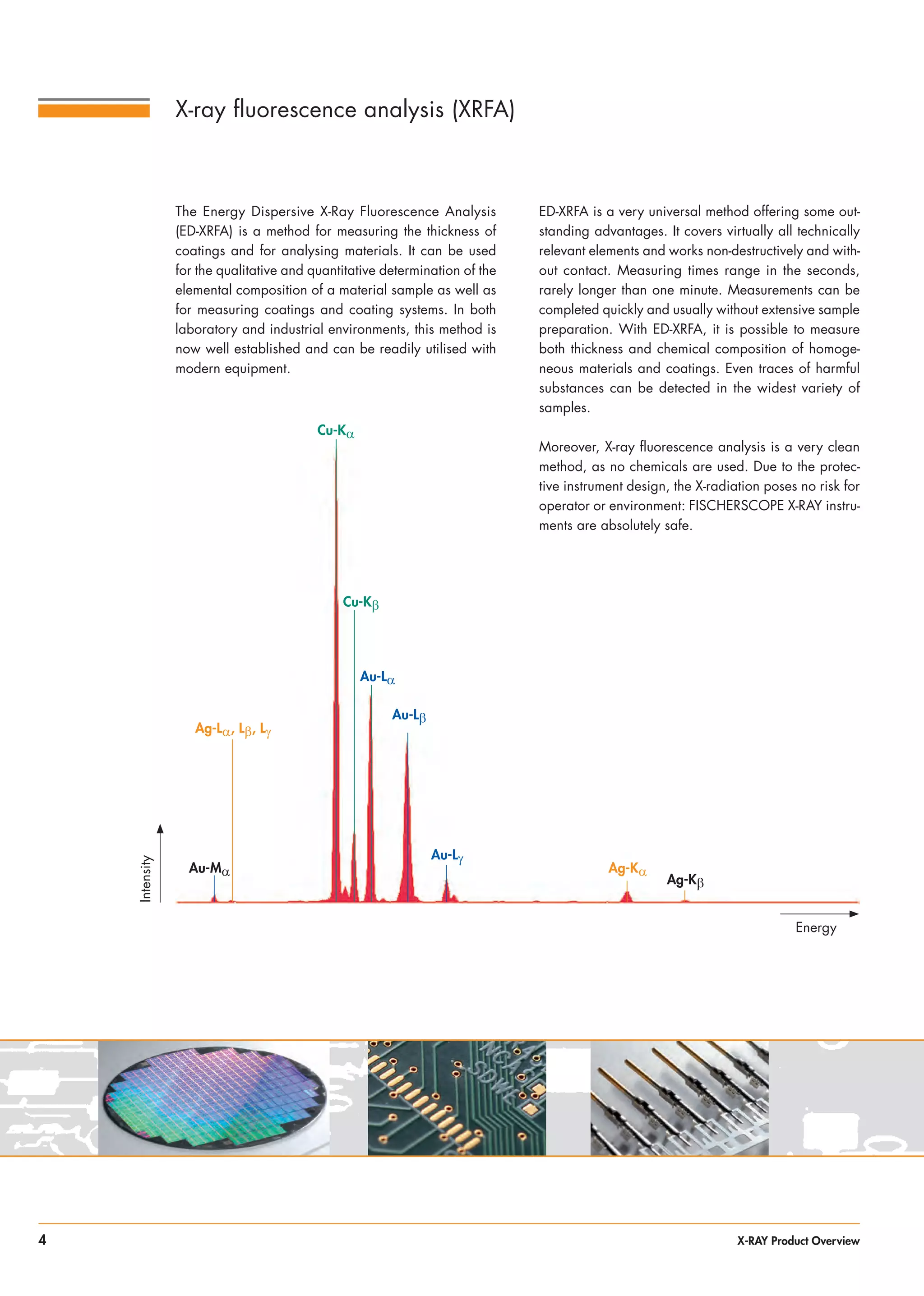

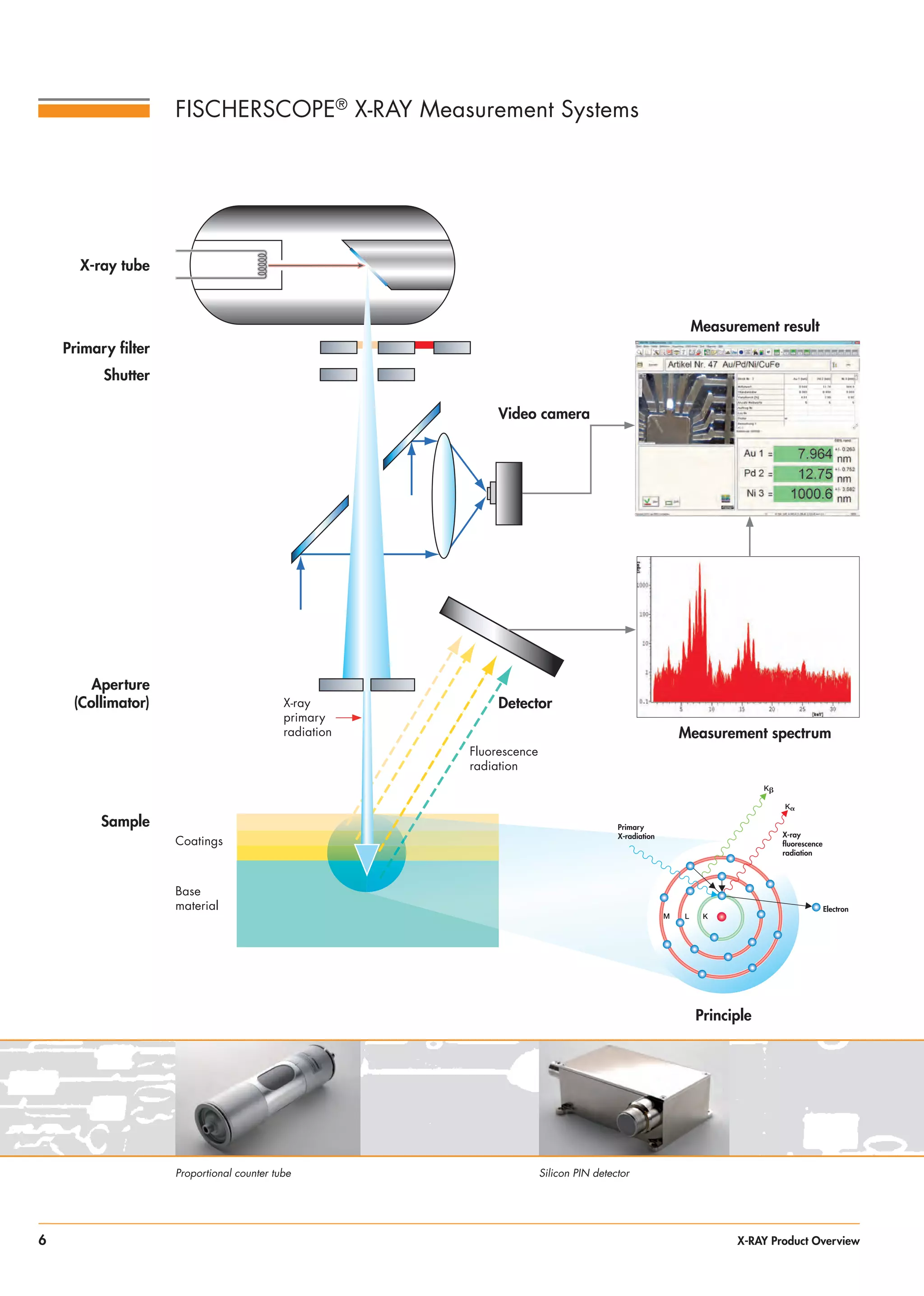

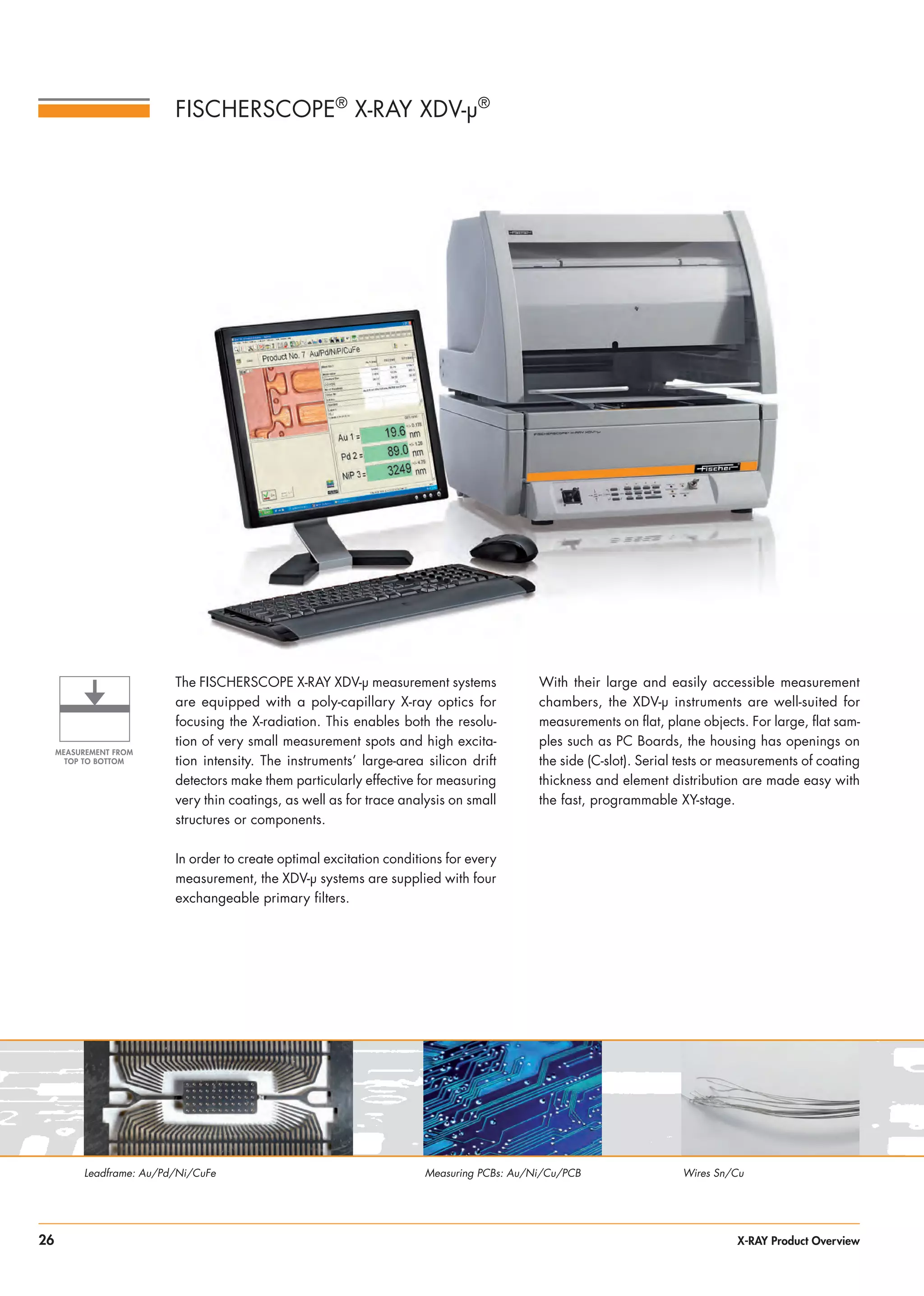

Fischer has been a leader in x-ray fluorescence measuring technology since 1953, developing instruments for coating thickness measurement and material analysis. Its fischerscope x-ray systems are used globally for precise and reliable measurements across various industries, thanks to innovations like the transparent aperture and advanced software. The energy dispersive x-ray fluorescence analysis method provides non-destructive, fast measurements while ensuring safety and compliance with regulations.