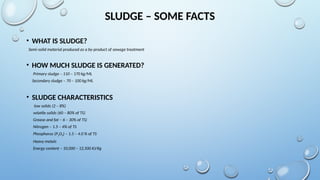

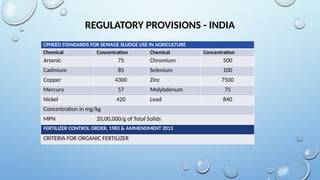

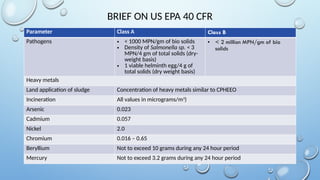

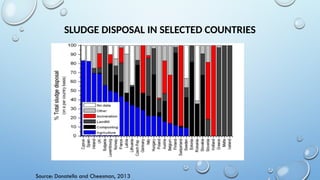

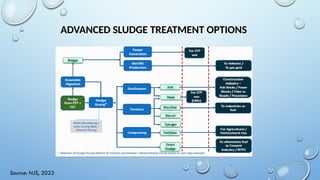

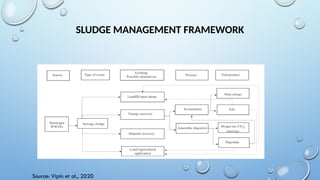

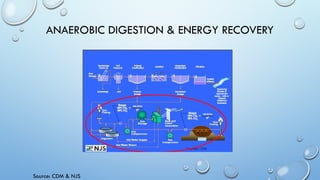

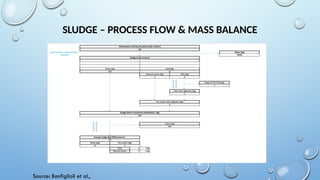

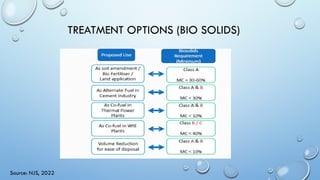

The document discusses biosolids management, specifically focusing on sludge characteristics, generation, regulatory provisions, and treatment processes. It outlines the sludge's properties, heavy metal concentrations, and different treatment options such as anaerobic digestion and incineration, and compares regulatory standards among various countries. The potential for energy recovery from sludge treatment processes and the importance of establishing standards for biosolids management are also highlighted.