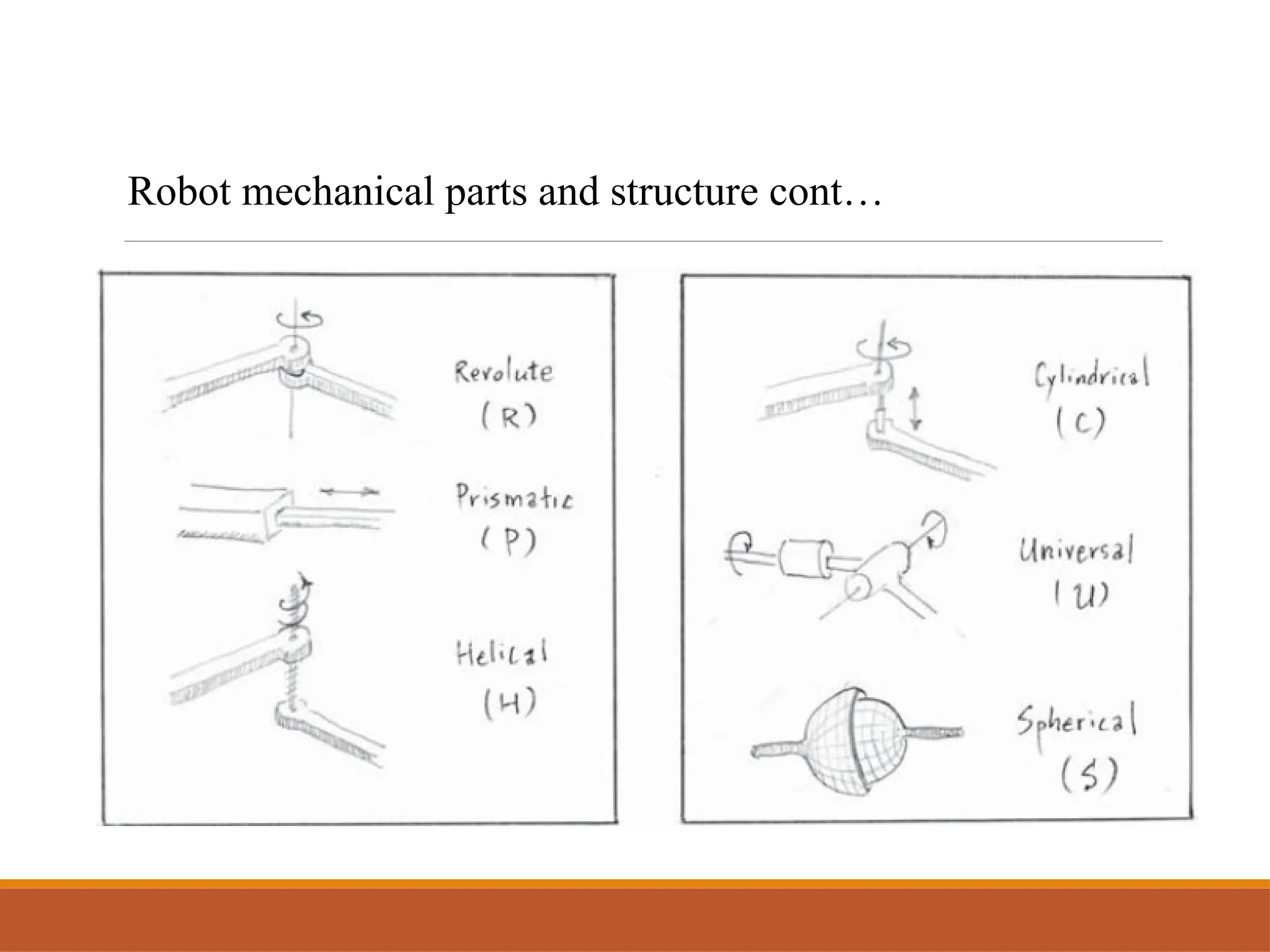

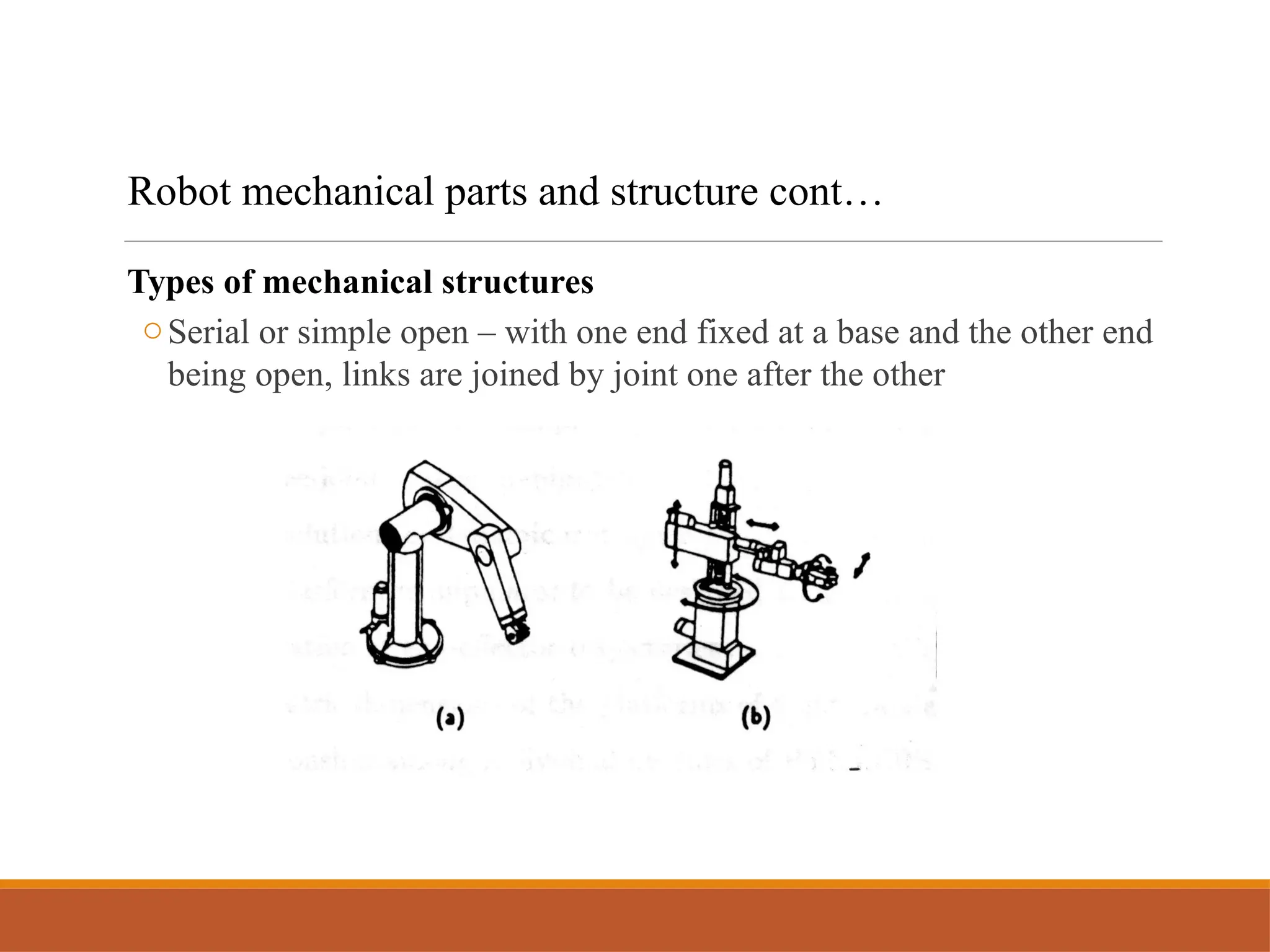

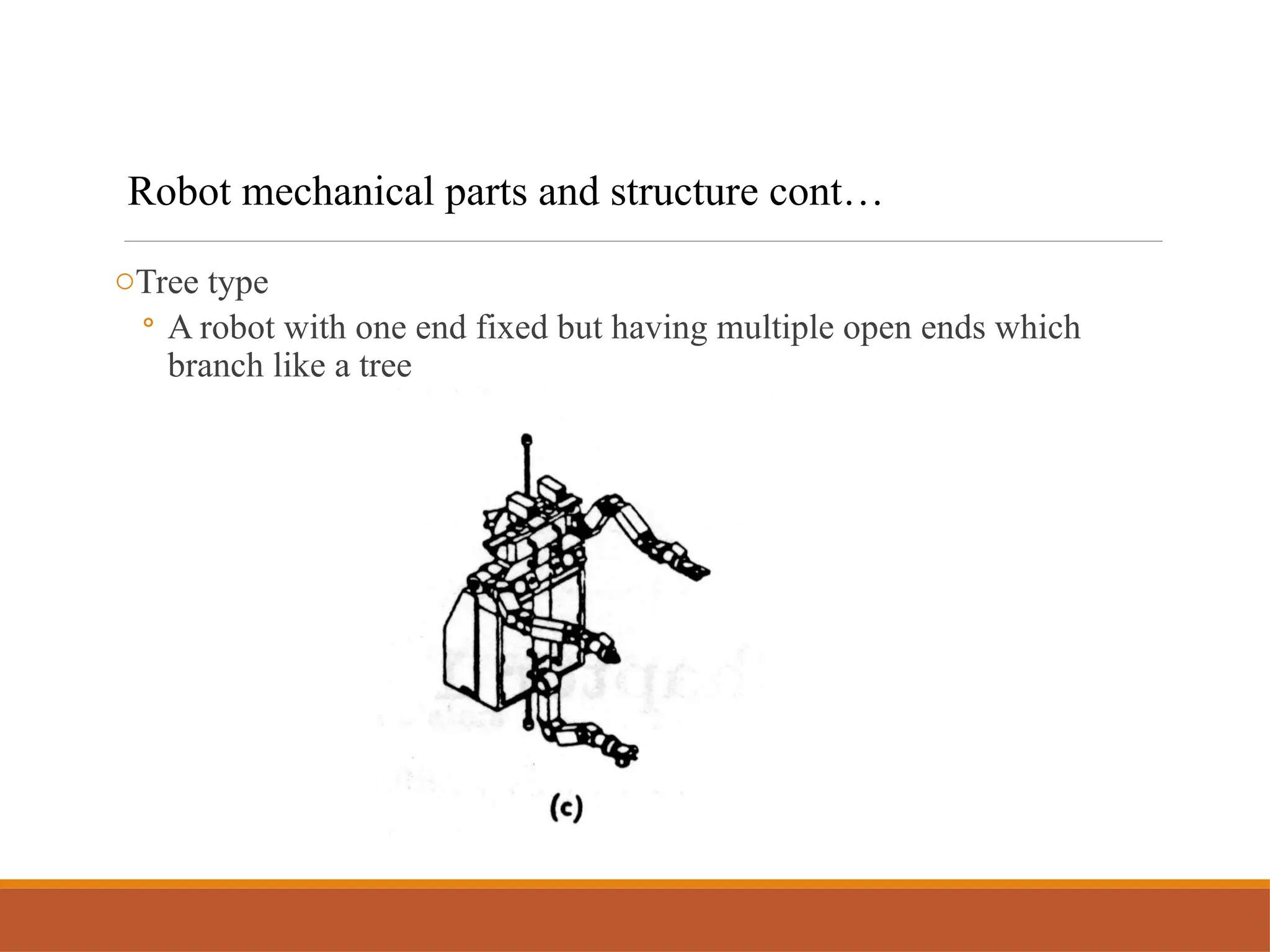

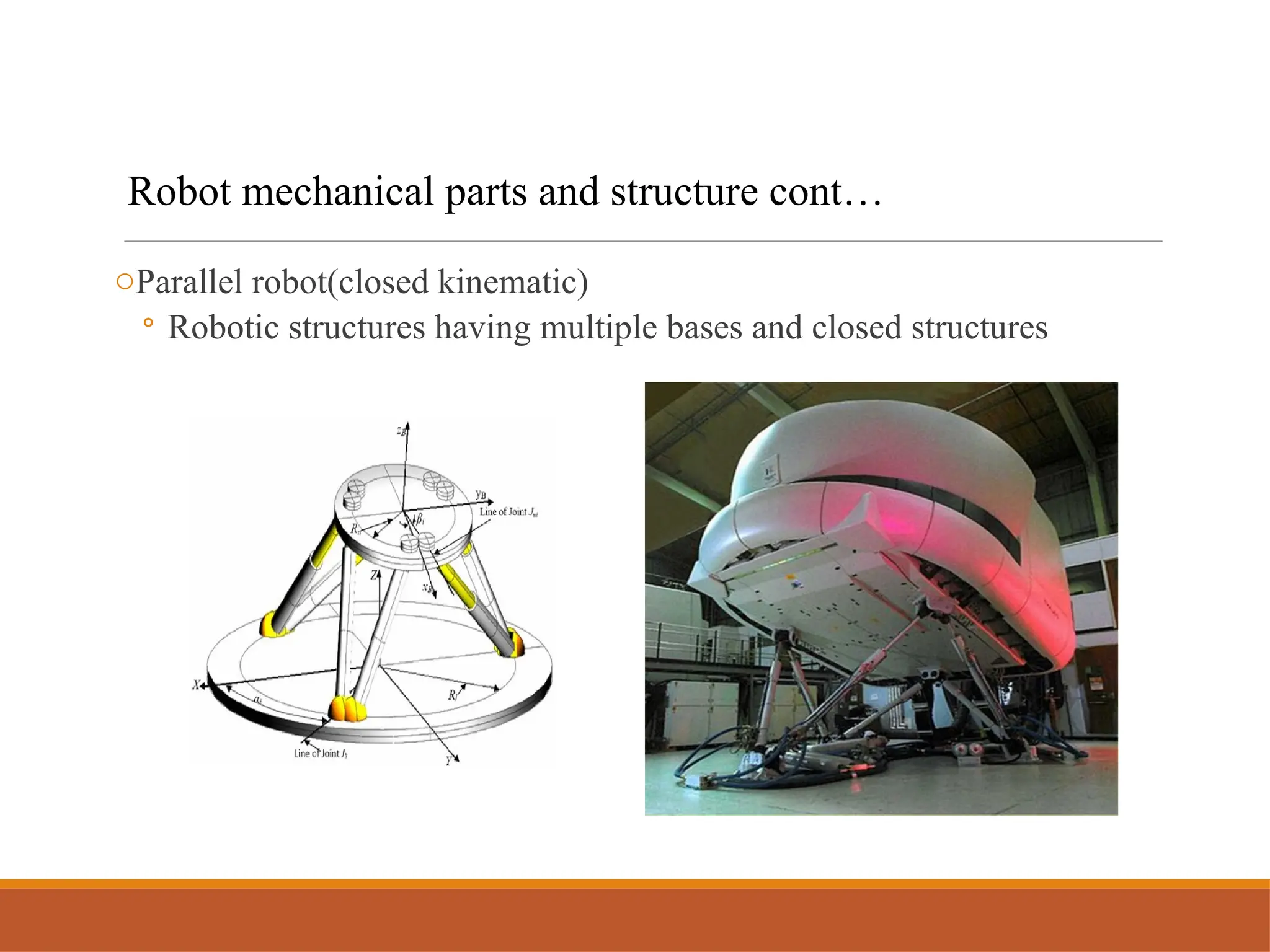

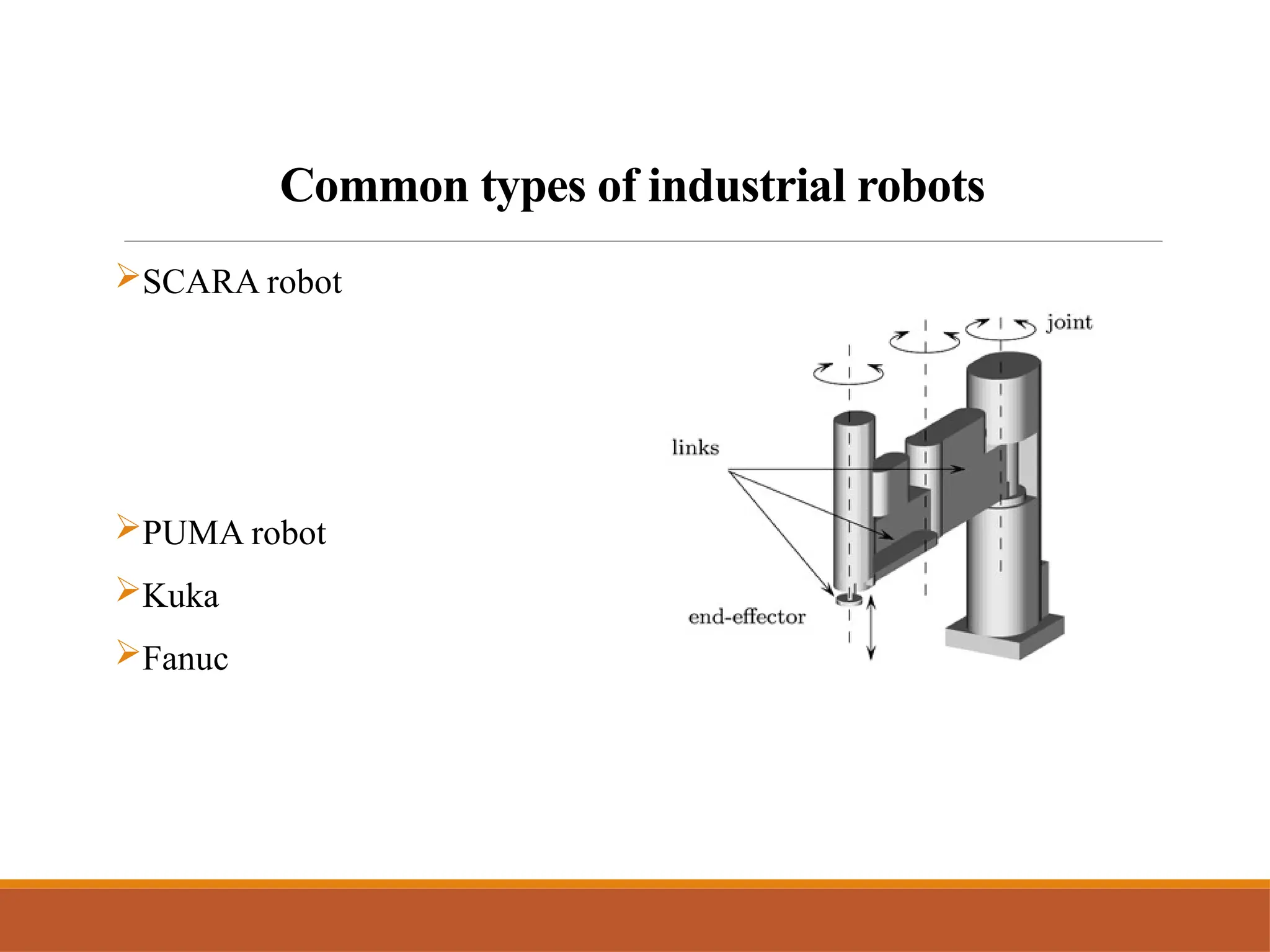

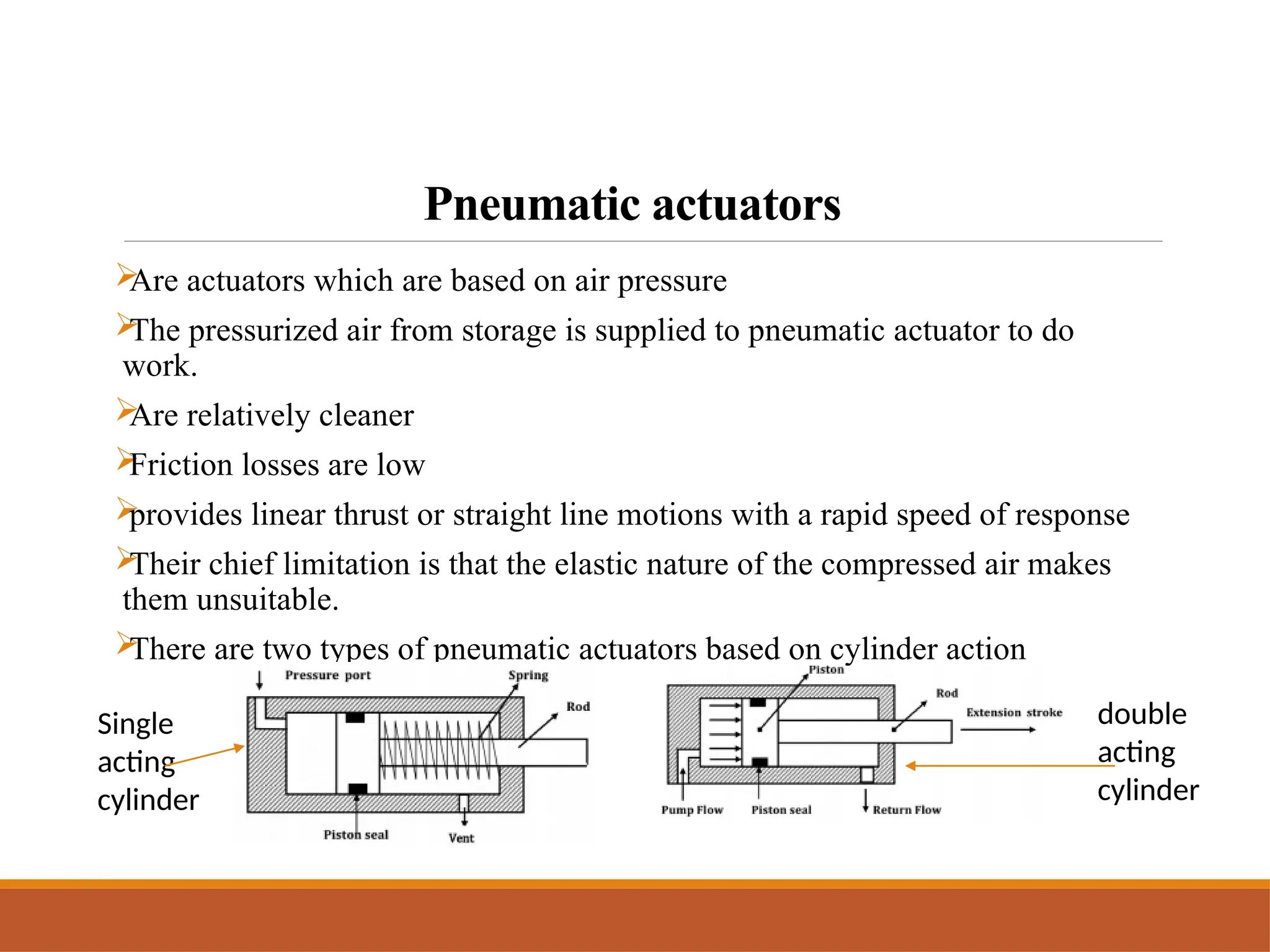

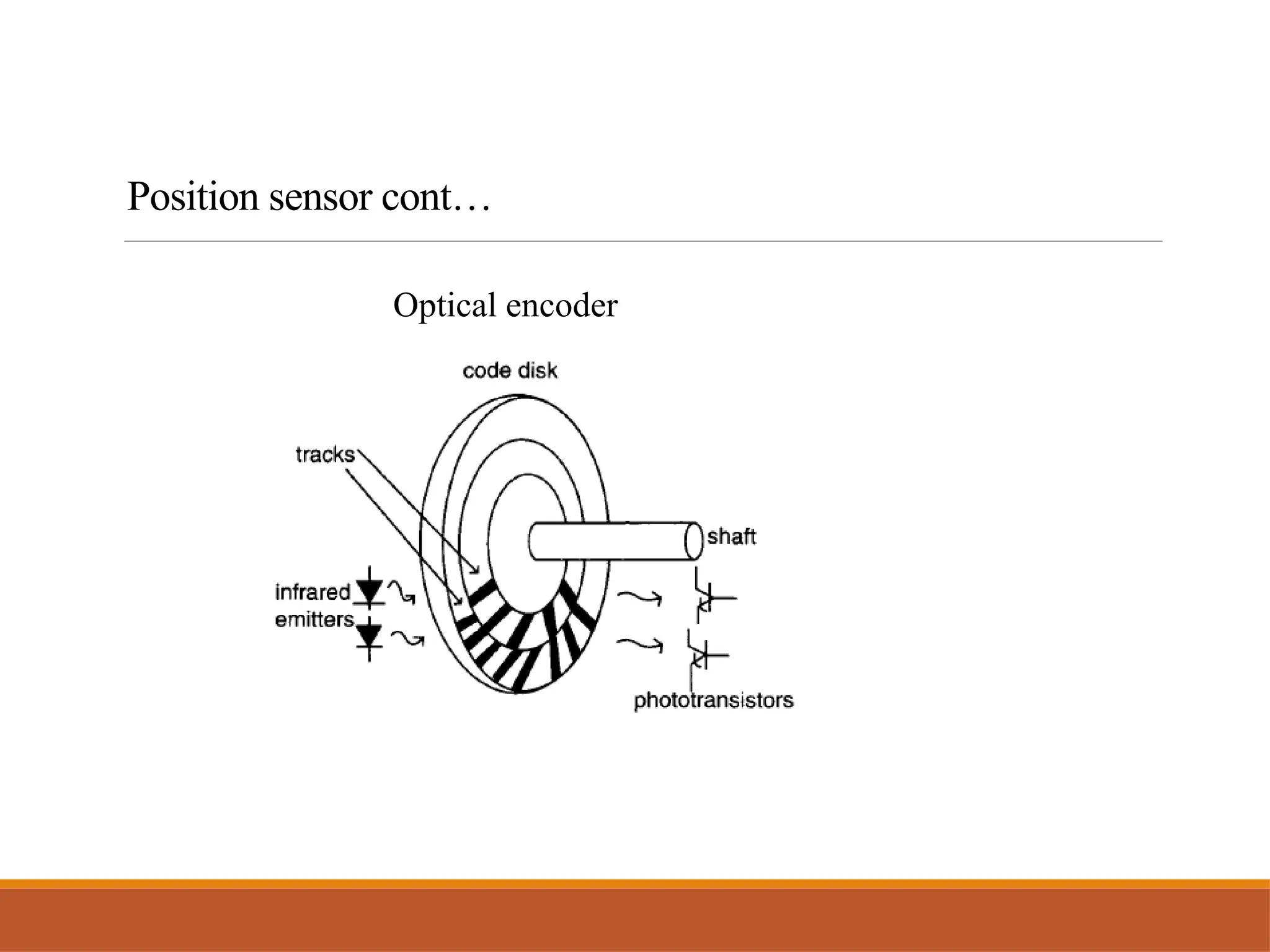

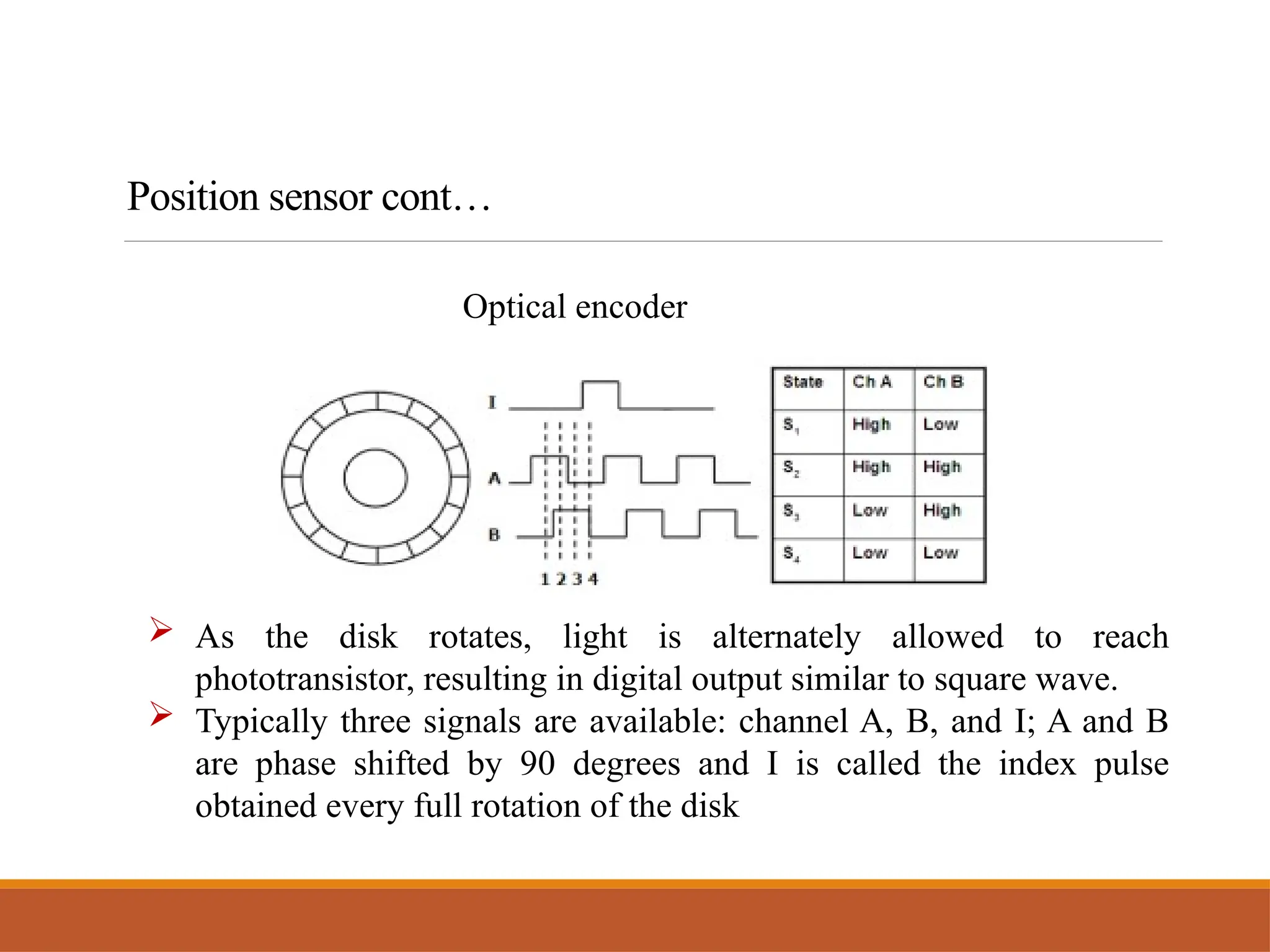

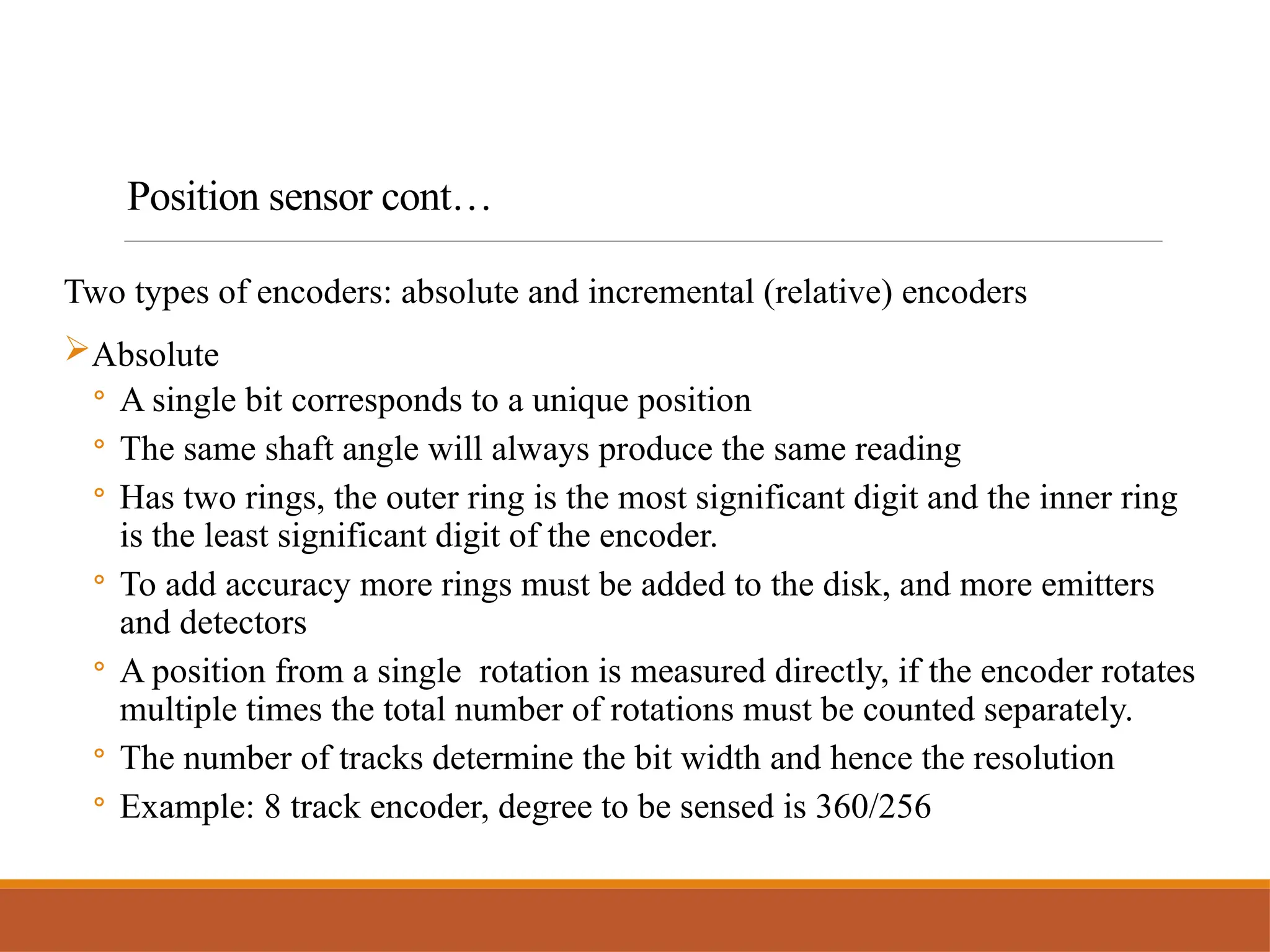

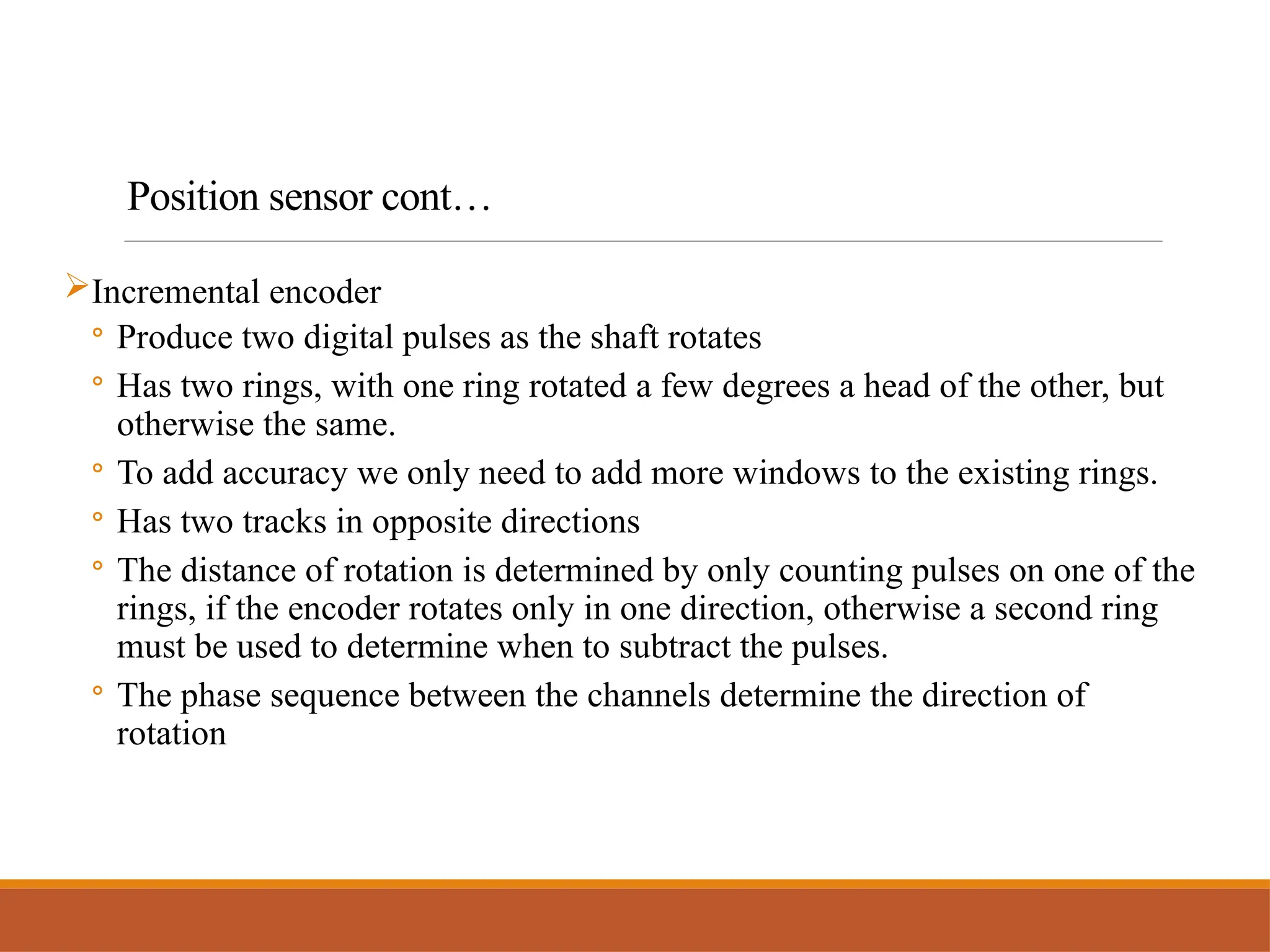

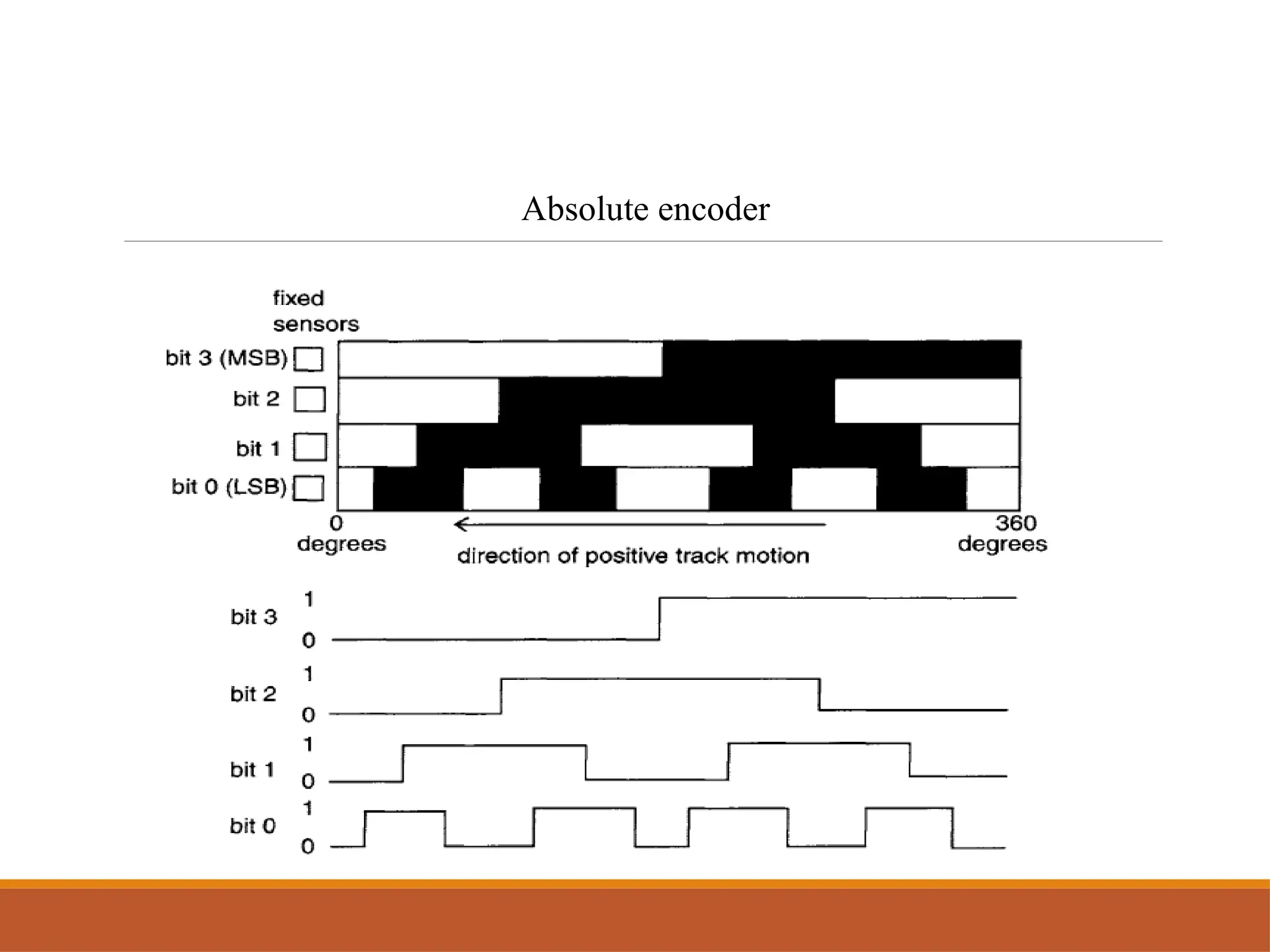

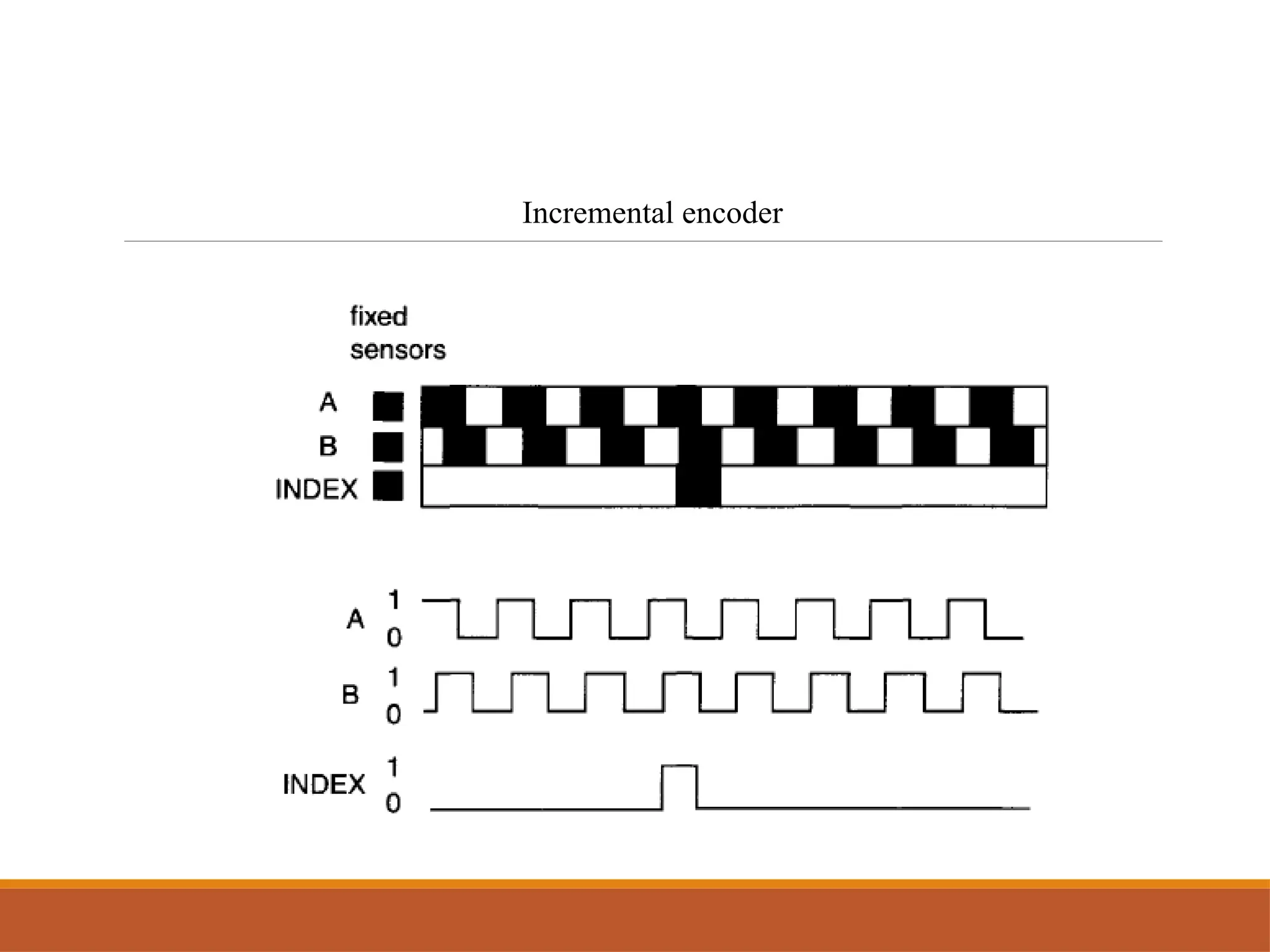

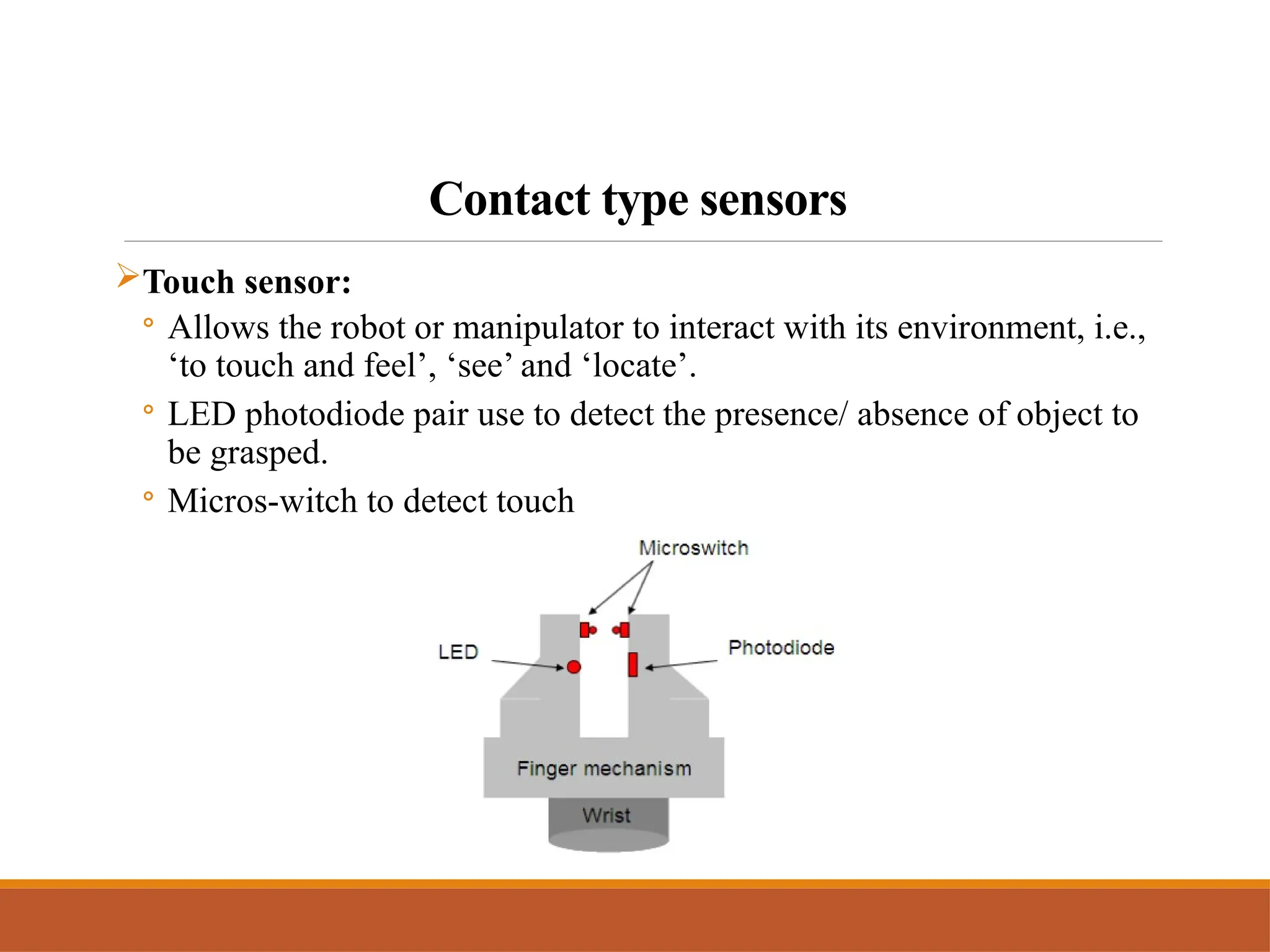

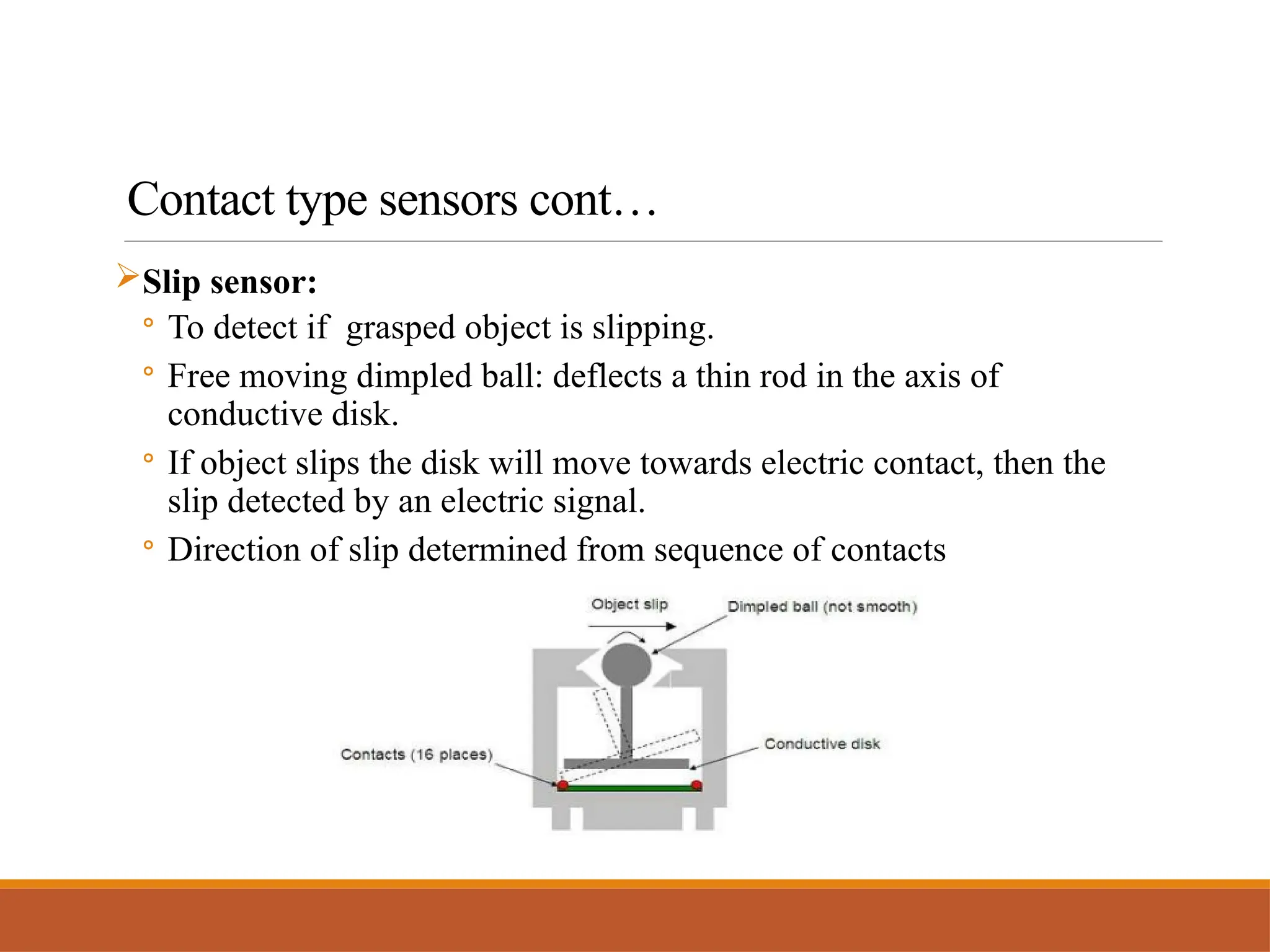

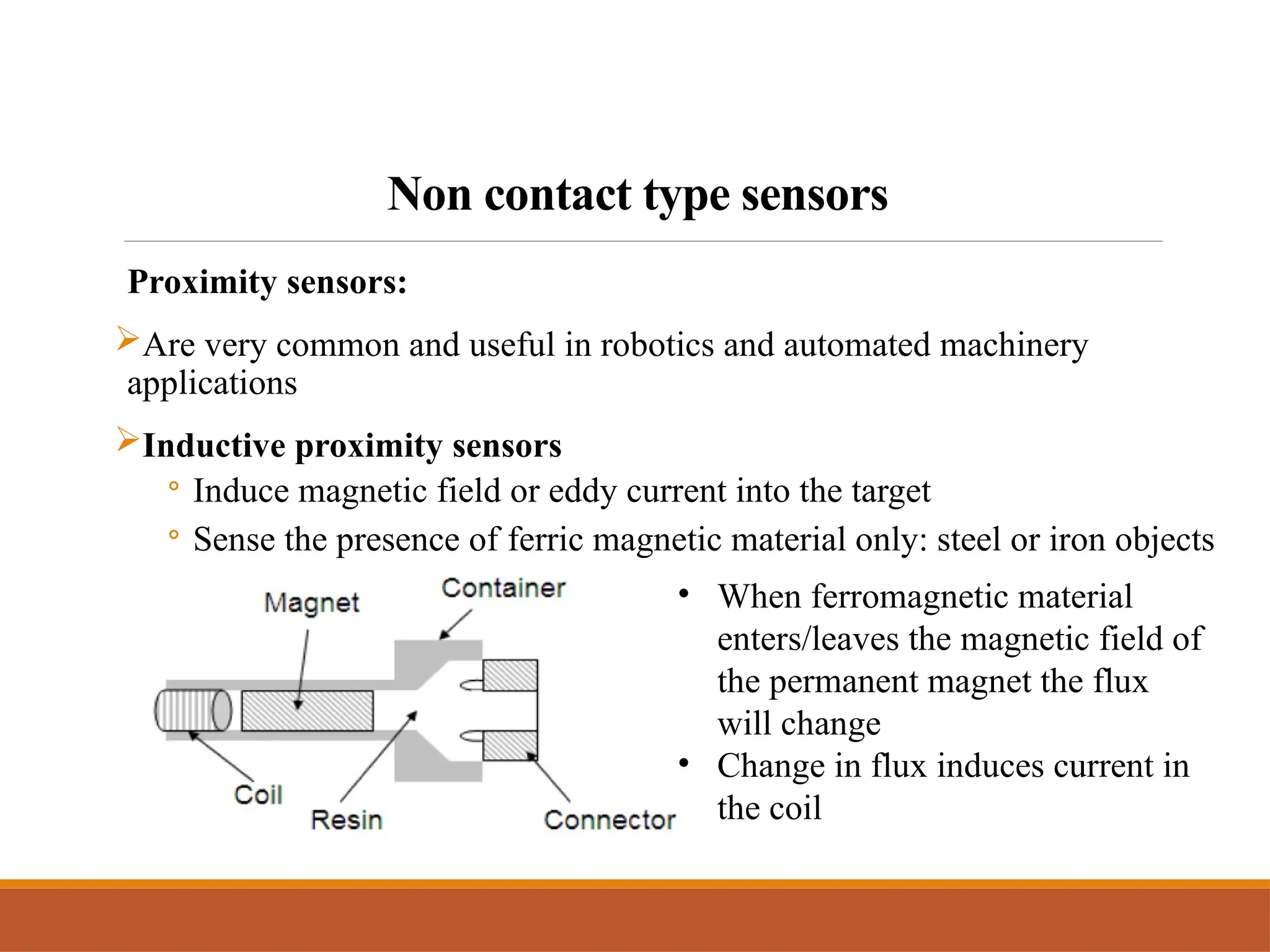

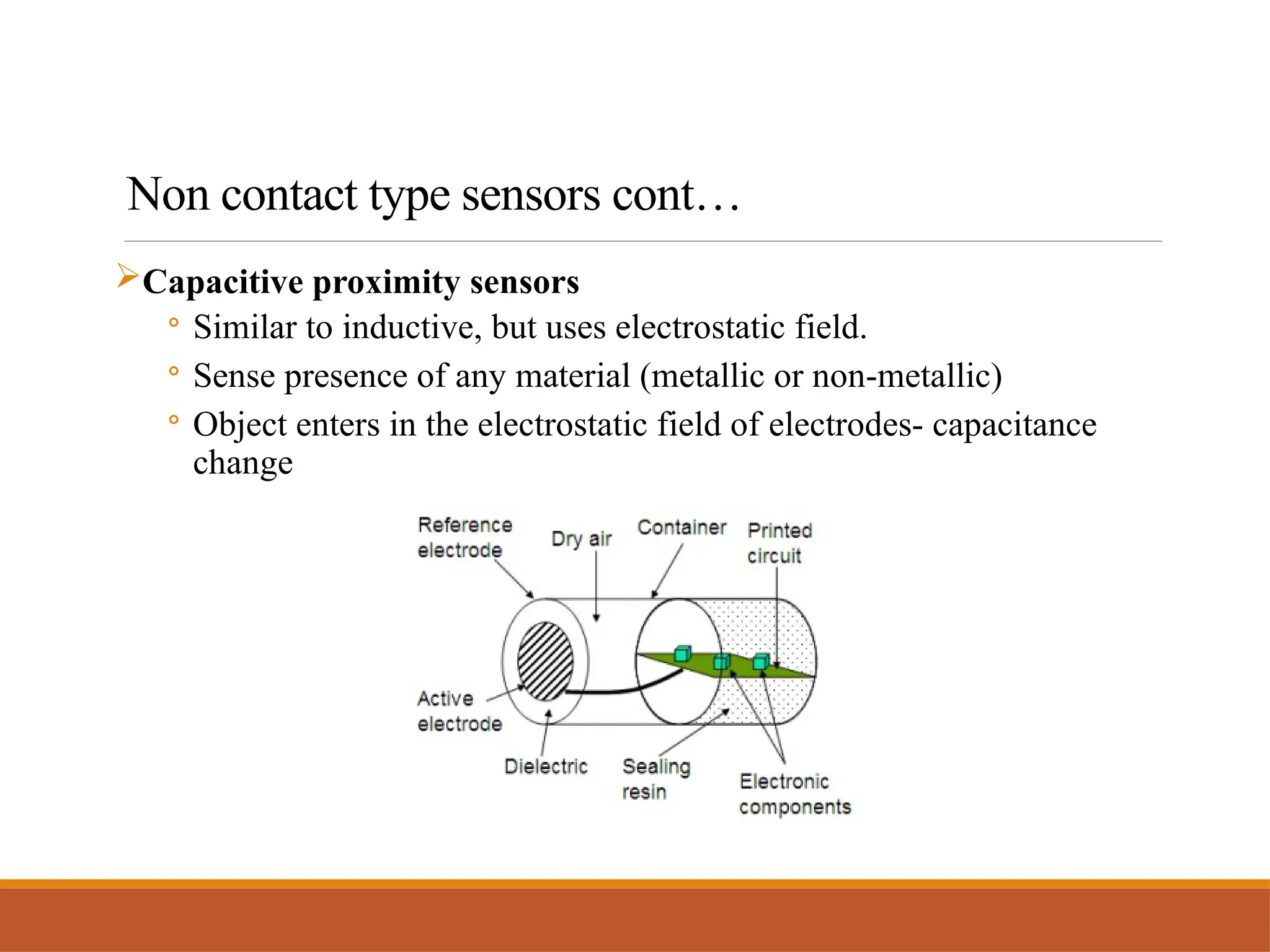

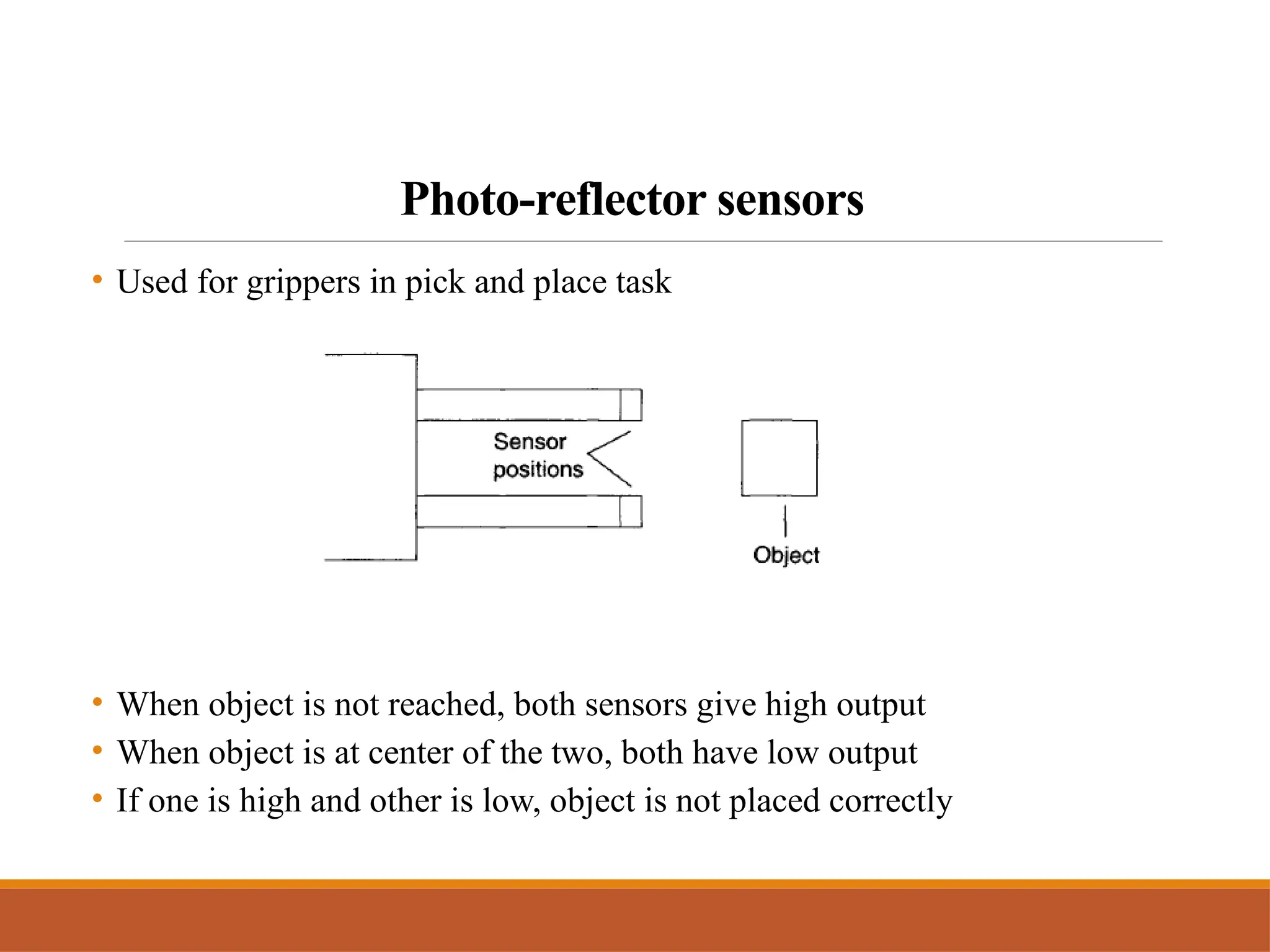

This document introduces robotics, defining robots as automated machines that perform specific tasks with functionalities ranging from industrial automation to medical applications. It covers various robot types, their mechanical structures, and components such as actuators and sensors, detailing the specifications and functions of each. Additionally, the document explores the significance and usage of both internal and external state sensors in robotic systems, highlighting their role in enhancing robot capabilities.