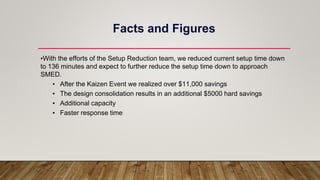

Initial observations of fitting setup data found approximately 25 setups annually on fitting machines, with an average setup time of over 300 minutes and a cost of $1.59 per minute. Through efforts to standardize fittings and reduce setup times, the team reduced the average setup time to 136 minutes, realizing over $11,000 in savings from the reduced time. A design consolidation provided an additional $5,000 in hard savings, while freeing up capacity and enabling faster response times. Inventory was also reduced by 38% through introducing IPK to reduce work-in-process levels.