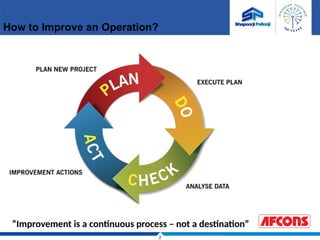

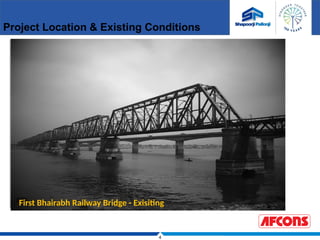

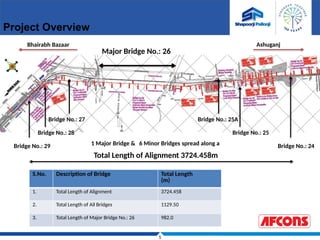

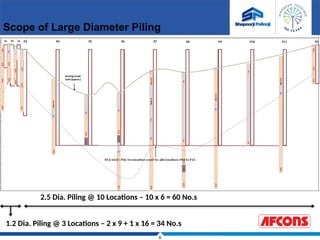

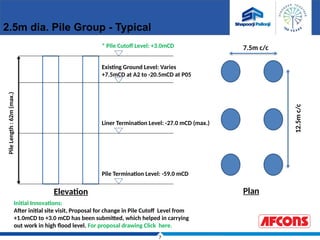

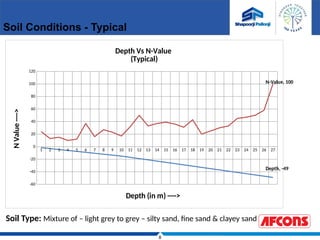

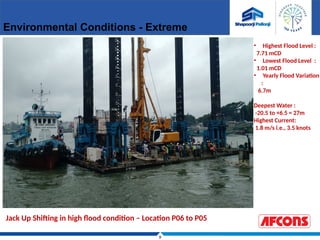

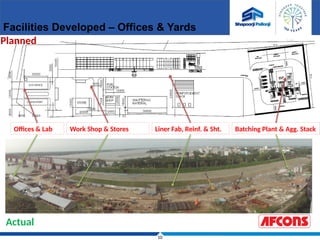

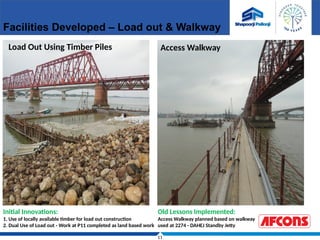

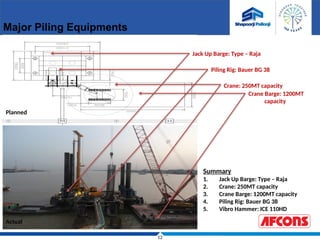

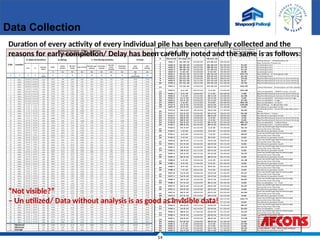

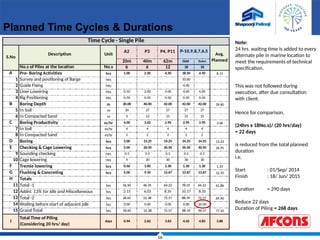

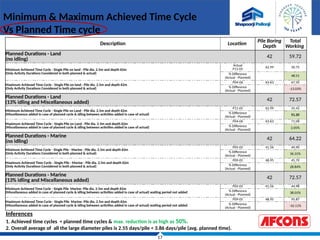

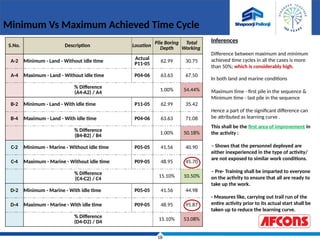

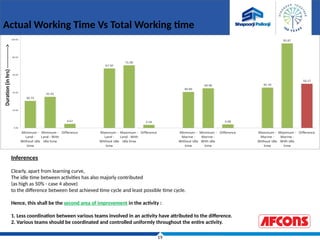

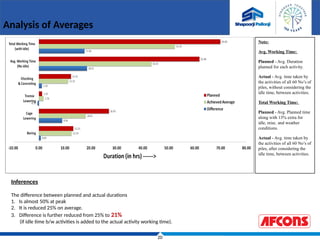

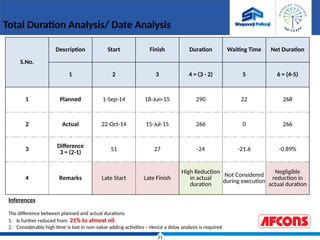

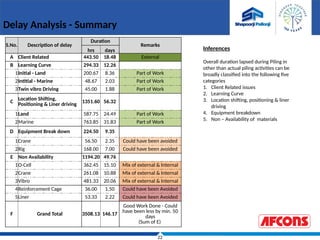

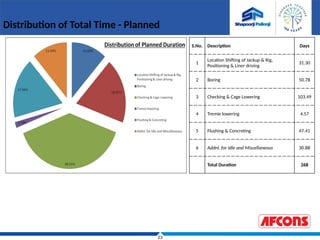

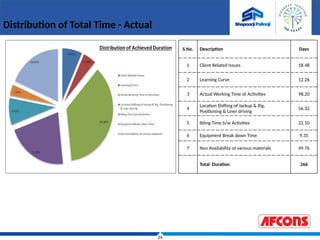

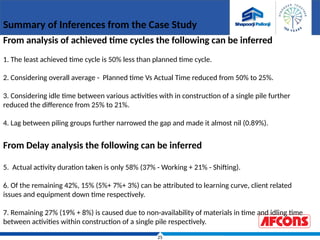

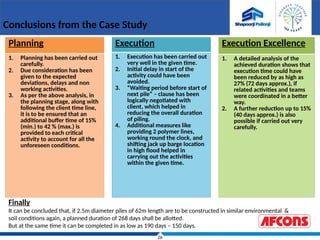

The document details a case study on large diameter piling for a project in Bangladesh, focusing on productivity analysis and operational improvements. It includes project specifications, environmental conditions, sequence of piling activities, and factors affecting productivity such as equipment availability and site conditions. The analysis emphasizes the importance of continuous improvement and learning from past challenges to enhance operational excellence.