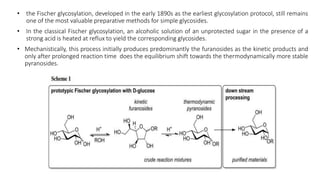

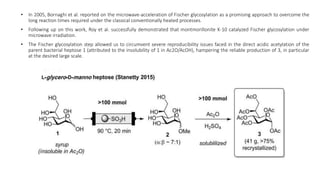

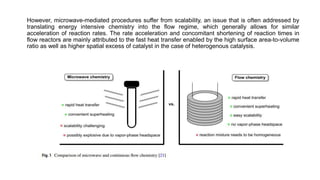

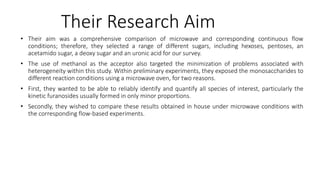

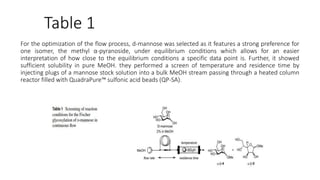

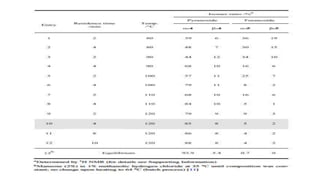

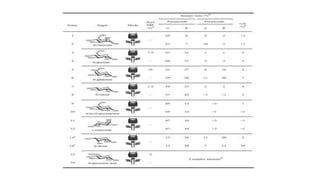

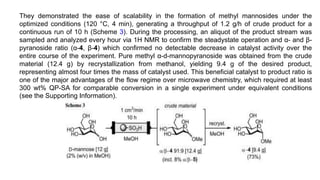

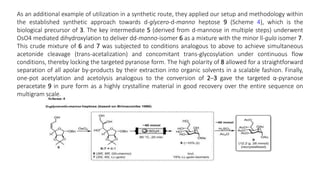

This document describes research into translating the Fischer glycosylation reaction from batch microwave heating to continuous flow processing. The researchers optimized conditions for a continuous flow reactor packed with a heterogeneous acid catalyst to efficiently produce methyl glycosides from various monosaccharides. They demonstrated high consistency between product ratios obtained via continuous flow and microwave batch reactions. The scalability of the continuous flow process was shown through producing gram quantities of methyl mannoside over 10 hours, as well as applying the flow conditions in the multi-step synthesis of d-glycero-d-manno heptose on a multigram scale.