Experienced in Quality Control & Production

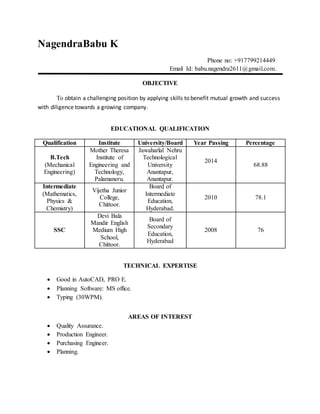

- 1. NagendraBabu K Phone no: +917799214449 Email Id: babu.nagendra2611@gmail.com. OBJECTIVE To obtain a challenging position by applying skills to benefit mutual growth and success with diligence towards a growing company. EDUCATIONAL QUALIFICATION Qualification Institute University/Board Year Passing Percentage B.Tech (Mechanical Engineering) Mother Theresa Institute of Engineering and Technology, Palamaneru. Jawaharlal Nehru Technological University Anantapur, Anantapur. 2014 68.88 Intermediate (Mathematics, Physics & Chemistry) Vijetha Junior College, Chittoor. Board of Intermediate Education, Hyderabad. 2010 78.1 SSC Devi Bala Mandir English Medium High School, Chittoor. Board of Secondary Education, Hyderabad 2008 76 TECHNICAL EXPERTISE Good in AutoCAD, PRO E. Planning Software: MS office. Typing (30WPM). AREAS OF INTEREST Quality Assurance. Production Engineer. Purchasing Engineer. Planning.

- 2. PROFESSIONAL EXPERIENCE Total Experience : 1 Year. Organization : Precision Profiles India. [A Leading manufacturer in Pressure equipment, Steel structures Fabrications and earth moving parts, Supplied to major companies that L&T (KPM unit, Business unit, Valves unit & ECC division) and Wind limited.] Designation : Quality & Production Engineer. Duration : From August 20th. ROLES RESPONSIBILITES As Production Engineer: Projects Handled: Customer : NPCIL-Check Valve (Size: 400mm & 600mm) Customer : Larson and Toubro Limited – (kpm unit) Tyre curing Press sub assembly parts Columns, main frame, steam box, rotating arm, main base Assembly and etc., Customer : Larson and Toubro Limited – (ECC division) Power plant erection tower project 4.8m tower columns, Trolley Assy, Recoliler Assy etc., Customer : Larson and Toubro Limited – (HED) Main base structure assembly and loaded testing fixture etc., Customer : L&T Valves VWS Values 300mm to 2800mm Customer : Win Wind Limited Wind Mill Projects Generator casing, Rotor lock segment Effective 4M planning to achieve production target. Monitoring the production and achieving the target. Well trained for to read the drawing and execute the same in the shop floor. Manpower training and maintaining the skill matrix record. To supervise and participates in non-destructive testing of equipment. To check the execution of Non-Destructive Tests and Heat Treatment and to keep a Record / Report on it. Prior to the start of works, to check the suppliers material and Technical Documentation delivery schedule. Check that the same is in line with construction schedule and Contractual Commitments Stage inspection and approval of process and procedures as described in relevant QAP’s. Using computer-aided design to create detailed designs and specifications

- 3. Comprehensive understanding of engineering and design principles. Understanding of computer-assisted design software i.e. 3D CAD. Experience of tolerance analysis and manufacturing drawings. Providing design support at all stages of the design process. Develop and maintain project plans using MS Project for allocated tasks. Involved in creating and planning new production processes. Considering issues such as cost, safety and time constraints. Checking drawings for accuracy and errors. By using MS-Office planning schedule, production chart & presenting the design. Organizing the Workers. Visual inspection and Orientation checking. As Quality Engineer: Inspection, Drawing reading use of Measuring Instruments e.g. Vernier caliper, Micrometer, Linear Height Gauge, Bore Gauge, Bore Now & Air Gauges, Surface Tester, Hardness Tester well versed Quality Techniques, ISO, 7QC Tools, 5s, & Kaizan. Giving technical clearance to the materials for the procurement. Raw Material receiving inspection, review of material Certificates to check mechanical strength and chemical composition values in accordance with ASME codes. Monitor and carry out day to day fabrication and inspection activities such as marking, cutting, edge preparation, fit - up, welding and assembly work. Review all applicable documents prior to start welding activities such as approved method of statements, inspection test plan, welding procedure specifications, material specifications, drawings, NDE matrix, codes and standards. Verify that the welders, welding operator and tack welders have been properly qualified and the welding is performed in accordance with applicable codes, standards, specifications and drawing. Monitoring on process welding, pre-heat, process variables and heat input calculation if applicable. Review of the welder qualification test report. Review the maintenance record for consumables. Prepare material / Weld traceability, inspection report and control of documents for regular inspection activities. Perform the CNC program by using FASTNEST software. Review / maintain calibration records of Instruments. Review RT, UT, MT & PT reports as per ASME Code.

- 4. Checking the assembly of components with drawings. Documenting stage wise inspection and preparing the consolidated report. Carry out the final inspection, together with Client / Third party Inspector upon completion of all welding works. PROJECT EXPERIENCE Title : Design and Fabrication of Hybrid Turbine (INNOVATIVE). Aim : To Reduce Installation Cost, Fabrication and Manufacturing cost. Role : Team Leader. CO-CURRICULAR ACTIVITIES Participated in NATIONAL CONFERENCE ON ADVANCES IN MECHANICAL ENGINEERING. Participated in 2nd NATIONAL LEVEL CONFERENCE by VIT PRAGNA-2K13 (2013). Participated In Workshop on Auto Cad. RESPONSIBILITIES HELD Team Leader, Workshop Coordinator, NSS. KEY STRENGTHS Self-motivated, Adaptability, Initiative, Quick Learner. PERSONAL INFORMATION Father’s Name : K.Venkatesh Date of birth : 26/11/1992 Gender : Male Languages known : Telugu (S,R,W), English (S,R,W), Tamil(S) Marital status : Unmarried DECLARATION I declare that the Information furnished above is true to the best of my Knowledge and belief. Place : Bangalore Date : (K. Nagendra Babu)