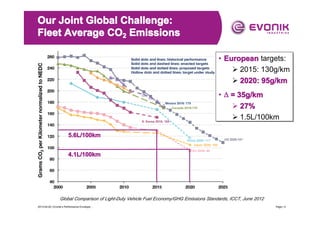

The document compares formulations for 75W-140 axle oils containing VISCOBASE 11-522 or PAO100 base stocks. Bench tests show the VISCOBASE formulation provides better friction performance under mixed lubrication and EHL modes compared to the PAO100 formulation, with lower friction coefficients measured. The VISCOBASE formulation also meets the SAE J306 viscosity specifications for 75W-140 oils while providing enhanced viscosity index and thermal properties versus the PAO100 alternative and a commercial 80W-90 reference oil. The document promotes VISCOBASE 11-522 as a cost-efficient alternative for axle oils that can improve fuel economy through reduced friction.

![ATF Formulations

6.0cSt

Conventional

PAMA

6.0cSt

VISCOPLEX®

12-199 (Comb)

4.5cSt

VISCOPLEX®

12-199 (Comb)

VII [%]

8.5

5.7

3.5

VISCOPLEX® 1-180 [%]

0.3

0.3

0.3

DI package [%]

15.0

15.0

15.0

Nexbase 3030 [%]

76.2

79.0

30.0

Nexbase 3020 [%]

-

-

51.2

KV100 [mm²/s]

6.03

6.02

4.48

5.46

KV40 [mm²/s]

28.4

24.7

17.1

26.0

VI

166

210

193

152

BF [mPas]

10,200

6,600

2,900

7,900

PP [°C]

-48

-48

< -48

-45

KV100KRL20 [mm²/s]

5.71

5.70

4.35

5.35

KV100 loss [%]

5.3

5.4

2.9

2.1

PSSI

18

18

15

-

2013-04-20 | Evonik’s Performance Envelope ...

5.5cSt

Hyundai

SP-IV FF/SF

Page | 16](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-16-320.jpg)

![New European Driving Cycle (NEDC)

80

150

ECE* 3+4

Urban Driving

Cycles

EUDC Extra

Urban Driving

Cycle

60

100

40

5.5cSt FF/SF (2)

50

20

0

0

200

400

600

800

1000

Vehicle speed [km/h]

Transmission oil temperature [

]

ECE* 1+2

Urban Driving

Cycles

0

1200

Time [s]

* ECE = Economic Commission for Europe

2013-04-20 | Evonik’s Performance Envelope ...

Page | 18](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-18-320.jpg)

![Fuel Consumption by Sub-cycle

12

.8

12 7

.8

12 3

.5

3

14

6.0cSt Conventional

6.0cSt Comb

4.5cSt Comb

5.5cSt FF/SF

12

10

8.

62

8.

52

8.

49

8.

54

11

10

.2

10 9

.1

10 9

.1

2

9

88

6.

78

6.

83

8

6.

Fuel consumption [L/100km]

13

7

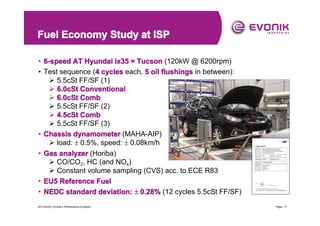

• Comb polymer (in

parallel to KV100

lowering) reduces

fuel consumption

in NEDC and its

ECE sub-cycles

• In EUDC, the 4.5cSt

fluid shows

increased fuel

consumption due to

mixed lubrication

6

ECE 1+2

2013-04-20 | Evonik’s Performance Envelope ...

ECE 3+4

EUDC

NEDC

Page | 19](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-19-320.jpg)

![NEDC Fuel Economy

2.0

2.0

1.5

NEDC FE vs. 5.5cSt

SF/FF [%]

NEDC FE vs. 6cSt

Conventional [%]

1.6

1.2

1.0

0.5

0.0

6.0cSt Comb

4.5cSt Comb

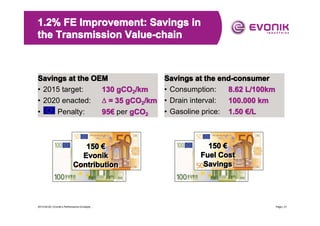

• 6.0cSt Comb delivers 1.2% FE vs

6.0cSt Conventional

• Lowering KV100 to 4.5cSt results

in 1.6% FE totally (mixed

lubrication!)

2013-04-20 | Evonik’s Performance Envelope ...

1.5

1.0

0.5

0.3

0.0

6.0cSt Comb

• 6.0cSt Comb delivers 0.3% FE vs

5.5cSt FF/SF, but at higher KV100

implying higher wear and fatigue

protection

Page | 20](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-20-320.jpg)

![75W-140 Formulations

75W-140 w/

VISCOBASE®

11-522

75W-140 w/

PAO100

80W-90 Intertek

Reference

SAE J306 JUN2005

Base stock [%]

47.0

57.0

DI package [%]

4.0

4.0

PAO4 [%]

29.0

19.0

Ester, 3.6cSt [%]

20.0

20.0

KV100 [mm²/s]

25.8

25.3

13.7 (non

stay-in-grade)

13.5-18.5 (80W-90)

24-32.5 (75W-140)

KV40 [mm²/s]

170

183

117

VI

187

171

114

BF [mPas]

89,400 (-40°C)

128,000 (-40°C)

35,900 (-26°C)

<150,000

KV100KRL20 [mm²/s]

24.7

25.0

12.0

13.5-18.5 (80W-90)

24-32.5 (75W-140)

KV100 loss [%]

4.3

1.0

11.8

PSSI

5.1

1.1

2013-04-20 | Evonik’s Performance Envelope ...

Page | 24](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-24-320.jpg)

![Bench Testing: MTM Mixed

Lubrication & EHL Modes

0.10

0.05

75W-140 VISCOBASE ® 11-522

75W-140 PAO100

30N

2000mm/s

0.04

120

Friction coefficient

Friction coefficient

0.08

®

®

75W-140 VISCOBASE 11-522

75W-140 PAO100

0.06

25

0.04

30N

50%SRR

0.02

0.00

0.03

25

40

60

0.02

80

100

120

0.01

0.00

1

10

100

1000

Mean speed [mm/s]

10000

0

10

20

30

40

50

SRR [%]

• Note highly resolved y-axes!

• VISCOBASE® 11-522 and

PAO100 show same friction

coefficient in MTM mixed

lubrication and EHL modes

2013-04-20 | Evonik’s Performance Envelope ...

Page | 25](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-25-320.jpg)

![Bench Testing:

FZG Efficiency and ARKL

10

80

®

®

75W-140 VISCOBASE 11-522: feff = 0.97

75W-140 PAO100: f eff = 0.97

]

60

6

Temperature [

Torque loss [Nm]

8

20

4

44

90

2

feffciency = 1 -

torque /

temperature,

load stage

100

200

Torque [Nm]

20

75W-140 VISCOBASE? 11-522: Tequ = 62

75W-140 PAO100: T equ = 64

loss

temperature,

load stage

0

0

40

300

0

0

100

200

300

400

Time [min]

• VISCOBASE® 11-522 and

PAO100 show same

performance in FZG

efficiency and ARKL tests

2013-04-20 | Evonik’s Performance Envelope ...

Page | 26](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-26-320.jpg)

![GM 900 Axle Efficiency Test

at Intertek

800

28 kW 51 kW

16 kW

600

91 kW

165 kW

#29

Torque [Nm]

#17

Potential

operating

range

400

9 kW

Typical operating

range acc. to CAFE

(Corporate Average

Fuel Economy)

5 kW

200

3 kW

1 kW

0

0

#15

#3

1000

2000

3000

Pinion speed [rpm]

“29/20 Schedule”

Schedule”

• 29 stages over 8 constant power lines, 9 calibration stages outside of window

• 20 stages used for analysis, focus on stages #3, #15, #17, #29

• Each point held for 10 min (efficiency computed from last 5 min)

2013-04-20 | Evonik’s Performance Envelope ...

Page | 27](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-27-320.jpg)

![Constant Temperature Mode (49°C)

(49°

100

75W-140 VISCOBASE? 11-522

98.4

75W-140 PAO100

98.4

98.5

98.6

98

Efficiency [%]

96.1

96

96.0

• VISCOBASE®

11-522 and

PAO100 show

same efficiency

throughout all

stages

94

92

91.2

91.3

90

#3 (54Nm,

500rpm)

2013-04-20 | Evonik’s Performance Envelope ...

#15 (54Nm,

2900rpm)

#17 (542Nm,

500rpm)

#29 (542 Nm,

2900rpm)

Page | 29](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-29-320.jpg)

![Stabilized Temperature Mode

100

75W-140 VISCOBASE? 11-522

98.6 98.6 98.5

99.0 99.0

75W-140 PAO100

98

97.4

80W-90 Reference

Efficiency [%]

96.3

96

95.3 95.5

94

93.5

92.9 92.9

92

90

120

#3 (54Nm,

500rpm)

#15 (54Nm,

2900rpm)

#17 (542Nm,

500rpm)

#29 (542 Nm,

107 105 105

2900rpm)

Stabilized temperature [

]

100

80

66

58

60

40

66

36

34

54

54

• VISCOBASE® 11-522 and

PAO100 show same

efficiency throughout all

stages

• GM 900 Axle Efficiency

Test discriminates

precisely (80W-90 shows

expected behavior

compared to 75W-140)

51

33

20

0

#3 (54Nm,

500rpm)

2013-04-20 | Evonik’s Performance Envelope ...

#15 (54Nm,

2900rpm)

#17 (542Nm,

500rpm)

#29 (542 Nm,

2900rpm)

Page | 30](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-30-320.jpg)

![Spin-loss Experiment

• Torque required to overcome axle

resistance, i.e. the friction due to

� oil churning (splashing) losses

� shaft seal losses

� windage losses

• No load

• Constant temperature at 48.9°C

• Speed range as in 29/20 schedule

• VISCOBASE® 11-522 and PAO100

show same spin-loss induced

torque

4

Spin-loss induced torque [Nm]

• Same axle as in efficiency test, but

use of high precision (low torque)

meters

75W-140

PAO100

75W-140

®

VISCOBASE

11-522

3

80W-90

Reference

2

1

0

1000

2000

3000

4000

Pinion speed [rpm]

2013-04-20 | Evonik’s Performance Envelope ...

Page | 31](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-31-320.jpg)

![Oxidative Stability

VISCOBASE® 11-522

+ 0.6% aminic/

as is

phenolic mixed AO

486

BV100 [mPas]

US Steel @121°C

(ASTM D2893-B)

PAO100

101

548 (13%)

536 (11%)

208 (106%)

∆TAN [mgKOH/g]

Pressurized DSC

(ASTM D6186)

Induction time @…

BV100’ [mPas]

0.12

0.0

14.2

…155°C [min]

>120

65

…180°C [min]

>120

<10

…210°C [min]

10

100

80

• VISCOBASE® 11-522

w/o detriments vs

PAO100

TGA weight [%]

140

160

180

60

40

?

75W-140 VISCOPLEX 11-522: 82.1%

75W-140 PAO100: 87.9%

20

0

2013-04-20 | Evonik’s Performance Envelope ...

0

60

120

Time [min]

180

Page | 32](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-32-320.jpg)

![Summary

VISCOPLEX® 12-199

Comb Polymer for

Your Fuel Economy ATF

VISCOBASE® 11-522 is

Your Cost-efficient

Alternative for Axle Oils

100

75W-140 VISCOBASE? 11-522

98.4

75W-140 PAO100

98.4

98.5

98.6

98

1.2% FE

Efficiency [%]

96.1

96

96.0

94

92

91.2

91.3

90

#3 (54Nm,

500rpm)

2013-04-20 | Evonik’s Performance Envelope ...

#15 (54Nm,

2900rpm)

#17 (542Nm,

500rpm)

#29 (542 Nm,

2900rpm)

Page | 34](https://image.slidesharecdn.com/evonikdrivelinecostefficient2013-131124050802-phpapp01/85/Evonik-driveline-cost-efficient-2013-34-320.jpg)