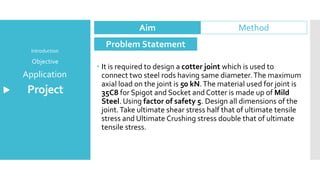

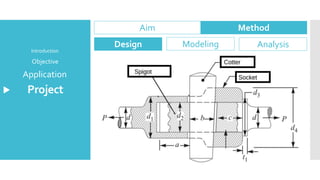

1) The document describes a finite element analysis project to design and simulate a cotter joint connecting two steel rods.

2) The objectives of the project are to learn modeling, design optimization, finite element analysis, and CAD/CAE software skills.

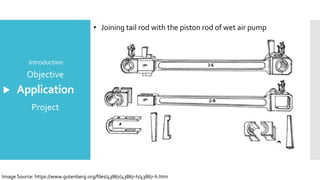

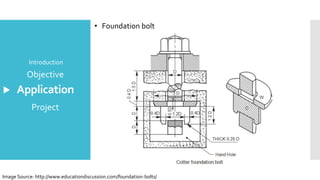

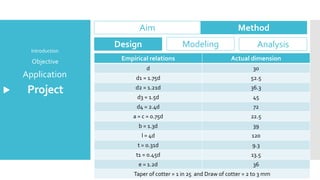

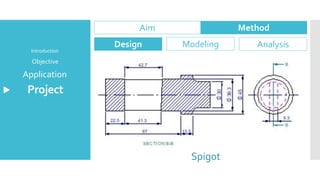

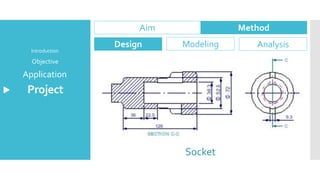

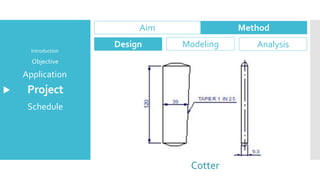

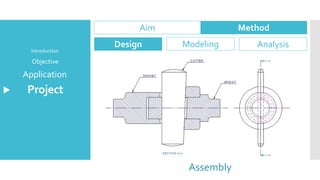

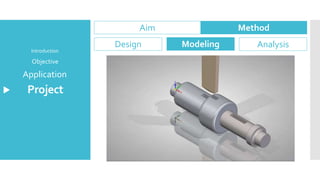

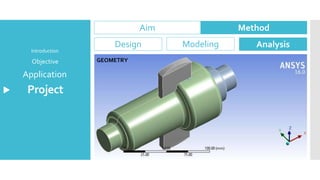

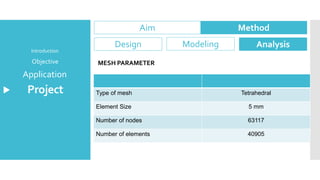

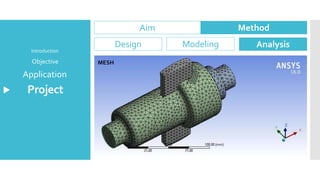

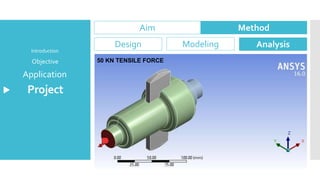

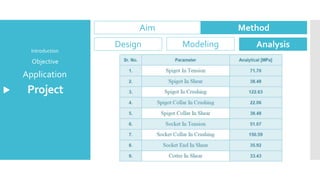

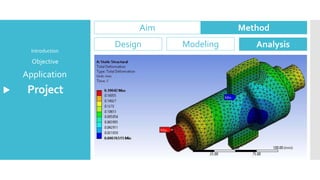

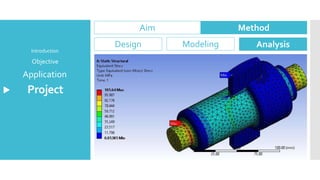

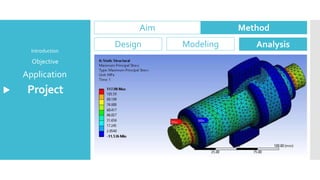

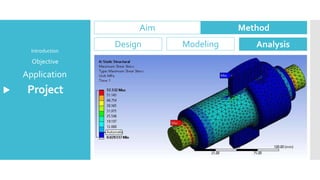

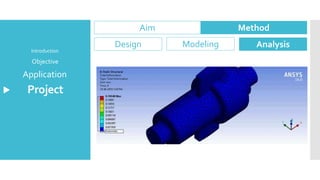

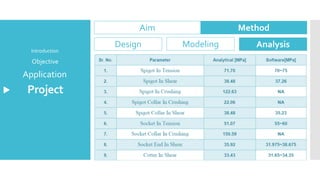

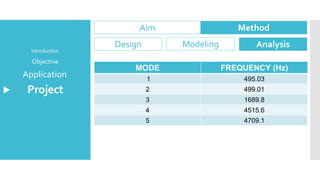

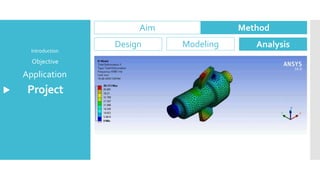

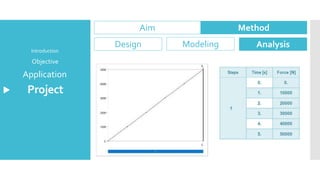

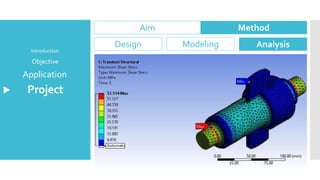

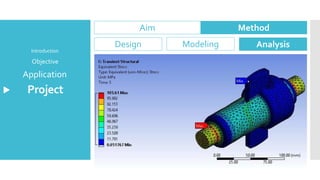

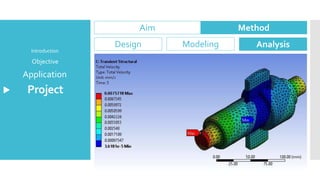

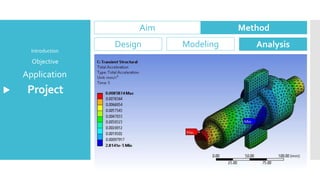

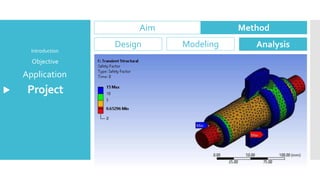

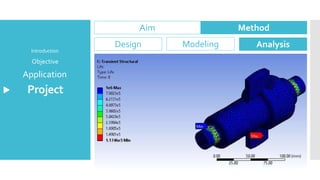

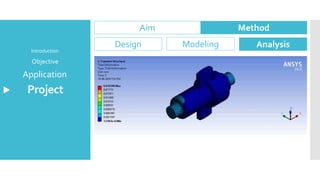

3) A cotter joint connecting two 30mm diameter rods and experiencing a maximum axial load of 50kN is designed, modeled, meshed, and simulated under static, modal, and transient loads.

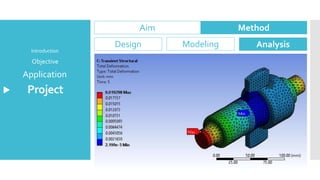

4) The results of the simulations show the induced stresses are less than permissible stresses, indicating the joint will perform safely under actual operating conditions if manufactured as designed.