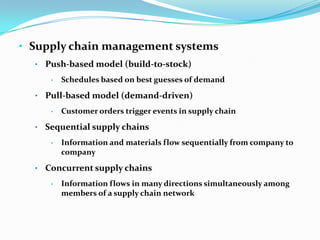

This document discusses supply chain management systems and strategies. It covers:

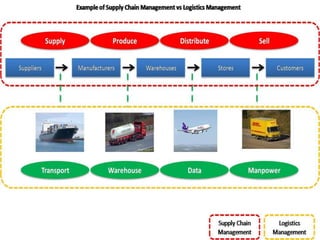

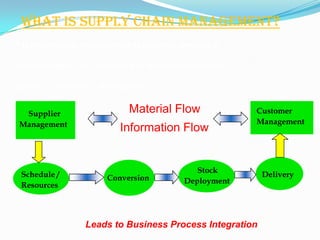

1. What a supply chain is and how it links suppliers, manufacturers, retailers, and customers.

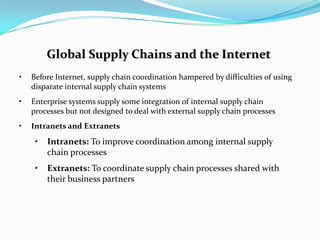

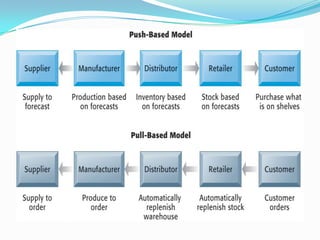

2. How supply chain management systems help manage relations with suppliers through constant information exchange.

3. Strategies like just-in-time to balance distribution and synchronize product flow with the aim of getting the right amount of products in the least amount of time at the lowest cost.

4. Walmart's supply chain strategy of strategic sourcing, cross-docking, and using technology to accurately forecast demand and track inventory.