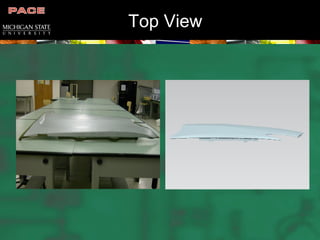

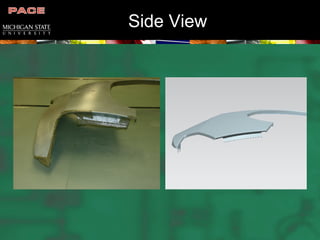

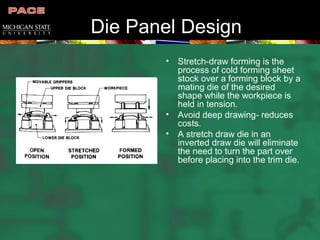

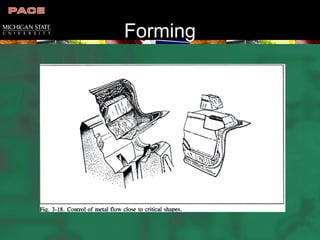

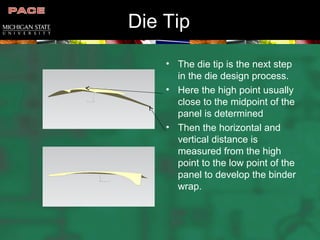

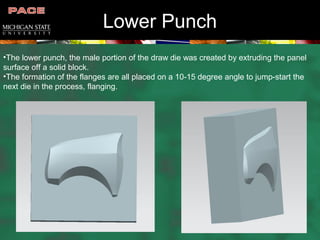

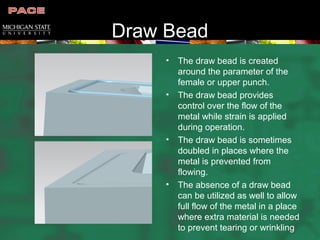

This document summarizes the design process for a die used to form a front quarter panel on a vehicle. It describes laying out the design, creating detailed drawings, programming the machine, and developing the individual die components like the upper and lower punches. It outlines three redesigns of the panel, including changes to the flanging. Finally, it provides details on specific die elements like the die tip, binder wrap, draw bead, and how they control material flow during the forming process.