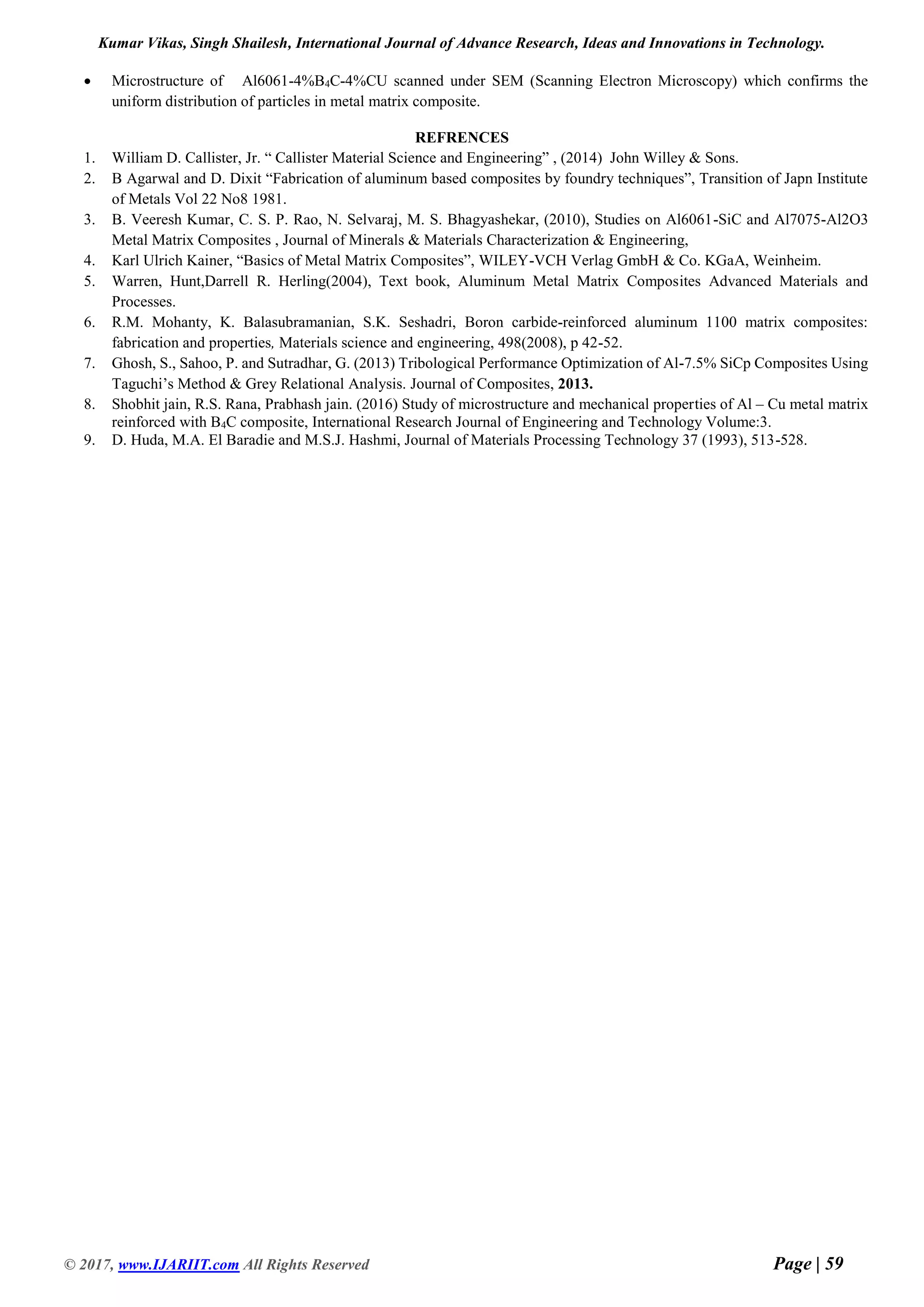

This document presents research on the fabrication and evaluation of aluminum 6061 reinforced with 4% boron carbide and 4% copper using the stir casting method. The study finds improvements in tensile strength and hardness by 20% and 15%, respectively, with a slight decrease in impact strength. Scanning electron microscopy confirms uniform distribution and microstructure of particles in the metal matrix composite, indicating suitability for automotive applications.