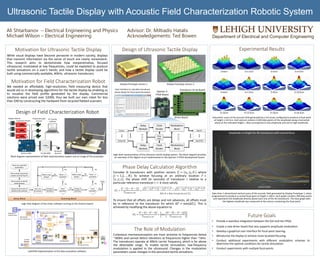

The document summarizes Ali Shtarbanov and Michael Wilson's research on an ultrasonic tactile display and accompanying field characterization robotic system. Their goals were to demonstrate how low-frequency modulated ultrasound could produce tactile sensations and build a tactile display using 40kHz transducers. They also built an affordable robotic system using recycled scanners to visualize and characterize the display's acoustic field, which aids algorithm development. Experimental results showed the robotic system could perform high-resolution 3D scans of ultrasound fields and focal points generated by the display prototypes.