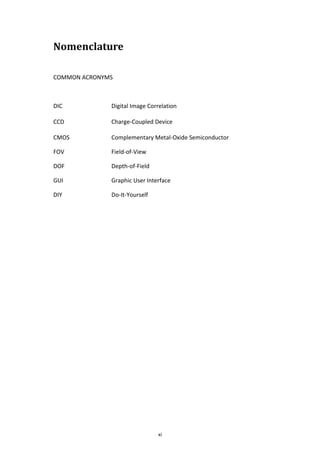

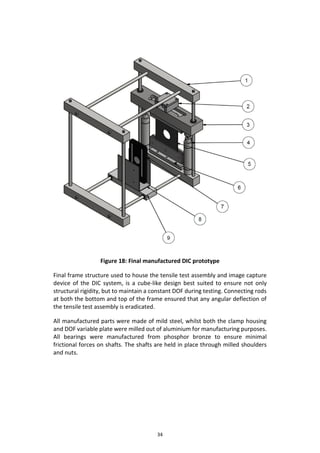

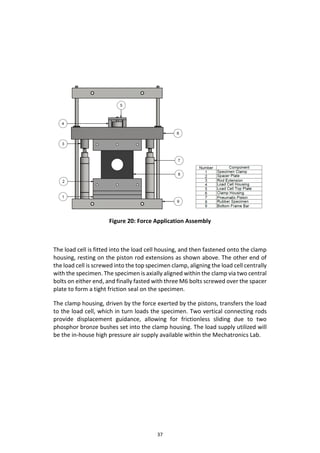

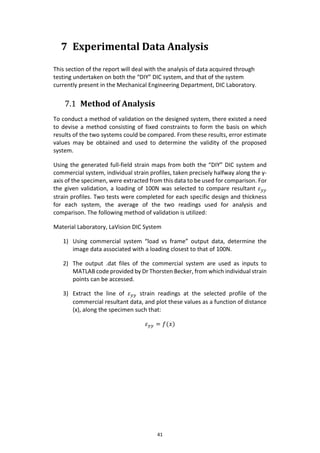

The document presents the design and implementation of a "DIY" (do-it-yourself) digital image correlation (DIC) system. The objectives are to design a lower-cost and more portable alternative to commercial DIC systems using cheaper materials. A literature review of DIC components and techniques was conducted. Concepts were generated and evaluated before selecting a final design. The prototype was built using a smartphone camera, low-cost tensile test mechanism, and open-source software. Experimental testing showed the DIY system could produce strain maps within an acceptable error range compared to commercial systems, validating the design for classroom demonstrations and preliminary sample testing.

![5

DIC has proven to be a more cost-effective and simpler method of strain

measurement than other techniques such as speckle interferometery, and has

shown to be a more accurate than manual methods of measurement such as

extensometers. DIC is most suited to applications such as crack propagation

measurement and situations in which a full field deformation map is required.

(Solutions, 2015)

Interest in DIC has grown over the past few years due to a number of reasons, the

main cause being the rapid improvement of charge-coupled device (CCD) and

complementary metal-oxide-semiconductor (CMOS) sensor-based cameras whilst

cost of these devices has decreased substantially. The dynamic range of these

cameras has allowed for a multitude of possible applications. Dynamic range is

measured in bit depth, which is defined as the number of bits of information in a

single sample and is directly related to resolution of each sample (DALSA, 2015).

Modern cameras generally have a bit size varying from 8 to 14-bit and it is this

improved resolution that has driven the movement towards greater DIC use.

A complete DIC system consists of 3 main components, namely a loading

mechanism, image capture device and some form of image acquisition and

processing station. Common DIC systems make use of a tensile testing machine as

the loading mechanism, but compression machines can be used if needed. Image

acquisition and processing is achieved through the implementation of high-speed

correlation software. A large number of software packages are available, but all

software tends to utilize similar correlation algorithms.

The correlation algorithm is utilized by having the software initially divide the

chosen field-of-view (FOV) into a number of smaller subsections, called subsets

(Yoneyama & Murasawa, 2013). These subsets are essentially a group of random

coordinate points. As the specimen undergoes loading, these various subsets

undergo a spatial transformation. DIC commonly makes use of a function known

as the correlation coefficient, and is shown in equation 2.1.

𝑟𝑖𝑗 (𝑢, 𝑣,

𝜕𝑢

𝜕𝑥

,

𝜕𝑢

𝜕𝑦

,

𝜕𝑣

𝜕𝑥

,

𝜕𝑣

𝜕𝑦

) = 1 −

∑𝑖∑ 𝑗[𝐹(𝑥 𝑖,𝑦 𝑗)−𝐹̅][𝐺(𝑥 𝑖

∗

,𝑦 𝑗

∗

)−𝐺̅]

√∑𝑖∑ 𝑗[𝐹(𝑥 𝑖,𝑦 𝑗)−𝐹̅]

2

∑𝑖∑ 𝑗[𝐺(𝑥 𝑖

∗,𝑦 𝑗

∗)−𝐺̅]

2

(2.1)

In this equation, F(xi,yj) is the grey scale value at a point (xi,yj) in the initial

reference image and G(xi*,yj*) is the grey scale value at a point (xi*,yj*) in the

following, deformed image. 𝐹̅ and 𝐺̅ are the mean values of the gray scale values

of matrices F and G, respectively (H.A. Bruck, 1989). This equation is relatively

complicated and for 2D DIC the relation between (xi,yj) and (xi*,yj*) can be

approximated as a linear, first order transformation equation as shown below in

equation 2.2 and 2.3:](https://image.slidesharecdn.com/42007b31-8bd2-4dcb-9861-cbefe989c049-160901171126/85/Final-Thesis-Report-18-320.jpg)

![13

𝒙 𝒄𝒖𝒓,𝒊 = 𝒙 𝒓𝒆𝒇,𝒊 + 𝒖 𝒓𝒄 +

𝝏𝒖

𝝏𝒙 𝒓𝒄

(𝒙 𝒓𝒆𝒇,𝒊 − 𝒙 𝒓𝒆𝒇,𝒄) +

𝝏𝒖

𝝏𝒚 𝒓𝒄

(𝒚 𝒓𝒆𝒇,𝒊 − 𝒚 𝒓𝒆𝒇,𝒄) (4)

𝐲𝒄𝒖𝒓,𝒊 = 𝐲𝒓𝒆𝒇,𝒊 + 𝐯𝒓𝒄 +

𝝏𝒗

𝝏𝒙 𝒓𝒄

(𝒙 𝒓𝒆𝒇,𝒊 − 𝒙 𝒓𝒆𝒇,𝒄) +

𝝏𝒗

𝝏𝒚 𝒓𝒄

(𝒚 𝒓𝒆𝒇,𝒊 − 𝒚 𝒓𝒆𝒇,𝒄) (5)

𝑥 𝑟𝑒𝑓,𝑖 and 𝑦 𝑟𝑒𝑓,𝑖indicate the x and y coordinates of an initial reference subset point,

𝑥 𝑟𝑒𝑓,𝑐 and 𝑦 𝑟𝑒𝑓,𝑐 the x and y coordinates of the center of the initial reference

subset and 𝑥 𝑐𝑢𝑟,𝑖 and 𝑦𝑐𝑢𝑟,𝑖 the x and y coordinates of the final current subset

point. (i,j) coordinates are used to indicate a relevant location of subset points

with respect to the center of the subset. The subscript “rc” indicates the

transformation from the reference to the current coordinate system (Blaber,

2015).

A deformation vector, p, is defined below as column vector of all transformation

functions:

𝒑 = { 𝒖 𝒗

𝝏𝒖

𝝏𝒙

𝝏𝒖

𝝏𝒚

𝝏𝒗

𝝏𝒙

𝝏𝒗

𝝏𝒚

} 𝑻

(6)

Equation 4 and 5 can be written into matrix form, where ξ is an augmented vector

containing the x and y coordinates of subset points, Δx and Δy the distances

between a subset point and the center of the subset, and “w” defined as function

called a warp. The matrix form is shown below:

𝝃 𝒓𝒆𝒇,𝒄 + 𝒘(𝜟𝝃 𝒓𝒆𝒇, 𝒑 𝒓𝒄) = {

𝒙 𝒓𝒆𝒇,𝒄

𝑻

𝒚 𝒓𝒆𝒇,𝒄

𝑻

𝟏

} +

[

𝟏 +

𝒅𝒖

𝒅𝒙 𝒓𝒄

𝒅𝒖

𝒅𝒚 𝒓𝒄

𝒖 𝒓𝒄

𝒅𝒗

𝒅𝒙 𝒓𝒄

𝟏 +

𝒅𝒗

𝒅𝒚 𝒓𝒄

𝒗 𝒓𝒄

𝟎 𝟎 𝟏 ]

∗ {

𝜟𝒙 𝒓𝒆𝒇

𝑻

𝜟𝒚 𝒓𝒆𝒇

𝑻

𝟏

} (7)

For computational purposes, the reference subset is allowed to deform within the

reference configuration as shown below:

𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊 = 𝒙 𝒓𝒆𝒇,𝒊 + 𝒖 𝒓𝒓 +

𝝏𝒖

𝝏𝒙 𝒓𝒓

(𝒙 𝒓𝒆𝒇,𝒊 − 𝒙 𝒓𝒆𝒇,𝒄)

+

𝝏𝒖

𝝏𝒚 𝒓𝒓

(𝒚 𝒓𝒆𝒇,𝒊 − 𝒚 𝒓𝒆𝒇,𝒄) (8)

𝒚 𝒏𝒆𝒘𝒓𝒆𝒇,𝒋 = 𝒚 𝒓𝒆𝒇,𝒊 + 𝒗 𝒓𝒓 +

𝝏𝒗

𝝏𝒙 𝒓𝒄

(𝒙 𝒓𝒆𝒇,𝒊 − 𝒙 𝒓𝒆𝒇,𝒄) +

𝝏𝒗

𝝏𝒚 𝒓𝒄

(𝒚 𝒓𝒆𝒇,𝒊 − 𝒚 𝒓𝒆𝒇,𝒄) (9)](https://image.slidesharecdn.com/42007b31-8bd2-4dcb-9861-cbefe989c049-160901171126/85/Final-Thesis-Report-26-320.jpg)

![14

𝑥 𝑛𝑒𝑤𝑟𝑒𝑓,𝑖 and 𝑦 𝑛𝑒𝑤𝑟𝑒𝑓,𝑗 are the x and y coordinates of a final reference subset. The

use of the “rr” subscript is to indicate transformation from the reference

coordinate system to the reference coordinate system. For the computational

purposes, is desired to find the optimal prc, when prr = 0, such that the coordinates

at 𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊 and 𝑦 𝑛𝑒𝑤𝑟𝑒𝑓,𝑗 are approximately equal to the coordinates at

𝑥 𝑐𝑢𝑟,𝑖 andy 𝑐𝑢𝑟,𝑖 .

The program is similar to conventional systems in using correlation criteria, a

means to establish a metric for similarity between the final reference subset and

the final current subset. The program does so by comparing grayscale values at

the final reference subset points with grayscale values at the final current subset

points. The two equations implemented within the program are shown below:

𝑪 𝒄𝒄 =

𝜮(𝒊,𝒋)(𝒇(𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊 ,𝒚 𝒏𝒆𝒘𝒓𝒆𝒇,𝒋)−𝒇 𝒎)(𝒈(𝒙 𝒄𝒖𝒓,𝒊,𝒚 𝒄𝒖𝒓,𝒋)−𝒈 𝒎)

√ 𝜮(𝒊,𝒋)[𝒇(𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊,𝒚 𝒏𝒆𝒘𝒓𝒆𝒇,𝒋)−𝒇 𝒎]

𝟐

𝜮(𝒊,𝒋)[𝒈(𝒙 𝒄𝒖𝒓,𝒊,𝒚 𝒄𝒖𝒓,𝒋)−𝒈 𝒎] 𝟐

(10)

𝑪 𝑳𝑺 = 𝜮(𝒊,𝒋) [

𝒇(𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊 ,𝒚 𝒏𝒆𝒘𝒓𝒆𝒇,𝒋)−𝒇 𝒎

√ 𝜮(𝒊,𝒋)[𝒇(𝒙 𝒏𝒆𝒘𝒓𝒆𝒇,𝒊,𝒚 𝒏𝒆𝒘𝒓𝒆𝒇,𝒋)−𝒇 𝒎]

𝟐

−

𝒈(𝒙 𝒄𝒖𝒓,𝒊,𝒚 𝒄𝒖𝒓,𝒋)−𝒈 𝒎

√𝜮(𝒊,𝒋)[𝒈(𝒙 𝒄𝒖𝒓,𝒊,𝒚 𝒄𝒖𝒓,𝒋)−𝒈 𝒎] 𝟐

] 𝟐

(11)

The formulas f and g indicate the reference and current image functions,

respectively, and return a grayscale value corresponding to the specified (x,y)

point. The grayscale values of the final reference and current subset are defined

as fm and gm respectively, and are shown below in the following equations:

𝑓𝑚 =

𝛴(𝑖,𝑗) 𝑓(𝑥 𝑛𝑒𝑤𝑟𝑒𝑓,𝑖, 𝑦 𝑛𝑒𝑤𝑟𝑒𝑓,𝑗)

𝑛(𝑆)

𝑔 𝑚 =

𝛴(𝑖,𝑗) 𝑔(𝑥 𝑐𝑢𝑟,𝑖, 𝑦𝑐𝑢𝑟,𝑗

𝑛(𝑆)

Where n(S) is the number of elements in S, the set which contains all the subset

points.](https://image.slidesharecdn.com/42007b31-8bd2-4dcb-9861-cbefe989c049-160901171126/85/Final-Thesis-Report-27-320.jpg)

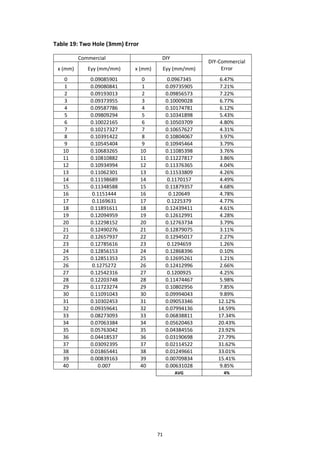

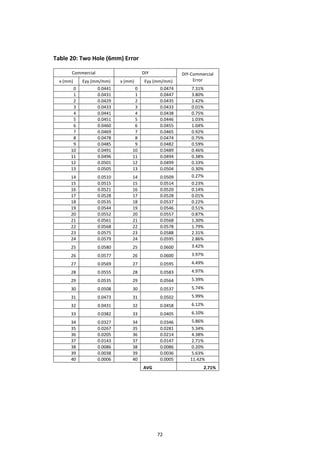

![50

10 Bibliography

Albert, T., 2014. Thwing-Albert Tensile Tester Grips & Fixtures. [Online]

Available at: http://www.thwingalbert.com/tensile-tester-grips-fixtures.html

Blaber, J., 2015. Ncorr Open Source 2D Digital Image Correlation MATLAB

Program. [Online]

Available at: www.ncorr.com

Budynas, R. G. & Nisbett, J. K., 2011. Shigley's Mechanical Engineering Design.

Singapore: The McGraw-Hill Companies.

Corporation, M. S., 2015. Load Frames. [Online]

Available at: http://www.mts.com/mtscriterion/products/test_systems/

[Accessed 14 June 2015].

DALSA, T., 2015. CCD vs. CMOS. [Online]

Available at: https://www.teledynedalsa.com/corp/

[Accessed 10 March 2015].

Gharagozlou, Y., 2014. Tensile Testing - What is Tensile Testing?. [Online]

Available at: http://www.instron.com/en/our-company/library/test-

types/tensile-test

[Accessed 22 May 2015].

Gharagozlou, Y., 2015. Industrial Series DX/HDX Models. [Online]

Available at: http://www.instron.com/en/products/testing-systems/universal-

testing-systems/static-hydraulic/dx

[Accessed 14 May 2015].

H.A. Bruck, S. M. M. S. a. W. P. I., 1989. Digital Image Correlation Using Newton-

Raphson Method of Partial Differential Correction. Experimental Mechanics,

II(12), pp. 261-267.

M.R. Maschmann, G. E. S. P. D. M. B. M. A. H. J. B., 2012. VISUALIZING STRAIN

EVOLUTION AND COORDINATED BUCKLING IN CNT ARRAYS BY IN SITU DIGITAL

IMAGE CORRELATION. [Online]

Available at: http://mechanosynthesis.mit.edu/?p=2825

[Accessed 22 April 2015].

Solutions, C., 2015. Principle of Digital Image Correlation. [Online]

Available at: http://www.correlatedsolutions.com/digital-image-correlation/](https://image.slidesharecdn.com/42007b31-8bd2-4dcb-9861-cbefe989c049-160901171126/85/Final-Thesis-Report-63-320.jpg)

![51

[Accessed 12 February 2015].

Sutton, M. A., Orteu, J. J. & Schreier, H. W., 2009. mage Correlation for Shape,

Motion and Deformation Measurements. 1st ed. New York: Springer.

Tang, Z.-Z., Liang, J., Guo, C. & Wang, Y.-X., 2012. Photogrammetry-based two-

dimensional digital image correlation with nonperpendicular camera alignment,

s.l.: Society of Photo-Optical Instrumentation Engineers.

Yoneyama, S. & Murasawa, G., 2013. Digital Image Correlation, Japan:

Encyclopedia of Life Support Systems.](https://image.slidesharecdn.com/42007b31-8bd2-4dcb-9861-cbefe989c049-160901171126/85/Final-Thesis-Report-64-320.jpg)