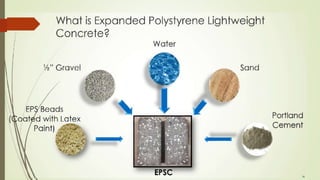

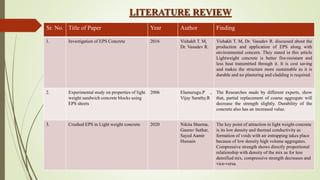

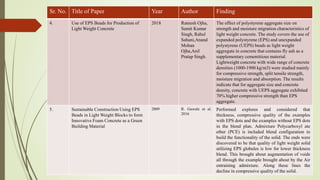

This document provides details about a study investigating the properties of concrete with expanded polystyrene (EPS) used as a partial or full replacement for natural sand. The study aims to gauge the strength, workability, and durability of concrete mixtures with 1%, 1.5%, 2%, 4%, and 6% replacements of fine aggregate with EPS. It outlines the objectives, methodology, literature review, and schedule. Tests will include slump cone tests for workability, compressive strength tests, and water absorption tests. Results will be presented in graphs and charts to compare materials.