elaborate type of turbu-

lence model that ANSYS FLUENT provides. Abandoning the isotropic eddy-viscosity

hypothesis, the RSM closes the Reynolds-averaged Navier-Stokes equations by solving

transport equations for the Reynolds stresses, together with an equation for the dissipa-

tion rate. This means that five additional transport equations are required in 2D flows,

in comparison to seven additional transport equations solved in 3D.

Since the RSM accounts for the effects of streamline curvature, swirl, rotation, and rapid

changes in strain rate in a more rigorous manner than one-equation and two-equation

models, it has greater potential to give accurate predictions for complex flows. However,

the fidelity of RSM predictions is still limited by the closure assumptions employed to

model various terms in the exact transport equations for the Reynolds stresses. The

modeling of the pressure-strain and dissipation-rate terms is particularly challenging, and

often considered to be responsible for compromising the accuracy of RSM predictions.

4-48 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-148-320.jpg)

![Turbulence

4.9.3 Modeling Turbulent Diffusive Transport

DT,ij can be modeled by the generalized gradient-diffusion model of Daly and Harlow [67]:

DT,ij = Cs

∂

∂xk

ρ

kuku ∂uiuj

∂x

(4.9-2)

However, this equation can result in numerical instabilities, so it has been simplified in

ANSYS FLUENT to use a scalar turbulent diffusivity as follows [194]:

DT,ij =

∂

∂xk

µt

σk

∂uiuj

∂xk

(4.9-3)

The turbulent viscosity, µt, is computed using Equation 4.9-33.

Lien and Leschziner [194] derived a value of σk = 0.82 by applying the generalized

gradient-diffusion model, Equation 4.9-2, to the case of a planar homogeneous shear

flow. Note that this value of σk is different from that in the standard and realizable k-

models, in which σk = 1.0.

4.9.4 Modeling the Pressure-Strain Term

Linear Pressure-Strain Model

By default in ANSYS FLUENT, the pressure-strain term, φij, in Equation 4.9-1 is modeled

according to the proposals by Gibson and Launder [108], Fu et al. [104], and Launder [176,

177].

The classical approach to modeling φij uses the following decomposition:

φij = φij,1 + φij,2 + φij,w (4.9-4)

where φij,1 is the slow pressure-strain term, also known as the return-to-isotropy term,

φij,2 is called the rapid pressure-strain term, and φij,w is the wall-reflection term.

The slow pressure-strain term, φij,1, is modeled as

φij,1 ≡ −C1ρ

k

uiuj −

2

3

δijk (4.9-5)

with C1 = 1.8.

The rapid pressure-strain term, φij,2, is modeled as

4-50 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-150-320.jpg)

![4.9 Reynolds Stress Model (RSM)

φij,2 ≡ −C2 (Pij + Fij + 5/6Gij − Cij) −

2

3

δij(P + 5/6G − C) (4.9-6)

where C2 = 0.60, Pij, Fij, Gij, and Cij are defined as in Equation 4.9-1, P = 1

2

Pkk,

G = 1

2

Gkk, and C = 1

2

Ckk.

The wall-reflection term, φij,w, is responsible for the redistribution of normal stresses near

the wall. It tends to damp the normal stress perpendicular to the wall, while enhancing

the stresses parallel to the wall. This term is modeled as

φij,w ≡ C1

k

ukumnknmδij −

3

2

uiuknjnk −

3

2

ujuknink

C k3/2

d

+ C2 φkm,2nknmδij −

3

2

φik,2njnk −

3

2

φjk,2nink

C k3/2

d

(4.9-7)

where C1 = 0.5, C2 = 0.3, nk is the xk component of the unit normal to the wall, d is

the normal distance to the wall, and C = C3/4

µ /κ, where Cµ = 0.09 and κ is the von

K´arm´an constant (= 0.4187).

φij,w is included by default in the Reynolds stress model.

Low-Re Modifications to the Linear Pressure-Strain Model

When the RSM is applied to near-wall flows using the enhanced wall treatment described

in Section 4.12.4: Two-Layer Model for Enhanced Wall Treatment, the pressure-strain

model needs to be modified. The modification used in ANSYS FLUENT specifies the

values of C1, C2, C1, and C2 as functions of the Reynolds stress invariants and the

turbulent Reynolds number, according to the suggestion of Launder and Shima [179]:

C1 = 1 + 2.58AA2

0.25

1 − exp −(0.0067Ret)2

(4.9-8)

C2 = 0.75

√

A (4.9-9)

C1 = −

2

3

C1 + 1.67 (4.9-10)

C2 = max

2

3

C2 − 1

6

C2

, 0 (4.9-11)

with the turbulent Reynolds number defined as Ret = (ρk2

/µ ). The flatness parameter

A and tensor invariants, A2 and A3, are defined as

Release 12.0 c ANSYS, Inc. January 29, 2009 4-51](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-151-320.jpg)

![Turbulence

A ≡ 1 −

9

8

(A2 − A3) (4.9-12)

A2 ≡ aikaki (4.9-13)

A3 ≡ aikakjaji (4.9-14)

aij is the Reynolds-stress anisotropy tensor, defined as

aij = −

−ρuiuj + 2

3

ρkδij

ρk

(4.9-15)

The modifications detailed above are employed only when the enhanced wall treatment

is selected in the Viscous Model dialog box.

Quadratic Pressure-Strain Model

An optional pressure-strain model proposed by Speziale, Sarkar, and Gatski [334] is

provided in ANSYS FLUENT. This model has been demonstrated to give superior perfor-

mance in a range of basic shear flows, including plane strain, rotating plane shear, and

axisymmetric expansion/contraction. This improved accuracy should be beneficial for a

wider class of complex engineering flows, particularly those with streamline curvature.

The quadratic pressure-strain model can be selected as an option in the Viscous Model

dialog box.

This model is written as follows:

φij = − (C1ρ + C∗

1 P) bij + C2ρ bikbkj −

1

3

bmnbmnδij + C3 − C∗

3 bijbij ρkSij

+ C4ρk bikSjk + bjkSik −

2

3

bmnSmnδij + C5ρk (bikΩjk + bjkΩik) (4.9-16)

where bij is the Reynolds-stress anisotropy tensor defined as

bij = −

−ρuiuj + 2

3

ρkδij

2ρk

(4.9-17)

The mean strain rate, Sij, is defined as

Sij =

1

2

∂uj

∂xi

+

∂ui

∂xj

(4.9-18)

4-52 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-152-320.jpg)

![4.9 Reynolds Stress Model (RSM)

The mean rate-of-rotation tensor, Ωij, is defined by

Ωij =

1

2

∂ui

∂xj

−

∂uj

∂xi

(4.9-19)

The constants are

C1 = 3.4, C∗

1 = 1.8, C2 = 4.2, C3 = 0.8, C∗

3 = 1.3, C4 = 1.25, C5 = 0.4

The quadratic pressure-strain model does not require a correction to account for the

wall-reflection effect in order to obtain a satisfactory solution in the logarithmic region

of a turbulent boundary layer. It should be noted, however, that the quadratic pressure-

strain model is not available when the enhanced wall treatment is selected in the Viscous

Model dialog box.

Low-Re Stress-Omega Model

The low-Re stress-omega model is a stress-transport model that is based on the omega

equations and LRR model [379]. This model is ideal for modeling flows over curved sur-

faces and swirling flows. The low-Re stress-omega model can be selected in the Viscous

Model dialog box and requires no treatments of wall reflections. The closure coeffi-

cients are identical to the k-ω model (Section 4.5.1: Model Constants), however, there

are additional closure coefficients, C1 and C2, noted below.

The low-Re stress-omega model resembles the k-ω model due to its excellent predictions

for a wide range of turbulent flows. Furthermore, low Reynolds number modifications

and surface boundary conditions for rough surfaces are similar to the k-ω model.

Equation 4.9-4 can be re-written for the low-Re stress-omega model such that wall re-

flections are excluded:

φij = φij,1 + φij,2 (4.9-20)

Therefore,

φij = −C1ρβ∗

RSM ω ui uj − 2/3δijk − ˆα0 [Pij − 1/3Pkkδij]

− ˆβ0 [Dij − 1/3Pkkδij] − k ˆγ0 [Sij − 1/3Skkδij] (4.9-21)

where Dij is defined as

Release 12.0 c ANSYS, Inc. January 29, 2009 4-53](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-153-320.jpg)

![Turbulence

Dij = −ρ ui um

∂um

∂xj

+ uj um

∂um

∂xi

(4.9-22)

The mean strain rate Sij is defined in Equation 4.9-18 and β∗

RSM is defined by

β∗

RSM = β∗

fβ∗ (4.9-23)

where β∗

and f∗

β are defined in the same way as for the standard k − ω, using Equa-

tions 4.5-16 and 4.5-22, respectively. The only difference here is that the equation for f∗

β

uses a value of 640 instead of 680, as in Equation 4.5-16.

The constants are

ˆα0 =

8 + C2

11

, ˆβ0 =

8C2 − 2

11

, ˆγ0 =

60C2 − 4

55

C1 = 1.8, C2 = 0.52

The above formulation does not require viscous damping functions to resolve the near-

wall sublayer. However, inclusion of the viscous damping function [379] could improve

model predictions for certain flows. This results in the following changes:

ˆα =

1 + ˆα0ReT /Rk

1 + ReT /Rk

ˆβ = ˆβ0

ReT /Rk

1 + ReT /Rk

ˆγ = ˆγ0

0.007 + ReT /Rk

1 + ReT /Rk

C1 = 1.8

5/3 + ReT /Rk

1 + ReT /Rk

where ˆα, ˆβ, and ˆγ would replace ˆα0, ˆβ0, and ˆγ0 in Equation 4.9-21. The constants are

Rβ = 12, Rk = 12, Rω = 6.20

Inclusion of the low-Re viscous damping is controlled by enabling Low-Re Corrections

under k-omega Options in the Viscous Model dialog box.

4-54 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-154-320.jpg)

![Turbulence

Although Equation 4.9-28 is solved globally throughout the flow domain, the values of k

obtained are used only for boundary conditions. In every other case, k is obtained from

Equation 4.9-27. This is a minor point, however, since the values of k obtained with

either method should be very similar.

4.9.7 Modeling the Dissipation Rate

The dissipation tensor, ij, is modeled as

ij =

2

3

δij(ρ + YM ) (4.9-29)

where YM = 2ρ M2

t is an additional “dilatation dissipation” term according to the model

by Sarkar [300]. The turbulent Mach number in this term is defined as

Mt =

k

a2

(4.9-30)

where a (≡

√

γRT) is the speed of sound. This compressibility modification always takes

effect when the compressible form of the ideal gas law is used.

The scalar dissipation rate, , is computed with a model transport equation similar to

that used in the standard k- model:

∂

∂t

(ρ ) +

∂

∂xi

(ρ ui) =

∂

∂xj

µ +

µt

σ

∂

∂xj

C 1

1

2

[Pii + C 3Gii]

k

− C 2ρ

2

k

+ S (4.9-31)

where σ = 1.0, C 1 = 1.44, C 2 = 1.92, C 3 is evaluated as a function of the local flow

direction relative to the gravitational vector, as described in Section 4.4.5: Effects of

Buoyancy on Turbulence in the k- Models, and S is a user-defined source term.

In the case when the Reynolds Stress model is coupled with the omega equation, the

dissipation tensor ij is modeled as

ij = 2/3δijρβ∗

RSM kω (4.9-32)

Where β∗

RSM is defined in Section 4.9.4: Modeling the Pressure-Strain Term and the

specific dissipation rate ω is computed in the same way as for the standard k − ω model,

using Equation 4.5-2.

4-56 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-156-320.jpg)

![Turbulence

where uτ is the friction velocity defined by uτ ≡ τw/ρ, where τw is the wall-shear stress.

When this option is chosen, the k transport equation is not solved.

When using enhanced wall treatments as the near-wall treatment, ANSYS FLUENT ap-

plies zero flux wall boundary conditions to the Reynolds stress equations.

4.9.10 Convective Heat and Mass Transfer Modeling

With the Reynolds stress model in ANSYS FLUENT, turbulent heat transport is modeled

using the concept of Reynolds’ analogy to turbulent momentum transfer. The “modeled”

energy equation is thus given by the following:

∂

∂t

(ρE) +

∂

∂xi

[ui(ρE + p)] =

∂

∂xj

k +

cpµt

Prt

∂T

∂xj

+ ui(τij)eff + Sh (4.9-36)

where E is the total energy and (τij)eff is the deviatoric stress tensor, defined as

(τij)eff = µeff

∂uj

∂xi

+

∂ui

∂xj

−

2

3

µeff

∂uk

∂xk

δij

The term involving (τij)eff represents the viscous heating, and is always computed in the

density-based solvers. It is not computed by default in the pressure-based solver, but it

can be enabled in the Viscous Model dialog box. The default value of the turbulent

Prandtl number is 0.85. You can change the value of Prt in the Viscous Model dialog

box.

Turbulent mass transfer is treated similarly, with a default turbulent Schmidt number of

0.7. This default value can be changed in the Viscous Model dialog box.

4.10 Detached Eddy Simulation (DES)

This section describes the theory behind the Detached Eddy Simulation (DES) model.

Information is presented in the following sections:

• Section 4.10.1: Spalart-Allmaras Based DES Model

• Section 4.10.2: Realizable k- Based DES Model

• Section 4.10.3: SST k-ω Based DES Model

For details about using the model in ANSYS FLUENT, see Chapter 12: Modeling Turbulence

and Section 12.11: Setting Up the Detached Eddy Simulation Model in the separate User’s

Guide.

4-58 Release 12.0 c ANSYS, Inc. January 29, 2009](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-158-320.jpg)

![4.10 Detached Eddy Simulation (DES)

Overview

ANSYS FLUENT offers three different models for the detached eddy simulation: the

Spalart-Allmaras model, the realizable k- model, and the SST k-ω model.

In the DES approach, the unsteady RANS models are employed in the boundary layer,

while the LES treatment is applied to the separated regions. The LES region is normally

associated with the core turbulent region where large unsteady turbulence scales play a

dominant role. In this region, the DES models recover LES-like subgrid models. In the

near-wall region, the respective RANS models are recovered.

DES models have been specifically designed to address high Reynolds number wall

bounded flows, where the cost of a near-wall resolving Large Eddy Simulation would

be prohibitive. The difference with the LES model is that it relies only on the required

resolution in the boundary layers. The application of DES, however, may still require

significant CPU resources and therefore, as a general guideline, it is recommended that

the conventional turbulence models employing the Reynolds-averaged approach be used

for practical calculations.

The DES models, often referred to as the hybrid LES/RANS models combine RANS

modeling with LES for applications such as high-Re external aerodynamics simulations.

In ANSYS FLUENT, the DES model is based on the one-equation Spalart-Allmaras model,

the realizable k- model, and the SST k-ω model. The computational costs, when using

the DES models, is less than LES computational costs, but greater than RANS.

4.10.1 Spalart-Allmaras Based DES Model

The standard Spalart-Allmaras model uses the distance to the closest wall as the defini-

tion for the length scale d, which plays a major role in determining the level of production

and destruction of turbulent viscosity (Equations 4.3-6, 4.3-12, and 4.3-15). The DES

model, as proposed by Shur et al. [314] replaces d everywhere with a new length scale d,

defined as

d = min(d, Cdes∆) (4.10-1)

where the grid spacing, ∆, is based on the largest grid space in the x, y, or z directions

forming the computational cell. The empirical constant Cdes has a value of 0.65.

For a typical RANS grid with a high aspect ratio in the boundary layer, and where the

wall-parallel grid spacing usually exceeds δ, where δ is the size of the boundary layer,

Equation 4.10-1 will ensure that the DES model is in the RANS mode for the entire

boundary layer. However, in case of an ambiguous grid definition, where ∆ << δ, the

DES limiter can activate the LES mode inside the boundary layer, where the grid is not

fine enough to sustain resolved turbulence. Therefore, a new formulation [332] of DES

Release 12.0 c ANSYS, Inc. January 29, 2009 4-59](https://image.slidesharecdn.com/flth-130501182911-phpapp02/85/Flth-159-320.jpg)

![4.11 Large Eddy Simulation (LES) Model

4.10.3 SST k-ω Based DES Model

The dissipation term of the turbulent kinetic energy (see Section 4.5.1: Modeling the Tur-

bulence Dissipation) is modified for the DES turbulence model as described in Menter’s

work [225] such that

Yk = ρβ∗

kωFDES (4.10-9)

where FDES is expressed as

FDES = max

Lt

Cdes∆

, 1 (4.10-10)

where Cdes is a calibration constant used in the DES model and has a value of 0.61, ∆ is

the maximum local grid spacing (∆x, ∆y, ∆z).

The turbulent length scale is the parameter that defines this RANS model:

Lt =

√

k

β∗ω

(4.10-11)

The DES-SST model also offers the option to “protect” the boundary layer from the

limiter (delayed option). This is achieved with the help of the zonal formulation of the

SST model. FDES is modified according to

FDES = max

Lt

Cdes∆

(1 − FSST ), 1 (4.10-12)