This document provides descriptions of various types of equipment used for sample preparation in a laboratory setting, including:

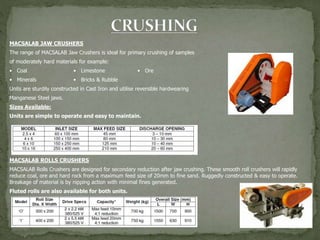

- Jaw crushers and roll crushers for primary and secondary crushing of samples like coal, limestone, and minerals.

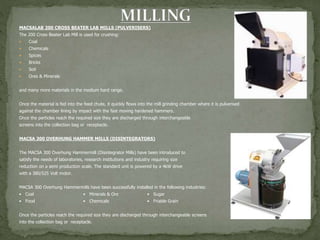

- Hammer mills and cross beater mills for pulverizing samples into fine particles using hammers or beaters.

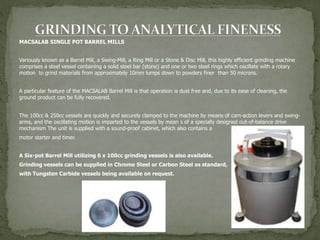

- Barrel mills that grind materials into powders using a rotating stone and rings in a dust-free vessel.

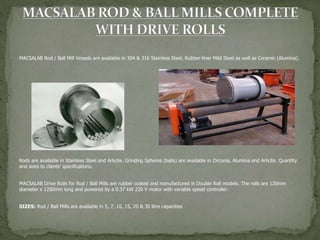

- Rod/ball mills with stainless steel, rubber-lined, or ceramic vessels for grinding with rods or balls.

- Cascade and micro splitters to divide samples into equal portions for testing using vibrating feeders and